Dwyer DM-2002-LCD Differential Pressure Transmitter

Dwyer DM-2002-LCD Differential Pressure Transmitter Specification

- Display

- LCD Digital Display

- Grade

- Industrial

- Outer Size

- 112 mm x 82 mm x 53 mm

- Sensor Type

- Differential Pressure Sensor

- Thread

- 1/8 Female NPT

- Seal Material

- Silicone

- Material

- Polycarbonate Housing

- Processing Type

- Electronic

- Mount Type

- Wall Mount

- Scale Range

- 0-2000 Pa

- Accuracy

- 1% of Full Scale

- Finishing

- Powder Coated

- Measure Pressure Of

- Air and Non-corrosive Gases

- Accessories

- Mounting hardware included

Dwyer DM-2002-LCD Differential Pressure Transmitter Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Africa, Central America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Dwyer DM-2002-LCD Differential Pressure Transmitter

Dwyer DM-2002-LCD Differential Pressure Transmitter- A wide range of models are available factory calibrated to specific ranges

- Pressure connections are inherent to the glass filled plastic molded housing making installation quick and easy

- Digital push-button zero and span simplify calibration over typical turn-potentiometers

- An optional 3.5 digit LCD shows process and engineering units

- A single bush button allows field selection of 4 to 6 engineering units depending on range on LCD models

- Service: Air and non-combustible, compatible gases.

- Wetted Materials: Consult Factory.

- Accuracy: ±1% F.S. at 70°F.

- Stability: +1% F.S./yr.

- Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

- Pressure Limits: 10 psig (0.69 bar).

- Thermal Effect: ±0.055% F.S./°F (0.099% F.S./°C).

- Power Requirements: 10-35 VDC (2 wire).

- Output Signal: 4 to 20 mA.

- Zero and Span Adjustments: Digital push-button zero and span.

- Loop Resistance: DC: 0-1250 ohms maximum.

- Current Consumption: DC: 38 mA maximum.

- Electrical Connections: Screw-type terminal block.

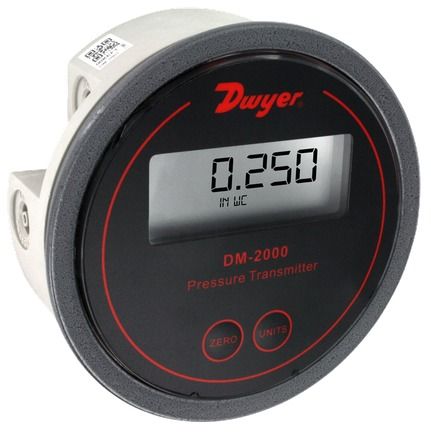

- Display: 3.5 digit LCD, 0.7" height.

- Process Connections: 1/8" I.D. tubing.

- Mounting Orientation: Vertical.

- Weight: 4.8 oz (136 g).

- DM-2002-LCD

Description

- Differential pressure transmitter, range .250" w.c., 62.2 Pa, 6.35 mm w.c., .622 mbar.

Reliable Industrial Performance

Engineered for demanding environments, the DM-2002-LCD transmitter boasts high accuracy and a fast response time of less than 1 second. Powder-coated and housed in polycarbonate, it meets IP54 standards for protection while handling pressures up to 2000 Pa.

Simple Installation and Operation

Installation is streamlined with wall mounting and a screw terminal block for electrical connections. The clear LCD display makes real-time readings accessible, while the 4-20 mA output supports seamless integration with standard industrial systems.

Versatile and Safe Application

Suitable for air and non-corrosive gases, the device is ideal for HVAC, cleanrooms, and process monitoring. Its CE certification and robust construction ensure safe operation and long-term durability in varied industrial settings.

FAQs of Dwyer DM-2002-LCD Differential Pressure Transmitter:

Q: How is the Dwyer DM-2002-LCD Differential Pressure Transmitter installed?

A: The DM-2002-LCD comes with mounting hardware and is designed for convenient wall mounting. Electrical connections are made via a user-friendly screw terminal block, simplifying setup in industrial or commercial environments.Q: What gases can be measured with this differential pressure transmitter?

A: This device measures the differential pressure of air and non-corrosive gases only, ensuring accurate results and long-term reliability when used within its specified pressure range.Q: When is the best time to calibrate or maintain the DM-2002-LCD?

A: For optimal accuracy, calibration should be performed according to your facilitys standard maintenance schedule or as recommended by local regulations for pressure instrumentation.Q: Where can the DM-2002-LCD be effectively used?

A: This transmitter is suitable for use in cleanrooms, HVAC systems, industrial processes, or any application requiring precise monitoring of low-pressure or differential pressure in non-corrosive gas environments.Q: What are the main benefits of using an LCD digital display on this transmitter?

A: The integrated LCD display provides instant, clear readings, enabling quick status checks and adjustments without the need for external measuring devices.Q: How does the device ensure safety and durability for industrial applications?

A: With an IP54 protection class, polycarbonate housing, silicone seals, and CE marking, the transmitter is built to withstand challenging industrial environments, ensuring long-lasting and safe operation.Q: What output signal does the DM-2002-LCD provide and why is it beneficial?

A: It provides a 4-20 mA output signal, widely recognized for its reliability and compatibility with industrial control and monitoring systems, supporting efficient data transfer and process integration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer Differential Pressure Transmitter Wholesale Category

Dwyer DM-2006-LCD PRESSURE TRANSMITTER

Accuracy : 1% full scale

Accessories : Mounting bracket included

Mount Type : Other, Panel Mount

Scale Range : 0 to 250 Pa

Material : Other, ABS Plastic Housing

Seal Material : Nitrile Rubber

Dwyer DM-2012-LCD PRESSURE TRANSMITTER

Accuracy : 1% of Full Scale

Accessories : Mounting Screws, User Manual

Mount Type : Other, Panel Mount or Surface Mount

Scale Range : 1000 to +1000 Pa (Pascal)

Material : Other, ABS Plastic Housing

Seal Material : BunaN

Dwyer DM-2004-LCD PRESSURE TRANSMITTER

Accuracy : 1% of Full Scale

Accessories : Mounting Hardware, User Manual

Mount Type : Other, Wall Mount or Surface Mount

Scale Range : 0250 Pa (other ranges available)

Material : Other, ABS Plastic Housing

Seal Material : Silicone

Dwyer DM-2003-LCD Differential Pressure Transmitter

Accuracy : 1% F.S.

Accessories : Mounting Kit Included

Mount Type : Other, Panel/Wall Mount

Scale Range : 0500 Pa

Material : Other, ABS Plastic Housing

Seal Material : Nitrile

Send Inquiry

Send Inquiry