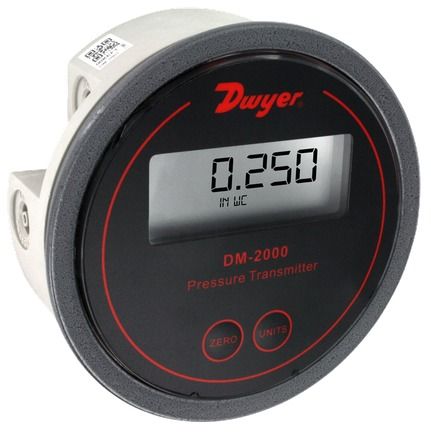

Dwyer DM-2012-LCD PRESSURE TRANSMITTER

Dwyer DM-2012-LCD PRESSURE TRANSMITTER Specification

- Display

- LCD Digital Display

- Grade

- Industrial Grade

- Outer Size

- Approx. 89 x 64 x 36 mm

- Thread

- 1/8 NPT Male

- Sensor Type

- Piezo-resistive Silicon Sensor

- Seal Material

- Buna-N

- Material

- ABS Plastic Housing

- Dial Material

- Not Applicable (LCD Display)

- Pointer Material

- Not Applicable (Digital)

- Processing Type

- Microprocessor Based

- Diameter

- 64 mm approx. (body width)

- Glass Size

- Not Applicable (LCD Screen)

- Mount Type

- Panel Mount or Surface Mount

- Scale Range

- -1000 to +1000 Pa (Pascal)

- Accuracy

- 1% of Full Scale

- Finishing

- Powder Coated / Matt Finish

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting Screws, User Manual

Dwyer DM-2012-LCD PRESSURE TRANSMITTER Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Middle East, Western Europe, Africa, Central America, Eastern Europe, South America, Asia, North America, Australia

About Dwyer DM-2012-LCD PRESSURE TRANSMITTER

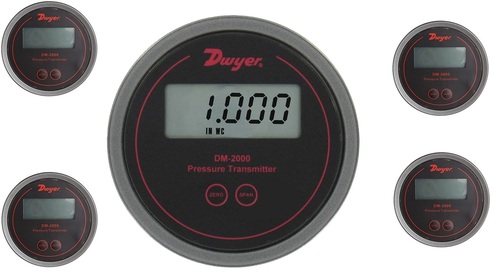

Dwyer DM-2012-LCD PRESSURE TRANSMITTER

A wide range of models are available factory calibrated to specific ranges Pressure connections are inherent to the glass filled plastic molded housing making installation quick and easyDigital push-button zero and span simplify calibration over typical turn-potentiometers An optional 3.5 digit LCD shows process and engineering units A single bush button allows field selection of 4 to 6 engineering units depending on range on LCD models

Specifications

- Service: Air and non-combustible, compatible gases.

- Wetted Materials: Consult Factory.

- Accuracy: ±1% F.S. at 70°F.

- Stability: +1% F.S./yr.

- Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

- Pressure Limits: 10 psig (0.69 bar).

- Thermal Effect: ±0.055% F.S./°F (0.099% F.S./°C).

- Power Requirements: 10-35 VDC (2 wire).

- Output Signal: 4 to 20 mA.

- Zero and Span Adjustments: Digital push-button zero and span.

- Loop Resistance: DC: 0-1250 ohms maximum.

- Current Consumption: DC: 38 mA maximum.

- Electrical Connections: Screw-type terminal block.

- Display: 3.5 digit LCD, 0.7" height.

- Process Connections: 1/8" I.D. tubing.

- Mounting Orientation: Vertical.

- Weight: 4.8 oz (136 g).

Model

DM-2012-LCD

Description

Differential pressure transmitter, range .250-0-.250" w.c., 62.2-0-62.2 Pa, 6.35-0-6.35 mm w.c., .622-0-.622 mbar.

Versatile Output and Easy Installation

The DM-2012-LCD transmitter features selectable output options (4-20 mA or 0-10 VDC) to suit a range of control systems. With screw terminal electrical connections and panel or surface mount options, installation is streamlined for building automation and industrial applications. Included mounting screws and a user manual ensure a smooth setup process.

Robust Design with User-Friendly Interface

Engineered for durability, the device offers IP54 protection, a powder-coated ABS plastic housing, and operates reliably across a wide temperature range. Its front-panel-accessible zero and span adjustments and clear LCD digital display allow precise calibration and effortless readings, making it ideal for HVAC and clean room monitoring.

FAQs of Dwyer DM-2012-LCD PRESSURE TRANSMITTER:

Q: How do I select between the 4-20 mA and 0-10 VDC output signals on the Dwyer DM-2012-LCD?

A: Output selection on the DM-2012-LCD is easily achieved by configuring the built-in jumper settings according to the user manual instructions. This allows you to adapt the transmitter for compatibility with your existing control system requirements.Q: What type of environments is the DM-2012-LCD pressure transmitter suitable for?

A: This device is engineered for industrial applications, including building automation, HVAC systems, and clean room monitoring. It is designed to measure differential pressure of air and non-corrosive gases within the specified scale range and operates reliably in demanding indoor environments.Q: When should I use the zero and span adjustment features located on the front panel?

A: Zero and span adjustments are used during initial setup or calibration to ensure accurate readings across the full pressure scale. Accessing these controls from the front panel simplifies routine calibration or adjustments after installation.Q: Where should the DM-2012-LCD transmitter be installed for optimal performance?

A: Ideally, install the transmitter in a location where it can accurately sample the process air or gas and where ambient conditions fall within the 0C to +50C operating range. The device can be panel or surface mounted, as required, and mounting accessories are provided for secure installation.Q: What benefits does the LCD digital display offer for pressure monitoring?

A: The integrated LCD display delivers clear, real-time pressure readings, reducing operator error and facilitating quick status checks. This feature improves usability and accuracy, especially in environments requiring continuous monitoring, such as clean rooms and HVAC systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer Differential Pressure Transmitter Wholesale Category

Dwyer DM-2006-LCD PRESSURE TRANSMITTER

Mount Type : Other, Panel Mount

Finishing : Other, Powdercoated

Seal Material : Nitrile Rubber

Sensor Type : Pressure Sensor

Accessories : Mounting bracket included

Material : Other, ABS Plastic Housing

Dwyer DM-2019-LCD PRESSURE TRANSMITTER

Mount Type : Other, Panel Mount / Surface Mount

Finishing : Matte

Seal Material : Neoprene

Sensor Type : Pressure Sensor

Accessories : Mounting Screws, LCD Display

Material : Other, ABS Plastic Housing

Dwyer DM-2002-LCD Differential Pressure Transmitter

Mount Type : Other, Wall Mount

Finishing : Other, Powder Coated

Seal Material : Silicone

Sensor Type : Differential Pressure Sensor

Accessories : Mounting hardware included

Material : Other, Polycarbonate Housing

Dwyer DM-2004-LCD PRESSURE TRANSMITTER

Mount Type : Other, Wall Mount or Surface Mount

Finishing : Other, Powder Coated

Seal Material : Silicone

Sensor Type : Differential Pressure Sensor

Accessories : Mounting Hardware, User Manual

Material : Other, ABS Plastic Housing

Send Inquiry

Send Inquiry