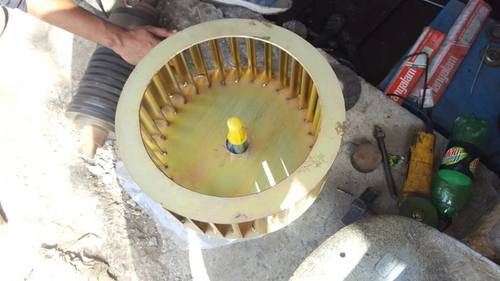

DIDW Centrifugal Fan 200 MM X 279 MM

DIDW Centrifugal Fan 200 MM X 279 MM Specification

- Air Flow

- 800 to 1250 CFM

- Orientation

- Double Inlet Double Width

- Temperature

- Maximum up to 60C

- Automation Grade

- Manual

- Power Source

- Electric

- Efficiency

- Up to 75%

- Usage & Applications

- HVAC, Industrial Ventilation, Air Handling Units, Dust Collection

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Cooling System

- Air Cooling

- Noise Level

- Less than 80 dB

- Processing Time

- Continuous Duty

- Capacity

- Customizable as per requirement

- Voltage

- 415 V

- Weight

- Approx. 32 kg

- Dimension (L*W*H)

- 200 mm x 279 mm

- Surface

- Powder Coated

DIDW Centrifugal Fan 200 MM X 279 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 200 MM X 279 MM

DIDW Centrifugal Fan 200 MM X 279 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 29 | ETIP 8 11 | 200 X 279 X 158 | 8 X 11 | 12.70 (1/2) & 15 MM | AL. / GI. |

Versatile Performance and Customizable Design

Engineered for dependable operation, this DIDW centrifugal fan allows you to select from multiple drive and mounting configurations for seamless integration into various air-moving applications. The aerodynamic backward curved impeller maximizes energy efficiency while minimizing noise, making it suitable for both industrial and commercial environments. With customizable capacity, operating speeds, and powder-coated, heavy-duty steel construction, this fan is built to meet specific site requirements and deliver lasting performance.

Robust Construction and Reliable Operation

Manufactured with heavy gauge mild steel and finished in blue or customized colors, this centrifugal fan withstands harsh industrial conditions. Double inlet, double width orientation ensures higher air flow rates, while efficient air cooling supports continuous 24/7 operations. The fan impeller is designed for smooth, vibration-free operation, with a static pressure range of 25 to 75 mm WG, catering to diverse applications including HVAC and dust collection.

FAQs of DIDW Centrifugal Fan 200 MM X 279 MM:

Q: How do I select the appropriate configuration for my DIDW Centrifugal Fan application?

A: Consider your facilitys air flow requirements, preferred drive type (belt or direct drive), and mounting constraints. The DIDW Centrifugal Fan supports capacities from 800 to 1250 CFM, with static pressure options, speed ranges (9602800 RPM), and customizable voltage (415 V). Consult with the manufacturer to determine the optimal configuration for your HVAC or industrial ventilation system.Q: What are the benefits of an aerodynamic backward curved impeller in this fan?

A: The aerodynamic backward curved design increases efficiency by reducing energy losses and provides stable airflow while minimizing noise. This impeller type also offers enhanced durability in dust-laden environments and requires less maintenance compared to forward-curved designs.Q: When should I use a belt drive versus a direct drive on this centrifugal fan?

A: A belt drive is advantageous when variable speed or flexibility in motor placement is required, while direct drive offers a compact setup with fewer moving parts and reduced maintenance. Your choice depends on spatial constraints, desired control over fan speed, and application-specific requirements.Q: Where can this centrifugal fan be installed?

A: Its base-mounted, double inlet, double width design allows for versatile installation in commercial and industrial settings, including air handling units, HVAC systems, dust collection units, and general ventilation applications. Ensure there is adequate space for installation and servicing as per manufacturer guidelines.Q: What is the process for ordering and customizing the fan to my requirements?

A: Contact the manufacturer, supplier, or authorized dealer in India with your specifications, including required capacity, color preference, number of blades, drive type, and application standards. They will guide you through customization options and provide support throughout the ordering and installation process.Q: How is after-sales support provided for this product?

A: After-sales support includes technical assistance for installation, operation, and maintenance queries, as well as spare parts availability. This ensures long-term satisfaction and consistent performance of your DIDW Centrifugal Fan.Q: What is the maximum operating temperature and how does it impact usage?

A: The fan is designed for continuous duty at temperatures up to 60C, making it suitable for most HVAC and industrial ventilation applications. Exceeding this temperature could affect performance and lifespan, so ensure operating conditions comply with specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 180 MM X 228 MM

Price 1250 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Power Source : Electric

Usage & Applications : Industrial ventilation, air handling units, HVAC & Exhaust applications

Dimension (L*W*H) : 180 mm x 228 mm (Impeller Size)

DIDW Centrifugal Fan 160 MM X 152 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Material : Galvanized Steel

Power Source : Electric

Usage & Applications : HVAC, Ventilation, Air Handling Units, Clean Rooms

Dimension (L*W*H) : 160 mm x 152 mm

DIDW Centrifugal Fan 250 MM X 254 MM

Price 2500 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Power Source : Electric

Usage & Applications : Ventilation, HVAC, Industrial Air Handling

Dimension (L*W*H) : 250 mm x 254 mm

DIDW Centrifugal Fan 330 MM X 330 MM

Price 7500 INR

Minimum Order Quantity : 12 Pieces

Material : Galvanized Iron (GI) / Mild Steel (MS)

Power Source : Electric

Usage & Applications : Industrial ventilation, HVAC, air handling units, exhaust and supply systems

Dimension (L*W*H) : 330 mm x 330 mm

Send Inquiry

Send Inquiry