Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06 Specification

- Seal Material

- Viton standard; others optional

- Bourdon Tube

- Not Applicable (Transmitter type)

- Thread

- 1/4 NPT Female (process connection)

- Sensor Type

- Wet/Wet Differential Pressure Transmitter

- Display

- Digital (optional for monitoring)

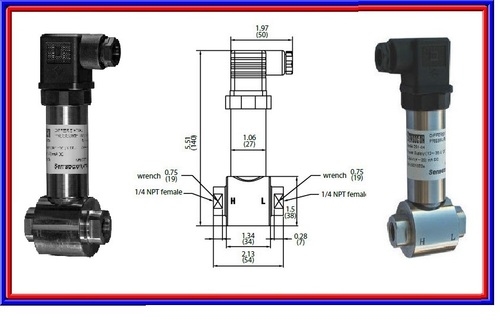

- Outer Size

- Enclosure: 5.12 x 2.36 x 1.9 (approx.)

- Grade

- Industrial Grade

- Material

- Stainless steel process connections; ABS enclosure

- Dial Material

- Not Applicable (no mechanical dial)

- Pointer Material

- Not Applicable (no pointer)

- Processing Type

- Electronic, analog output

- Diameter

- Not Applicable (rectangular enclosure)

- Mount Type

- Wall or panel mount

- Scale Range

- 0-6 psi (differential)

- Accuracy

- 1.0% of full scale

- Finishing

- Powder coated or anodized finish

- Measure Pressure Of

- Liquids or gases (wet/wet media)

- Accessories

- Mounting bracket, electrical connector

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

The Series 251 wet/wet differential pressure transmitter utilizes a double diaphragm sensor technology that outperforms standard double sensor products in accuracy, reliability and static operating pressure. This differential pressure sensing technology offers 0.25% accuracy with static operating pressures up to 1000 PSI. The Series 251 features 316 stainless steel construction designed to meet NEMA 4X (IP 65) standards. The transmitter also offers exceptional field flexibility with a 5:1 turn down and comes standard with a certificate of calibration.

- Media compatibility: Gas and Liquids compatible with 316SS

- Accuracy: +/- 0.25% F.S.

- Over Pressure: positive - 2x f.S.; negative-1x F.S.

- Working Pressure: 1000 PSI (7MPa)

- Temperature Limits: Operating: -40° to 185°F (-40° to 85°C)Compensated: -4° to 158°F (-20° to 70°C)

- Thermal Effect: +/- 0.028% FS/°F (0.050%FS/°C)

- Stability: +/- 0.5% FS/year

- Power Supply: 12-30 VDC

- Output Signal: 4-20 mA, 2-wire

- Electrical Connection: mini DIN 43650

- Response Time: 100 ms

- Turn Down: 5:1

- Enclosure Rating: NEMA 4X (IP 65)

- Process Connection: 1/4" NPT female, optional 1/4" G

- Mounting Position Effect:0.1% F.S., can be corrected by zero adjust

- Model Number : 251-06

- Range:0 - 100 PSI ( 689.5 kPa )

Precision Measurement for Industrial Applications

Series 251-06 is designed to continually monitor differential pressure in wet/wet environmentsideal for process control in HVAC, filtration, and industrial systems. Its 1.0% full-scale accuracy and rapid response time ensure real-time feedback essential for sensitive applications where stability and reliability are critical for system efficiency.

Installation Flexibility and Robust Construction

With wall or panel mount options and an ABS powder-coated or anodized enclosure, the transmitter withstands harsh conditions. Stainless steel process connections and Viton seals provide compatibility with demanding media. External zero and span adjustments enable on-site calibration without disassembly, ensuring efficient setup and maintenance.

Efficient Integration with 4-20 mA Output

The 2-wire, loop-powered 4-20 mA signal ensures seamless connectivity with most industrial automation systems. You can choose an integral cable or terminal block electrical connection, making integration easy and reliable for continuous monitoring and control. Optional digital display aids on-site visual monitoring.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06:

Q: How is the Sensocon Series 251-06 differential pressure transmitter installed?

A: The transmitter can be mounted on walls or panels using the provided bracket and accessories. Its dual 1/4" NPT female pressure ports connect easily to process lines, while electrical connections are made via either integral cable or terminal block.Q: What media can be measured with this wet/wet transmitter?

A: The Series 251-06 is designed to measure differential pressure across wet/wet media, which includes liquids or gases compatible with stainless steel process connections and Viton seals. These materials ensure resilience to a broad range of industrial fluids.Q: When should zero and span adjustments be performed?

A: Zero and span adjustments, accessible via external pots, should be done during initial setup, periodic calibration, or after maintenance to maintain accurate readings and compensate for drift or installation effects.Q: Where is the transmitter typically used?

A: This transmitter is used wherever precise differential pressure monitoring is neededsuch as in HVAC systems, industrial filtration, pump monitoring, and process control applications, especially those involving wet media.Q: What benefits does the optional digital display provide?

A: The optional digital display allows operators to visually monitor real-time differential pressure values onsite, which simplifies troubleshooting and ensures quick verification of system performance.Q: How does the transmitter handle overpressure conditions?

A: The transmitter is engineered to withstand up to three times its rated pressure range, protecting it from occasional spikes and prolonging service life in demanding process environments.Q: What is the process for connecting the transmitter to a control system?

A: Connect the devices 4-20 mA output to a compatible data acquisition or automation system, ensuring the 12-30 VDC power supply and proper wiring to terminal block or integral cable. This setup enables continuous electronic monitoring and control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series 251 Wet Differential Pressure Transmitter Category

Sensocon USA Series 251 - Wet/Wet Differential Pressure Transmitter

Sensor Type : Wet/Wet Differential Pressure Transmitter

Outer Size : Compact Body

Display : None (Transmitter Output)

Grade : Industrial

Processing Type : Other, Analog Output

Accessories : Mounting Hardware Included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Sensor Type : Wet/Wet Differential Pressure Transmitter

Outer Size : Approx. 117mm x 56mm x 155mm

Display : None (Transmitter Only)

Grade : Industrial

Processing Type : Other, Digital Electronic

Accessories : Mounting hardware included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Sensor Type : Wet/Wet Differential Pressure Transmitter

Outer Size : 126 mm x 83 mm x 60 mm (Approx.)

Display : Analog (Optional LCD Digital)

Grade : Industrial

Processing Type : Other, Factory calibrated

Accessories : Mounting kit included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-01

Sensor Type : Wet/Wet Differential Pressure Sensor

Outer Size : See datasheet for dimensions

Display : None (Output Signal Only)

Grade : Industrial

Processing Type : Other, OEM/Factory Calibrated

Accessories : Mounting hardware included

Send Inquiry

Send Inquiry