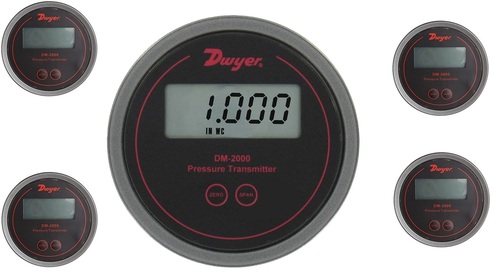

Dwyer DM-2006-LCD PRESSURE TRANSMITTER

Dwyer DM-2006-LCD PRESSURE TRANSMITTER Specification

- Grade

- Industrial

- Thread

- 1/4 NPT male

- Sensor Type

- Pressure Sensor

- Outer Size

- 96 x 96 mm

- Display

- LCD Digital

- Seal Material

- Nitrile Rubber

- Material

- ABS Plastic Housing

- Dial Material

- Polycarbonate

- Processing Type

- Digital Measurement

- Diameter

- 96 mm

- Glass Size

- 96 x 96 mm

- Mount Type

- Panel Mount

- Scale Range

- 0 to 250 Pa

- Accuracy

- 1% full scale

- Finishing

- Powder-coated

- Measure Pressure Of

- Air and Non-corrosive gases

- Accessories

- Mounting bracket included

Dwyer DM-2006-LCD PRESSURE TRANSMITTER Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Africa, Central America, Eastern Europe, Asia, North America

- Main Domestic Market

- All India

About Dwyer DM-2006-LCD PRESSURE TRANSMITTER

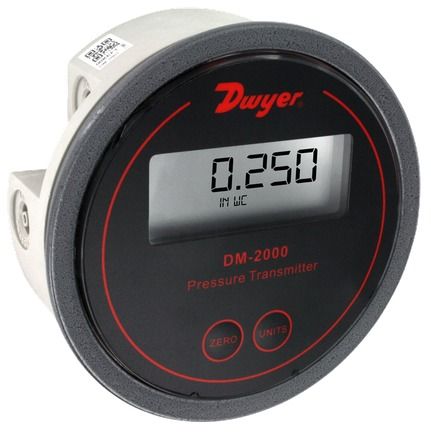

Dwyer DM-2006-LCD PRESSURE TRANSMITTER

- A wide range of models are available factory calibrated to specific ranges=

- Pressure connections are inherent to the glass filled plastic molded housing making installation quick and easy

- Digital push-button zero and span simplify calibration over typical turn-potentiometers

- An optional 3.5 digit LCD shows process and engineering units

- A single bush button allows field selection of 4 to 6 engineering units depending on range on LCD models

Specifications

- Service: Air and non-combustible, compatible gases.

- Wetted Materials: Consult Factory.

- Accuracy: ±1% F.S. at 70°F.

- Stability: +1% F.S./yr.

- Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

- Pressure Limits: 10 psig (0.69 bar).

- Thermal Effect: ±0.055% F.S./°F (0.099% F.S./°C).

- Power Requirements: 10-35 VDC (2 wire).

- Output Signal: 4 to 20 mA.

- Zero and Span Adjustments: Digital push-button zero and span.

- Loop Resistance: DC: 0-1250 ohms maximum.

- Current Consumption: DC: 38 mA maximum.

- Electrical Connections: Screw-type terminal block.

- Display: 3.5 digit LCD, 0.7" height.

- Process Connections: 1/8" I.D. tubing.

- Mounting Orientation: Vertical.

- Weight: 4.8 oz (136 g).

Model

DM-2006-LCD

Description

Differential pressure transmitter, range 3.00" w.c., 746 Pa, 76.2 mm w.c., 7.46 mbar, .746 kPa, .108 psi.

Reliable Pressure Measurement

Engineered for precision, the DM-2006-LCD delivers 1% full-scale accuracy over a scale range of 0 to 250 Pa. This enables consistent monitoring in environments requiring sensitive detection of pressure fluctuations, supporting process reliability in HVAC and cleanroom applications.

User-Friendly Operation and Adjustments

Front-panel accessible zero and span controls simplify calibration and adjustment, allowing operators to achieve optimal performance with minimal effort. The clear LCD digital display ensures immediate access to real-time measurements, streamlining facility management tasks.

Flexible and Durable Design

Housed in an ABS plastic enclosure with IP54 protection, the DM-2006-LCD withstands challenging industrial environments. Panel mounting and a screw terminal connection ensure swift, secure installation. The transmitter comes supplied with a mounting bracket for added convenience.

FAQs of Dwyer DM-2006-LCD PRESSURE TRANSMITTER:

Q: How do I install the Dwyer DM-2006-LCD pressure transmitter?

A: The DM-2006-LCD is designed for panel mounting and comes with a mounting bracket. Ensure an appropriate panel cutout to fit its 96 x 96 mm outer size, secure the unit using the bracket, and connect the electrical wires to the screw terminals as per the wiring diagram provided in the manual.Q: What type of media can be measured with this transmitter?

A: This transmitter is calibrated to measure the pressure of air and non-corrosive gases only. It should not be used for corrosive substances or liquids, as this may damage the sensor and compromise its accuracy.Q: Where can the zero and span of the transmitter be adjusted?

A: The zero and span adjustment controls are accessible directly through the front panel of the device, allowing straightforward calibration and fine-tuning without having to disassemble or remove the unit from the panel.Q: What are the main benefits of its LCD digital display?

A: The LCD digital display provides highly visible, real-time pressure readings, improving readability and enabling users to monitor system status at a glance. This helps technicians quickly identify abnormal conditions and respond promptly.Q: When should I use the Dwyer DM-2006-LCDs span and zero adjustments?

A: Adjust the span and zero settings during initial setup, periodic calibration, or after any maintenance procedure that might affect the measurement accuracy. This ensures the transmitter maintains consistent and dependable performance.Q: What kind of environments is this transmitter suitable for?

A: Thanks to its IP54 enclosure rating and ABS housing, the DM-2006-LCD is suitable for indoor industrial settings such as HVAC systems, laboratories, cleanrooms, and process plants where dust and occasional splashes may occur.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer Differential Pressure Transmitter Wholesale Category

Dwyer DM-2012-LCD PRESSURE TRANSMITTER

Scale Range : 1000 to +1000 Pa (Pascal)

Seal Material : BunaN

Display : LCD Digital Display

Finishing : Other, Powder Coated / Matt Finish

Accuracy : 1% of Full Scale

Measure Pressure Of : Other, Air and Noncorrosive Gases

DWYER Differential Pressure Transmitter Series DM-2000

Scale Range : 0100 Pa to 05000 Pa (various models)

Seal Material : EPDM or Equivalent

Display : Digital LCD

Finishing : Other, Matte/Standard industrial

Accuracy : 1% of FS

Measure Pressure Of : Other, Air and Noncombustible Gases

Dwyer DM-2013-LCD PRESSURE TRANSMITTER

Scale Range : 0 to 1000 Pa, 0 to 2000 Pa, 0 to 3000 Pa, 0 to 5000 Pa (selectable)

Seal Material : Synthetic Rubber

Display : LCD Digital Display

Finishing : Other, Powder Coated

Accuracy : 1% of Full Scale

Measure Pressure Of : Other, Air and noncorrosive gases

Dwyer DM-2002-LCD Differential Pressure Transmitter

Scale Range : 02000 Pa

Seal Material : Silicone

Display : LCD Digital Display

Finishing : Other, Powder Coated

Accuracy : 1% of Full Scale

Measure Pressure Of : Other, Air and Noncorrosive Gases

Send Inquiry

Send Inquiry