Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03 Specification

- Thread

- 1/4 NPT Female

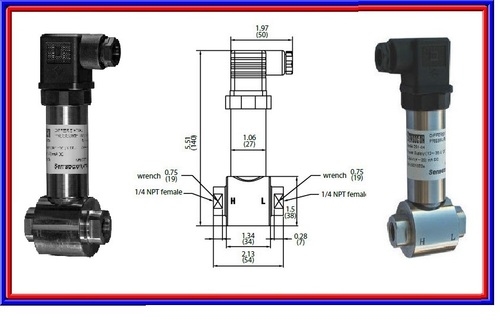

- Outer Size

- Approx. 117mm x 56mm x 155mm

- Seal Material

- Viton (Standard)

- Sensor Type

- Wet/Wet Differential Pressure Transmitter

- Grade

- Industrial

- Display

- None (Transmitter Only)

- Material

- Aluminum Body, Stainless Steel Wetted Parts

- Processing Type

- Digital Electronic

- Diameter

- Body Width approx. 56mm

- Mount Type

- Wall Mount

- Scale Range

- 0-3 PSI (Standard)

- Accuracy

- 1% FS

- Finishing

- Anodized Aluminum

- Measure Pressure Of

- Liquid or Gas

- Accessories

- Mounting hardware included

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03 Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03

The Series 251 wet/wet differential pressure transmitter utilizes a double diaphragm sensor technology that outperforms standard double sensor products in accuracy, reliability and static operating pressure. This differential pressure sensing technology offers 0.25% accuracy with static operating pressures up to 1000 PSI. The Series 251 features 316 stainless steel construction designed to meet NEMA 4X (IP 65) standards. The transmitter also offers exceptional field flexibility with a 5:1 turn down and comes standard with a certificate of calibration.

- Media compatibility: Gas and Liquids compatible with 316SS

- Accuracy: +/- 0.25% F.S.

- Over Pressure: positive - 2x f.S.; negative-1x F.S.

- Working Pressure: 1000 PSI (7MPa)

- Temperature Limits: Operating: -40° to 185°F (-40° to 85°C)Compensated: -4° to 158°F (-20° to 70°C)

- Thermal Effect: +/- 0.028% FS/°F (0.050%FS/°C)

- Stability: +/- 0.5% FS/year

- Power Supply: 12-30 VDC

- Output Signal: 4-20 mA, 2-wire

- Electrical Connection: mini DIN 43650

- Response Time: 100 ms

- Turn Down: 5:1

- Enclosure Rating: NEMA 4X (IP 65)

- Process Connection: 1/4" NPT female, optional 1/4" G

- Mounting Position Effect:0.1% F.S., can be corrected by zero adjust

- Model Number : 251-03

- Range : 0 - 15 PSI ( 103 kPa )

Versatile Differential Pressure Measurement

Designed to support both liquid and gas media, the Series 251-03 ensures flexibility in various process control and monitoring systems. Its wet/wet configuration makes it ideal for applications where both ports are exposed to fluid media, maximizing compatibility and stability for industrial-grade performance.

Reliable Performance and Intelligent Design

With a rugged anodized aluminum body and stainless steel wetted parts, this transmitter withstands harsh environments and resists corrosion. The integrated Viton seal and NEMA 4 (IP65) rating offer additional protection from moisture and dust, ensuring long-lasting operation in indoor or outdoor locations.

User-Friendly Installation and Calibration

This transmitter is supplied with mounting hardware and utilizes a 1/4" NPT female thread for quick connection. Electrical setup is streamlined by a terminal block and cable gland. Internal potentiometers provide simple zero and span calibrations, allowing users to adapt the device for precise process requirements.

FAQs of Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-03:

Q: How is the Sensocon Series 251-03 differential pressure transmitter installed and connected?

A: The transmitter is wall-mounted using the included hardware and connects via a 1/4" NPT female thread. Electrical wiring is straightforward with a terminal block and cable gland, requiring a 1230 VDC power supply.Q: What types of media are compatible with the Series 251-03 transmitter?

A: This device is suitable for most liquids and gases that are not corrosive to its stainless steel wetted parts and Viton seal, making it highly versatile across various industrial applications.Q: When should I consider adjusting the zero and span settings?

A: You should adjust zero and span via the internal potentiometers when setting up the transmitter for your specific process conditions or if you notice drift in measured values, ensuring ongoing measurement accuracy.Q: Where can the Series 251-03 transmitter be effectively used?

A: Thanks to its IP65/NEMA 4 protection rating, this transmitter can be reliably operated in both indoor and harsh outdoor environments, including process plants, HVAC systems, and fluid handling installations.Q: What benefits does the digital electronic processing type provide?

A: The digital electronic processing ensures rapid response times (<100 ms), higher measurement stability, and improved accuracy, enhancing real-time control and monitoring in critical industrial processes.Q: How do I calibrate the Series 251-03 transmitter for my application?

A: Calibration involves accessing the internal potentiometers to fine-tune zero and span. This enables precise adjustments to match the actual operating conditions and the requirements of your monitoring system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series 251 Wet Differential Pressure Transmitter Category

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-06

Scale Range : 06 psi (differential)

Grade : Industrial Grade

Seal Material : Viton standard; others optional

Sensor Type : Wet/Wet Differential Pressure Transmitter

Measure Pressure Of : Other, Liquids or gases (wet/wet media)

Thread : 1/4 NPT Female (process connection)

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-05

Scale Range : 0 5 psi (Other ranges available)

Grade : Industrial

Seal Material : Viton Orings

Sensor Type : Wet/Wet Differential Pressure Transmitter

Measure Pressure Of : Other, Liquid & Gas (Wet/Wet)

Thread : 1/4 NPT Female

Sensocon USA Series 251 - Wet/Wet Differential Pressure Transmitter

Scale Range : 0 to 250 PSI Differential

Grade : Industrial

Seal Material : BunaN

Sensor Type : Wet/Wet Differential Pressure Transmitter

Measure Pressure Of : Other, Liquids and Gases

Thread : 1/4 NPT

Sensocon USA Wet/Wet Differential Pressure Transmitter Series 251-01

Scale Range : 04000 PSI (Varies by model)

Grade : Industrial

Seal Material : Viton ORings

Sensor Type : Wet/Wet Differential Pressure Sensor

Measure Pressure Of : Other, Liquids and Gases

Thread : 1/4 NPT Female

Send Inquiry

Send Inquiry