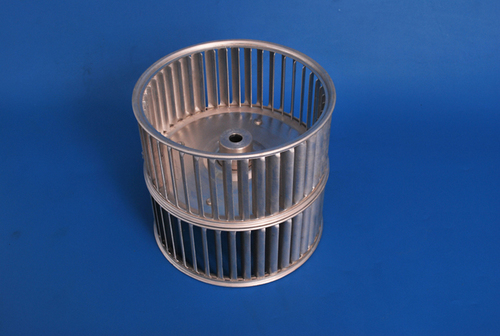

DIDW Centrifugal Fan 250 MM X 178 MM

DIDW Centrifugal Fan 250 MM X 178 MM Specification

- Efficiency

- Up to 80%

- Temperature

- Ambient to 60C

- Automation Grade

- Manual

- Orientation

- Double Inlet Double Width

- Usage & Applications

- HVAC Systems, Air Handling Units, Industrial Ventilation

- Power Source

- Electric

- Air Flow

- 3500 CFM

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- <82 dB(A)

- Capacity

- 3500 CFM

- Voltage

- 415 V

- Weight

- Approx. 32 kg

- Dimension (L*W*H)

- 250 mm x 178 mm

- Surface

- Powder Coated

DIDW Centrifugal Fan 250 MM X 178 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Africa, Central America, Middle East, South America, Asia

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 250 MM X 178 MM

DIDW Centrifugal Fan 250 MM X 178 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 37 | ETIP 10 70 | 250 X 178X 210 | 10 X 7 | 12.70 (1/2) & 15 MM | AL. / GI. |

Superior Air Flow Technology

This centrifugal fan employs a double inlet, double width (DIDW) design with backward-curved impeller blades, optimizing airflow at a high capacity of 3500 CFM. Its direct drive mechanism ensures efficient power transmission, minimal maintenance, and consistent operation. The robust construction and epoxy paint finish offer durability and resistance to harsh industrial environments.

Versatile Applications in Ventilation

Engineered for deployment in HVAC systems, air handling units, and industrial ventilation setups, this fan adapts seamlessly to diverse air movement requirements. The base mounting and flanged connections promote straightforward installation, making it suitable for both new and retrofit projects across commercial and industrial sectors in India.

Reliability and Performance

Operating at up to 80% efficiency and designed with sealed ball bearings and air-cooled technology, the fan maintains longevity even under heavy use. It is built for ambient to 60C environments and high relative humidity (up to 95%), ensuring safe performance at altitudes up to 2000 meters. Noise emissions remain below 82 dB(A), supporting quieter workspaces.

FAQs of DIDW Centrifugal Fan 250 MM X 178 MM:

Q: How is the DIDW Centrifugal Fan installed in an industrial or HVAC setup?

A: This fan is base-mounted with flanged connections for secure installation, enabling easy integration into air handling units or ductwork in HVAC and industrial ventilation systems. Professional installation is recommended to ensure optimal alignment and safety.Q: What are the main benefits of the backward curved impeller design for this model?

A: The backward curved impeller enhances static pressure capability, provides high efficiency (up to 80%), and reduces the risk of dust accumulation, allowing for quieter and more reliable operation in demanding applications.Q: Where can the DIDW Centrifugal Fan be effectively used?

A: This fan is ideal for environments requiring robust air movement, such as HVAC systems, air handling units, and industrial ventilation, particularly in commercial buildings, factories, and process industries.Q: What process does the fan use to control noise levels?

A: The fans design, including backward curved blades and sealed ball bearings, mitigates vibration and airflow turbulence, maintaining noise emissions below 82 dB(A) for quieter operation in occupied spaces.Q: When should routine maintenance be performed for this fan?

A: Routine maintenance, including checking bearings, motor health, and cleaning the impeller, should be performed every 612 months depending on operational intensity, in accordance with manufacturer guidelines to ensure optimal performance and longevity.Q: What is the operating temperature range and humidity tolerance for this centrifugal fan?

A: The unit functions efficiently in ambient temperatures up to 60C and can operate reliably in areas with relative humidity up to 95%, making it suitable for a variety of climates and industrial conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 300 MM X 203 MM

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Product Type : Double Inlet Double Width (DIDW) Centrifugal Fan

Material : Mild Steel (MS)

Voltage : 415 V AC

Efficiency : Up to 80%

DIDW Centrifugal Fan 610 MM X 455 MM

Price 21000 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW Centrifugal Fan

Material : Mild Steel

Voltage : 415 V

Efficiency : High Efficiency

DIDW Centrifugal Fan 115 MM X 127 MM

Price 600 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW (Double Inlet Double Width) Centrifugal Fan

Material : Mild Steel (MS) / Galvanized Iron (GI)

Voltage : 230V / 415V AC

Efficiency : High efficiency up to 78%

DIDW Centrifugal Fan 200 MM X 279 MM

Price 1500 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW Centrifugal Fan

Material : Mild Steel

Voltage : 415 V

Efficiency : Up to 75%

Send Inquiry

Send Inquiry