DIDW Centrifugal Fan 250 MM X 254 MM

DIDW Centrifugal Fan 250 MM X 254 MM Specification

- Power Source

- Electric

- Usage & Applications

- Ventilation, HVAC, Industrial Air Handling

- Air Flow

- 1100-1700 m/hr

- Orientation

- Double Inlet, Double Width

- Temperature

- -10 to 55C

- Efficiency

- High efficiency

- Automation Grade

- Manual

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Less than 85 dB

- Processing Time

- Continuous

- Capacity

- Depends on application

- Voltage

- 220-240 V AC

- Weight

- Approx. 18-22 kg

- Dimension (L*W*H)

- 250 mm x 254 mm

- Surface

- Powder Coated

DIDW Centrifugal Fan 250 MM X 254 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 250 MM X 254 MM

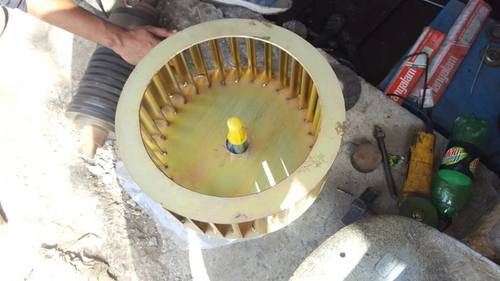

DIDW Centrifugal Fan 250 MM X 254 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 40 | ETIP 10 10 | 250 X 254X 210 | 10 X 10 | 12.70 (1/2) & 15 MM & 20 MM | AL. / GI. |

Durability Meets Versatility

Constructed from high-grade mild steel and finished with epoxy & powder coating, this centrifugal fan excels in durability. Designed for over five years of service, it delivers consistent performance in environments ranging from -10C to 55C. Choose floor or base mounting for seamless installation across various settings.

Optimal Performance and Power

Equipped with a dynamically balanced impeller and supported by a heavy-duty ball bearing system, the fan ensures smooth air delivery with minimal vibration. Motor power options from 0.75 kW to 3 kW, along with adjustable speeds, offer flexibility to address diverse airflow requirementsperfect for both industrial and commercial HVAC applications.

FAQs of DIDW Centrifugal Fan 250 MM X 254 MM:

Q: How do I install the DIDW Centrifugal Fan 250 MM X 254 MM?

A: Installation is straightforward, thanks to its floor or base mounting design. Ensure the frame is securely mounted and aligned. The fan supports both rectangular and square duct connections, and can be paired with either a direct or belt drive as per your requirement.Q: What are the key benefits of using a DIDW (Double Inlet Double Width) centrifugal fan in ventilation systems?

A: The double inlet, double width configuration maximizes airflow while maintaining compact dimensions. This design enhances efficiency, reduces noise (below 85 dB), and supports higher capacitiesmaking it ideal for industrial air handling and HVAC applications.Q: When should maintenance be performed on this centrifugal fan?

A: Thanks to its robust construction and high-quality bearings, maintenance is minimal. Routine inspections and cleaning are typically all thats required. Easy access design allows for quick servicing, prolonging the fans operational lifespan.Q: Where can this fan be effectively used?

A: Common usage scenarios include ventilation systems, commercial and industrial HVAC, workshops, and various facilities needing reliable air movement. Its durability and flexibility make it suitable for both new installations and retrofit projects across India.Q: What is the process for selecting the appropriate motor power and speed for my application?

A: Motor selection depends on your air volume and static pressure requirements. Available options range from 0.75 kW to 3 kW, with operational speeds between 1450 and 2850 RPM. Its recommended to evaluate your ducting and airflow needs, then consult with the supplier or manufacturer for optimal matching.Q: How does the fan contribute to improved energy efficiency?

A: The fan boasts a high-efficiency mild steel impeller and is designed for minimal energy loss. Its dynamically balanced construction ensures smooth operation, reducing power consumption while delivering the required air flowresulting in lower electricity costs for continuous use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 280 MM X 150 MM

Price 2500 INR

Minimum Order Quantity : 12 Pieces

Capacity : 2500 CFM

Material : Mild Steel

Power Source : Electric

Usage & Applications : Ventilation, HVAC, Industrial Air Handling

DIDW Centrifugal Fan 200 MM X 152 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Capacity : 400 600 CFM

Material : Mild Steel / Galvanized Iron / Stainless Steel

Power Source : Electric

Usage & Applications : HVAC, Ventilation, Air Handling Units, Exhaust & Supply Systems

DIDW Centrifugal Fan 160 MM X 228 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Capacity : Custom as per requirement

Material : Mild Steel

Power Source : Electric

Usage & Applications : Ventilation, HVAC, Industrial Process

DIDW Centrifugal Fan 455 MM X 455 MM

Price 18000 INR

Minimum Order Quantity : 12 Pieces

Capacity : Customizable

Material : Mild Steel

Power Source : Electric

Usage & Applications : Ventilation, Exhaust, HVAC, Industrial Process

Send Inquiry

Send Inquiry