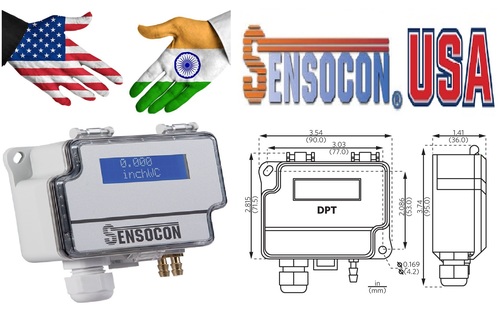

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -125 - 125 Pa

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -125 - 125 Pa Specification

- Thread

- Rear Mounting with Pressure Ports

- Outer Size

- 80 mm x 60 mm x 36 mm (Approx)

- Seal Material

- Silicone

- Sensor Type

- Capacitive Differential Pressure Sensor

- Grade

- Industrial

- Display

- No Local Display

- Material

- ABS Plastic Housing

- Processing Type

- Electronic

- Mount Type

- Panel/Wall Mount

- Scale Range

- -125 to 125 Pa

- Accuracy

- 1% of Full Scale

- Finishing

- Matte Grey Housing

- Measure Pressure Of

- Air, Non-corrosive Gases

- Accessories

- Mounting Screws, Rubber Gasket

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -125 - 125 Pa Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -125 - 125 Pa

Key Features of the DPT10-R8

The DPT10-R8 boasts a capacitive differential pressure sensor that delivers high measurement accuracy (1% of full scale) across a range ideal for HVAC and filter monitoring. Its selectable analog outputs, fast response time, and protective IP54 enclosure ensure reliable performance even in demanding environments. Easy mounting via included screws and gasket means quick setup for both wall and panel installations.

Effortless Installation and Operation

With intuitive screw terminal connections and dual barbed pressure fittings, the DPT10-R8 supports straightforward installation. The front-panel zero-point adjustment button enables quick calibration without dismantling the housing, while the included accessoriesmounting screws and rubber gasketensure secure and leak-free setup in a variety of settings.

Reliable Monitoring for Industrial Applications

Engineered for industrial use, the DPT10-R8 excels in monitoring air and non-corrosive gas pressure in ventilation systems, cleanrooms, and controlled environments. Its solid-state electronics and durable ABS enclosure provide resilience and stability, making it a trusted solution for maintaining optimal process control and ensuring compliance with operational standards.

FAQs of Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -125 - 125 Pa:

Q: How can I install the Sensocon DPT10-R8 differential pressure transmitter?

A: The DPT10-R8 can be mounted on a panel or wall using the included mounting screws and rubber gasket. Its rear pressure ports accept 1/8" ID tubing via dual barbed fittings. Electrical connections are made through screw terminals, making setup quick and straightforward.Q: What types of media can I measure with this transmitter?

A: This device is suitable for measuring the differential pressure of air or non-corrosive gases only. Using it with corrosive gases or liquids could damage the sensor and affect its accuracy.Q: When should the zero-point adjustment be performed?

A: Zero-point adjustment is recommended during initial installation or whenever calibration accuracy is questioned. The dedicated front panel button allows for easy zeroing without disassembling the unit.Q: Where is the transmitter typically used?

A: The DPT10-R8 is widely utilized in industrial and commercial applications such as HVAC systems, filter monitoring, cleanrooms, and environments requiring precise air pressure measurement and control.Q: What are the selectable output signals and how are they used?

A: The unit provides both 4-20 mA and 0-10 V output signals, selectable based on system requirements. These outputs ensure compatibility with most industrial monitoring and control equipment.Q: How does the transmitter benefit system operation?

A: By providing real-time, accurate pressure data with a rapid response time of less than one second, the DPT10-R8 aids in maintaining optimal conditions, improving system efficiency, and facilitating preventive maintenance.Q: What are the environmental and safety protection features?

A: The DPT10-R8 features an IP54 enclosure, ensuring resistance to dust and water splashes, while its matte grey ABS plastic housing and silicone seals add durability for long-term industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series DPT Differential Pressure Transmitter India Category

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -12.5 - 12.5 mbar

Processing Type : Other, Electronic

Accessories : Mounting Kit Included

Finishing : Other, Anodized Aluminum / ABS Plastic

Accuracy : 1% of span

Mount Type : Other, Wall/Surface Mount

Grade : Industrial

Sensocon USA Differential Pressure Transmitter Series DPT30-R8 - Range -254 - 254 mmWC

Processing Type : Other, Electronic

Accessories : Mounting Kit, User Manual

Finishing : Other, IP65 Enclosure, Polycarbonate Housing

Accuracy : 1% of Full Scale

Mount Type : Other, Wall Mount

Grade : Industrial

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range 0 - 250 Pa

Processing Type : Other, Electronic

Accessories : Mounting screws and instruction manual

Finishing : Other, Matte Grey Plastic Housing

Accuracy : 1.5% FS

Mount Type : Other, Wall Mount

Grade : Industrial

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range 0 - 2.5 inWC

Processing Type : Other, Electronic

Accessories : Mounting screws included

Finishing : Other, Polycarbonate Enclosure

Accuracy : 1% of Full Scale

Mount Type : Other, Wall Mount

Grade : Industrial

Send Inquiry

Send Inquiry