Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-07

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-07 Specification

- Seal Material

- Viton O-rings

- Grade

- Industrial

- Sensor Type

- Wet/Wet Differential Pressure Sensor

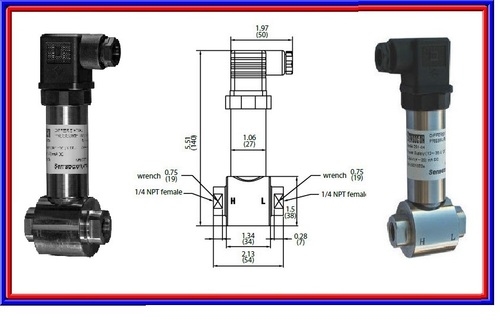

- Outer Size

- Approximately 120mm x 80mm x 55mm

- Display

- No local display

- Thread

- 1/4 NPT Female Connectors

- Material

- Anodized Aluminum Housing

- Processing Type

- Electronic/Signal Processing

- Mount Type

- Wall/Panel Mount

- Scale Range

- 0-250psid

- Accuracy

- 1% Full Scale

- Finishing

- Powder coated enclosure

- Measure Pressure Of

- Liquids and Gases

- Accessories

- Mounting bracket included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-07 Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- North America, Eastern Europe, Western Europe, Africa, Central America, Australia, Middle East, South America, Asia

- Main Domestic Market

- All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-07

The Series 251 wet/wet differential pressure transmitter utilizes a double diaphragm sensor technology that outperforms standard double sensor products in accuracy, reliability and static operating pressure. This differential pressure sensing technology offers 0.25% accuracy with static operating pressures up to 1000 PSI. The Series 251 features 316 stainless steel construction designed to meet NEMA 4X (IP 65) standards. The transmitter also offers exceptional field flexibility with a 5:1 turn down and comes standard with a certificate of calibration.

- Media compatibility: Gas and Liquids compatible with 316SS

- Accuracy: +/- 0.25% F.S.

- Over Pressure: positive - 2x f.S.; negative-1x F.S.

- Working Pressure: 1000 PSI (7MPa)

- Temperature Limits: Operating: -40° to 185°F (-40° to 85°C)Compensated: -4° to 158°F (-20° to 70°C)

- Thermal Effect: +/- 0.028% FS/°F (0.050%FS/°C)

- Stability: +/- 0.5% FS/year

- Power Supply: 12-30 VDC

- Output Signal: 4-20 mA, 2-wire

- Electrical Connetction: mini DIN 43650

- Response Time: 100 ms

- Turn Down: 5:1

- Enclosure Rating: NEMA 4X (IP 65)

- Process Connection: 1/4" NPT female, optional 1/4" G

- Mounting Position Effect:0.1% F.S., can be corrected by zero adjust

- Model Number : 251-07

- Range: 0 - 150 PSI ( 1034 kPa )

Reliable Wet/Wet Differential Measurement

The Series 251-07 transmitter is meticulously designed to measure pressure differences in both liquids and gases efficiently. Its wet/wet sensor technology allows for reliable operation even with fluids on both sides of the sensor, thereby expanding its range of industrial applications. The device maintains performance across challenging environments, ensuring dependable monitoring for processes requiring accurate pressure data.

Durable Construction for Harsh Environments

Encased in a rugged, powder-coated anodized aluminum body with an IP65 (NEMA 4X) rating, the transmitter withstands dust, moisture, and corrosive elements. Its Viton O-rings provide superior sealing, making it suitable for demanding installations in chemical plants, water treatment facilities, or HVAC systems. This durable design assures long service life and consistent performance, reducing maintenance downtime.

Flexible and Simple Installation

The Sensocon Series 251-07 includes a mounting bracket and features 1/4" NPT female connectors for straightforward integration into existing infrastructure. Electrical connections are handled via a secure terminal block, enabling quick setup. With a broad 12-36 VDC power supply range and compact size, it fits tightly in constrained spaces, supporting both wall and panel mount configurations.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-07:

Q: How do I install the Sensocon Series 251-07 differential pressure transmitter?

A: The transmitter can be wall or panel mounted using the included mounting bracket. Use the 1/4" NPT female connectors for pressure lines and connect the power supply (12-36 VDC) and signal wires to the terminal block. Ensure the device is securely fastened and the O-ring seals are properly seated for reliable performance.Q: What types of media can the Sensocon 251-07 measure?

A: This sensor is compatible with both liquids and gases, making it versatile in various industrial applications such as fluid flow monitoring, filtration, pump control, and process automation where wet/wet differential pressure measurement is required.Q: Where can the transmitter be used considering its environmental ratings?

A: Thanks to its IP65 (NEMA 4X) enclosure and wide temperature operating range (-4F to 185F), the Series 251-07 can be installed in harsh industrial environments including outdoor locations, chemical facilities, plant rooms, or water treatment installations.Q: What is the benefit of the 4-20 mA 2-wire output signal?

A: The 4-20 mA 2-wire output offers long-distance signal transmission with minimized signal loss. This industry-standard output is easy to integrate with existing process control systems and supports diagnostic capabilities for enhanced fault monitoring.Q: When should I use a wet/wet differential pressure transmitter over a dry type?

A: A wet/wet transmitter is preferable when both sides of the sensor will be exposed to fluids, especially in applications involving corrosive or conductive media. This ensures prolonged sensor integrity and measurement reliability.Q: What level of measurement accuracy can I expect from this device?

A: The Sensocon 251-07 delivers a measurement accuracy of 1% full scale, with excellent linearity and minimal hysteresis (0.5% FS), making it suitable for critical industrial process management requiring precise pressure data.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series 251 Wet Differential Pressure Transmitter Category

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Mount Type : Other, Wall or panel mount

Seal Material : Viton standard; others optional

Finishing : Other, Powder coated or anodized finish

Processing Type : Other, Electronic, analog output

Measure Pressure Of : Other, Liquids or gases (wet/wet media)

Sensor Type : Wet/Wet Differential Pressure Transmitter

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Mount Type : Other, Wall mount

Seal Material : Viton Orings

Finishing : Other, Powder Coated

Processing Type : Other, Factory calibrated

Measure Pressure Of : Other, Liquid & Gas (Wet/Wet)

Sensor Type : Wet/Wet Differential Pressure Transmitter

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-01

Mount Type : Other, Wall/Panel Mount

Seal Material : Viton ORings

Finishing : Other, Powder Coated Aluminum Housing

Processing Type : Other, OEM/Factory Calibrated

Measure Pressure Of : Other, Liquids and Gases

Sensor Type : Wet/Wet Differential Pressure Sensor

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Mount Type : Other, Wall Mount

Seal Material : Viton (Standard)

Finishing : Other, Anodized Aluminum

Processing Type : Other, Digital Electronic

Measure Pressure Of : Other, Liquid or Gas

Sensor Type : Wet/Wet Differential Pressure Transmitter

Send Inquiry

Send Inquiry