Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -12.5 - 12.5 mbar

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -12.5 - 12.5 mbar Specification

- Seal Material

- Silicone

- Sensor Type

- Differential Pressure Transmitter

- Thread

- 1/8 NPT Female

- Outer Size

- Compact Housing

- Display

- LED Digital Display

- Grade

- Industrial

- Material

- Aluminum / Plastic

- Processing Type

- Electronic

- Diameter

- 80 mm (Front Plate)

- Mount Type

- Wall/Surface Mount

- Scale Range

- -12.5 to 12.5 mbar

- Accuracy

- 1% of span

- Finishing

- Anodized Aluminum / ABS Plastic

- Measure Pressure Of

- Air and Non-combustible Gases

- Accessories

- Mounting Kit Included

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -12.5 - 12.5 mbar Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- North America, South America, Eastern Europe, Middle East, Western Europe, Africa, Central America, Asia, Australia

- Main Domestic Market

- All India

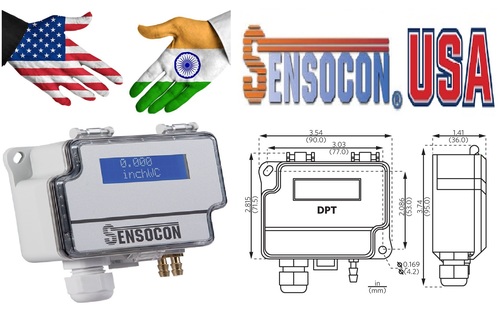

About Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -12.5 - 12.5 mbar

Precise Differential Pressure Measurement

Designed specifically for air and non-combustible gases, the DPT10-R8 delivers reliable differential pressure readings ranging from -12.5 to 12.5 mbar. Its fast response time, electronic processing, and LED digital display ensure real-time monitoring crucial for industrial and HVAC settings.

Rugged and Versatile Construction

Encased in anodized aluminum and ABS plastic, this transmitter can withstand harsh environments and overpressure up to 150 mbar. The IP54 protection rating and silicone seal make the device suitable for cleanrooms, HVAC systems, and filter monitoring, while maintaining long-term durability.

Effortless Adjustment and Installation

Featuring front-panel zero and span adjustment, the DPT10-R8 allows quick on-site calibration. Its compact housing (80 mm diameter front plate), screw terminal electrical connection, wall/surface mount design, and included mounting kit ensure straightforward installation and integration into existing systems.

FAQs of Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range -12.5 - 12.5 mbar:

Q: How can I install the Sensocon DPT10-R8 Differential Pressure Transmitter in my HVAC system?

A: The DPT10-R8 can be surface or wall-mounted using the included mounting kit. Electrical connection is made through screw terminal blocks, and the transmitter is powered by a 24V DC supply. Simply connect the 1/8 NPT female threaded process ports to your air ducts or filter lines.Q: What types of applications is the DPT10-R8 suitable for?

A: This differential pressure transmitter is ideal for HVAC applications, cleanroom pressure control, and filter monitoring. It measures air and other non-combustible gases, providing precise monitoring for industrial-grade environments.Q: When should I adjust the zero and span settings on this transmitter?

A: Zero and span adjustment is typically required during initial installation, after maintenance, or if there are noticeable drifts in the pressure readings. Adjustments are easily accessible via the front panel for on-site calibration.Q: Where are the adjustment controls and electrical connections located on the device?

A: Zero and span adjustment controls are situated on the front panel, allowing access without removing the transmitter from its mount. Electrical connections are made through the screw terminal blocks positioned at the back or side of the housing.Q: What is the process for calibrating the transmitter for optimal accuracy?

A: To calibrate, apply known reference pressures at the process ports and use the front-panel controls to adjust zero and span until the LED display matches the applied values. This ensures the transmitter operates within its specified 1% accuracy range.Q: How does using this transmitter benefit my air monitoring systems?

A: By offering fast response times (less than 1 second), high accuracy, and real-time digital readouts, the DPT10-R8 enhances system performance, helps optimize energy consumption, and maintains air quality standards in your facility.Q: What should I do if the transmitter is exposed to pressures above its rated range?

A: The DPT10-R8 is designed to withstand up to 150 mbar overpressure briefly without damage, but repeated overpressure should be avoided to preserve sensor accuracy and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series DPT Differential Pressure Transmitter India Category

Sensocon USA Differential Pressure Transmitter Series DPT10-R8 - Range 0 - 12.5 mbar

Finishing : Other, Matte/Plastic Housing

Scale Range : 0 12.5 mbar

Material : Other, ABS Plastic Housing

Grade : Industrial

Processing Type : Other, Electronic

Accessories : Mounting Screws, Instruction Manual

Sensocon USA Differential Pressure Transmitter Series DPT30-R8 - Range 0 - 762 mmWC

Finishing : Other, ABS Plastic Housing

Scale Range : 0 762 mmWC

Material : Other, ABS Plastic

Grade : Industrial

Processing Type : Other, Electronic

Accessories : Mounting screws, Pressure ports, User manual

Sensocon USA Differential Pressure Transmitter Series DPT30-R8 - Range -380 - 380 mmWC

Finishing : Other, Powder Coated

Scale Range : 380 to 380 mmWC

Material : Other, ABS Plastic Enclosure

Grade : Industrial

Processing Type : Other, Solid State Electronics

Accessories : Mounting Hardware, Instruction Manual

Sensocon USA Series DPT1-R8 - Range -0.5 - .05 in WC

Finishing : Other, Matte ABS Casing

Scale Range : 0.5 to 0.05 in WC

Material : Other, ABS Plastic Enclosure

Grade : Industrial

Processing Type : Other, Microprocessor Controlled

Accessories : Mounting Screws, Manual

Send Inquiry

Send Inquiry