Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-02

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-02 Specification

- Grade

- Industrial

- Thread

- 1/4 NPT Female

- Display

- None (4-20 mA output)

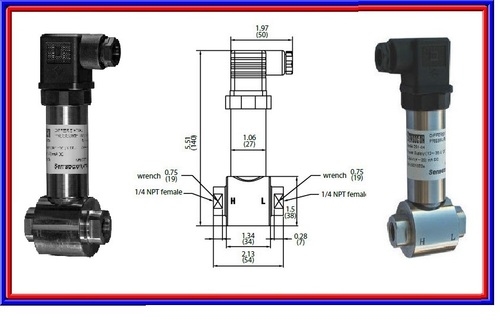

- Outer Size

- 92 mm (approximate body diameter)

- Sensor Type

- Wet/Wet Differential Pressure Transmitter

- Seal Material

- Viton

- Material

- Anodized Aluminum, 316L Stainless Steel Wetted Parts

- Processing Type

- Solid-State Electronic

- Diameter

- 92 mm (approx.)

- Mount Type

- Wall or Surface Mount

- Scale Range

- 0 to 250 inWC (other ranges available on request)

- Accuracy

- 1% of Full Scale

- Finishing

- Anodized Aluminum Housing

- Measure Pressure Of

- Liquids and Gases (Wet/Wet applications)

- Accessories

- Mounting Bracket, Instruction Manual

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-02 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-02

The Series 251 wet/wet differential pressure transmitter utilizes a double diaphragm sensor technology that outperforms standard double sensor products in accuracy, reliability and static operating pressure. This differential pressure sensing technology offers 0.25% accuracy with static operating pressures up to 1000 PSI. The Series 251 features 316 stainless steel construction designed to meet NEMA 4X (IP 65) standards. The transmitter also offers exceptional field flexibility with a 5:1 turn down and comes standard with a certificate of calibration.

- Media compatibility: Gas and Liquids compatible with 316SS

- Accuracy: +/- 0.25% F.S.

- Over Pressure: positive - 2x f.S.; negative-1x F.S.

- Working Pressure: 1000 PSI (7MPa)

- Temperature Limits: Operating: -40° to 185°F (-40° to 85°C)Compensated: -4° to 158°F (-20° to 70°C)

- Thermal Effect: +/- 0.028% FS/°F (0.050%FS/°C)

- Stability: +/- 0.5% FS/year

- Power Supply: 12-30 VDC

- Output Signal: 4-20 mA, 2-wire

- Electrical Connetction: mini DIN 43650

- Response Time: 100 ms

- Turn Down: 5:1

- Enclosure Rating: NEMA 4X (IP 65)

- Process Connection: 1/4" NPT female, optional 1/4" G

- Mounting Position Effect:

- 0.1% F.S., can be corrected by zero adjust

- Model Number : 251-02

- Range : 0 - 10 PSI ( 68.9 kPa )

Versatile Differential Pressure Measurement

Designed for wet/wet applications, the Series 251-02 accurately measures differential pressures in both liquid and gas systems. With a maximum static line pressure of 500 psi (34.5 bar) and accuracy within 1% of full scale, it ensures reliable data even in demanding industrial processes.

Robust Construction and Environmental Protection

The transmitter features a rugged anodized aluminum housing and 316L stainless steel wetted parts, making it corrosion-resistant and durable. It is housed within a NEMA 4X (IP65)-rated enclosure, ensuring it operates dependably in harsh environments, including those prone to moisture and dust.

Easy Installation and Low Maintenance

Equipped with 1/4" NPT female threads and a wall/surface mounting bracket, installation is straightforward. The external push buttons for zero and span adjustments allow for hassle-free calibration and tuning, minimizing downtime and simplifying maintenance for operators.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-02:

Q: How does the Series 251-02 transmitter measure differential pressure in wet/wet applications?

A: The Series 251-02 uses solid-state electronic sensors to evaluate pressure differences between two wet media points, enabling the monitoring of liquids or gases in industrial piping or HVAC systems.Q: What are the primary benefits of using the 251-02 differential pressure transmitter?

A: Key advantages include high accuracy (1% of full scale), robust anodized aluminum and 316L stainless steel construction, NEMA 4X (IP65) environmental protection, and quick adjustments for zero and span, making it ideal for industrial and HVAC monitoring tasks.Q: When should this transmitter be selected for a process control application?

A: Choose the Series 251-02 when you need to monitor the differential pressure of two wetted process lines, especially in systems where both sides may contain liquid or gas under pressure, and reliability and accuracy are crucial.Q: Where can the Series 251-02 be installed and what mounting options are available?

A: This transmitter can be wall- or surface-mounted using the included bracket. Its compact, cylindrical design and durable enclosure suit both indoor and outdoor industrial or commercial locations.Q: What is the process for zero and span adjustment on this device?

A: Zero and span can be adjusted externally via conveniently located push buttons. This feature allows operators to calibrate the transmitter quickly without dismantling or removing it from service.Q: How is the electrical output configured for integration with monitoring systems?

A: The device outputs a standard 4-20 mA signal (2-wire), making it compatible with most industrial control and data acquisition systems. It requires a 12-36 VDC power supply.Q: What types of media can the 251-02 measure and what materials are in contact with process fluids?

A: Its suitable for both liquids and gases in wet/wet applications. Media-contacted parts are made of 316L stainless steel and Viton, ensuring resistance to corrosion and chemical compatibility in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series 251 Wet Differential Pressure Transmitter Category

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Processing Type : Other, Digital Electronic

Sensor Type : Wet/Wet Differential Pressure Transmitter

Outer Size : Approx. 117mm x 56mm x 155mm

Measure Pressure Of : Other, Liquid or Gas

Accuracy : 1% FS

Seal Material : Viton (Standard)

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Processing Type : Other, Factory calibrated

Sensor Type : Wet/Wet Differential Pressure Transmitter

Outer Size : 126 mm x 83 mm x 60 mm (Approx.)

Measure Pressure Of : Other, Liquid & Gas (Wet/Wet)

Accuracy : 0.5% FS (Full Scale)

Seal Material : Viton Orings

Sensocon USA Series 251 - Wet/Wet Differential Pressure Transmitter

Processing Type : Other, Analog Output

Sensor Type : Wet/Wet Differential Pressure Transmitter

Outer Size : Compact Body

Measure Pressure Of : Other, Liquids and Gases

Accuracy : 0.5% of Full Scale

Seal Material : BunaN

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-07

Processing Type : Other, Electronic/Signal Processing

Sensor Type : Wet/Wet Differential Pressure Sensor

Outer Size : Approximately 120mm x 80mm x 55mm

Measure Pressure Of : Other, Liquids and Gases

Accuracy : 1% Full Scale

Seal Material : Viton Orings

Send Inquiry

Send Inquiry