Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05 Specification

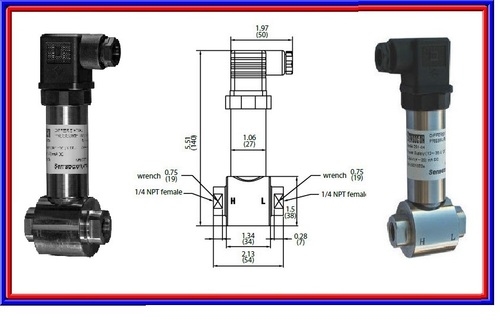

- Outer Size

- 126 mm x 83 mm x 60 mm (Approx.)

- Sensor Type

- Wet/Wet Differential Pressure Transmitter

- Seal Material

- Viton O-rings

- Display

- Analog (Optional LCD Digital)

- Thread

- 1/4 NPT Female

- Grade

- Industrial

- Material

- Aluminum housing, Stainless Steel wetted parts

- Processing Type

- Factory calibrated

- Diameter

- 126 mm (Body Width)

- Mount Type

- Wall mount

- Scale Range

- 0 5 psi (Other ranges available)

- Accuracy

- 0.5% FS (Full Scale)

- Finishing

- Powder Coated

- Measure Pressure Of

- Liquid & Gas (Wet/Wet)

- Accessories

- Mounting kit included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05The Series 251 wet/wet differential pressure transmitter utilizes a double diaphragm sensor technology that outperforms standard double sensor products in accuracy, reliability and static operating pressure. This differential pressure sensing technology offers 0.25% accuracy with static operating pressures up to 1000 PSI. The Series 251 features 316 stainless steel construction designed to meet NEMA 4X (IP 65) standards. The transmitter also offers exceptional field flexibility with a 5:1 turn down and comes standard with a certificate of calibration.

- Media compatibility: Gas and Liquids compatible with 316SS

- Accuracy: +/- 0.25% F.S.

- Over Pressure: positive - 2x f.S.; negative-1x F.S.

- Working Pressure: 1000 PSI (7MPa)

- Temperature Limits: Operating: -40° to 185°F (-40° to 85°C)Compensated: -4° to 158°F (-20° to 70°C)

- Thermal Effect: +/- 0.028% FS/°F (0.050%FS/°C)

- Stability: +/- 0.5% FS/year

- Power Supply: 12-30 VDC

- Output Signal: 4-20 mA, 2-wire

- Electrical Connection: mini DIN 43650

- Response Time: 100 ms

- Turn Down: 5:1

- Enclosure Rating: NEMA 4X (IP 65)

- Process Connection: 1/4" NPT female, optional 1/4" G

- Mounting Position Effect:0.1% F.S., can be corrected by zero adjust

- Model Number : 251-05

- Range: 0 - 50 PSI ( 344.7 kPa )

Versatile Measurement Capabilities

Engineered for both liquid and gas pressure applications, the Series 251-05 transmitter excels in environments where reliable wet/wet differential pressure readings are essential. Its durable stainless steel wetted parts and wide range of output options allow seamless integration with most industrial systems.

Industrial-Grade Construction

With an IP65 ingress protection rating and robust aluminum housing, this transmitter is built for long-term, uninterrupted service in challenging conditions. The powder-coated exterior, Viton O-ring seals, and stainless steel components ensure resilience against harsh chemicals and temperature extremes.

Precision and Easy Installation

Factory calibrated to deliver 0.5% full-scale accuracy, the Series 251-05 ensures dependable pressure monitoring. Mounting is straightforward with included hardware, and the compact size fits easily within control panels or process lines, making setup efficient for users.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05:

Q: How do I install the Sensocon 251-05 transmitter for wall mounting?

A: The transmitter includes a mounting kit that facilitates secure attachment to any flat wall surface. To install, use the provided hardware to fix the unit with its ports accessible for pipe connections, ensuring the 1/4" NPT female threads are properly aligned and sealed.Q: What makes the Series 251-05 suitable for both liquid and gas differential pressure measurement?

A: Thanks to its wet/wet design with stainless steel wetted parts and Viton O-rings, the Series 251-05 efficiently measures pressure differences in systems carrying liquids, gases, or both, ensuring compatibility with a wide range of industrial media.Q: When should I use the internal zero and span adjustment feature?

A: The internal zero and span adjustment is recommended when calibrating the transmitter to match your specific system requirements or after installation, ensuring continued precision over the devices operational lifespan.Q: Where can the Sensocon 251-05 be used given its temperature and protection ratings?

A: With a temperature range from -20C to +85C and IP65 ingress protection, the transmitter is suitable for both indoor and outdoor industrial locations where exposure to dust, splashes, or mild weather conditions is expected.Q: What electrical output options are available and how do they benefit integration?

A: The Series 251-05 offers a standard 420 mA output, with optional 05V or 010V outputs. This versatility allows easy connection to most industrial controllers and data acquisition systems, enhancing integration flexibility.Q: How quickly does the Series 251-05 respond to pressure changes?

A: With a response time of less than 5 milliseconds, the transmitter delivers rapid, real-time pressure data, which is critical for dynamic process control and monitoring applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series 251 Wet Differential Pressure Transmitter Category

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Measure Pressure Of : Other, Liquids or gases (wet/wet media)

Outer Size : Enclosure: 5.12 x 2.36 x 1.9 (approx.)

Accuracy : 1.0% of full scale

Accessories : Mounting bracket, electrical connector

Processing Type : Other, Electronic, analog output

Scale Range : 06 psi (differential)

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Measure Pressure Of : Other, Liquid or Gas

Outer Size : Approx. 117mm x 56mm x 155mm

Accuracy : 1% FS

Accessories : Mounting hardware included

Processing Type : Other, Digital Electronic

Scale Range : 03 PSI (Standard)

Sensocon USA Series 251 - Wet/Wet Differential Pressure Transmitter

Measure Pressure Of : Other, Liquids and Gases

Outer Size : Compact Body

Accuracy : 0.5% of Full Scale

Accessories : Mounting Hardware Included

Processing Type : Other, Analog Output

Scale Range : 0 to 250 PSI Differential

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-02

Measure Pressure Of : Other, Liquids and Gases (Wet/Wet applications)

Outer Size : 92 mm (approximate body diameter)

Accuracy : 1% of Full Scale

Accessories : Mounting Bracket, Instruction Manual

Processing Type : Other, SolidState Electronic

Scale Range : 0 to 250 inWC (other ranges available on request)

Send Inquiry

Send Inquiry