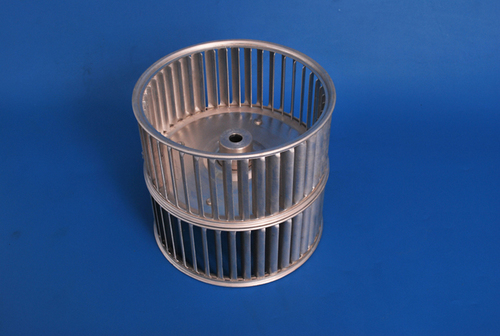

DIDW Centrifugal Fan 280 MM X 150 MM

DIDW Centrifugal Fan 280 MM X 150 MM Specification

- Power Source

- Electric

- Air Flow

- 2500 CFM (Max)

- Orientation

- Double Inlet, Double Width

- Temperature

- Max. 80C

- Usage & Applications

- Ventilation, HVAC, Industrial Air Handling

- Efficiency

- Up to 75%

- Automation Grade

- Manual

- Product Type

- DIDW Centrifugal Fan

- Material

- Mild Steel

- Cooling System

- Air Cooling

- Noise Level

- Less than 80 dB

- Processing Time

- Continuous

- Capacity

- 2500 CFM

- Voltage

- 415 V

- Weight

- Approx. 45 kg

- Dimension (L*W*H)

- 280 mm x 150 mm

- Surface

- Powder Coated

DIDW Centrifugal Fan 280 MM X 150 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, South America, Asia, Central America, North America

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 280 MM X 150 MM

DIDW Centrifugal Fan 280 MM X 150 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 43 | ETIP 11 60 | 280 X 150X 229 | 11 X 6 | 12.70 (1/2) & 15 MM & 20 MM | AL. / GI. |

Superior Industrial Air Flow

Designed for maximum performance, this centrifugal fan achieves up to 2500 CFM airflow due to its optimized double inlet, double width configuration. With 12-16 blades and an impeller available in forward or backward curve, the system delivers powerful, efficient air movement for HVAC systems, industrial ventilation, and ambient cooling applications.

Rugged and Reliable Construction

Built from powder-coated mild steel and a welded steel sheet housing, the DIDW Centrifugal Fan ensures durability and resistance to industrial wear. Its IP54 protection grade shields internal components from dust and moisture, making it reliable for continuous operation in challenging environments up to 80C.

Versatile Installation and Operation

Floor or base mounted with flexible connection options (flange or duct), this fan integrates seamlessly into various industrial setups. The belt-driven system, paired with air cooling, ball bearings, and manual automation, guarantees smooth running and easy maintenance, while its compact design suits confined spaces.

FAQs of DIDW Centrifugal Fan 280 MM X 150 MM:

Q: How do I select between forward curved and backward curved impeller types for this centrifugal fan?

A: The choice between forward and backward curved impeller depends on your applications pressure and airflow requirements. Forward curved impellers are ideal for low-pressure, high-volume scenarios like general ventilation, while backward curved impellers excel in higher pressure applications such as HVAC and industrial air handling. Consider your required static pressure and flow when deciding.Q: What is the recommended process for installing the DIDW Centrifugal Fan?

A: Install the fan on a stable floor or base, using the mounting provisions provided. Ensure there is proper alignment of the drive belt and secure flange or duct connections as required. Make electrical connections (415 V) in accordance with local wiring codes, and confirm the power source is capable of supporting continuous operation.Q: When should the centrifugal fan be maintained or serviced?

A: Routine maintenancesuch as checking the belt tension, cleaning the air inlets, and ensuring the bearings are lubricatedshould be conducted periodically according to your operations usage intensity. Scheduled checks every three to six months help keep the fan running efficiently and extend its lifespan.Q: Where can this centrifugal fan be effectively utilized?

A: This fan is highly effective in ventilation systems, HVAC applications, industrial air handling, and spaces requiring steady, controlled airflow. Its designed for environments that demand high reliability and robust performance, such as manufacturing facilities, warehouses, and commercial buildings across India.Q: What are the primary benefits of using this double inlet, double width centrifugal fan?

A: The main advantages include high efficiency (up to 75%), the ability for continuous operation, low maintenance needs, and quiet performance. Its durable build and flexibility in mounting and connection make it suitable for a wide range of demanding industrial and commercial applications.Q: How does the air cooling system contribute to the fans performance?

A: The integrated air cooling system helps maintain optimal operating temperatures for the motor and internal components, preventing overheating during continuous use, thereby enhancing the fans reliability and operational life.Q: What usage limits does this fan have for temperature and noise?

A: The DIDW Centrifugal Fan is capable of operating in environments with temperatures up to 80C and maintains a noise output below 80 dB, making it suitable for most industrial and commercial settings where noise control is a concern.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 530 MM X 380 MM

Price 17000 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Power Source : Electric

Dimension (L*W*H) : 530 mm x 380 mm

Surface : Powder Coated

DIDW Centrifugal Fan 280 MM X 200 MM

Price 3000 INR

Minimum Order Quantity : 12 Pieces

Material : Galvanized Steel / Mild Steel

Power Source : Three Phase Electric

Dimension (L*W*H) : 280 mm x 200 mm x 350 mm

Surface : Powder coated

DIDW Centrifugal Fan 250 MM X 228 MM

Price 2000 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Power Source : Electric

Dimension (L*W*H) : 250 mm x 228 mm (Impeller Size)

Surface : Powder coated

DIDW Centrifugal Fan 115 MM X 127 MM

Price 600 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel (MS) / Galvanized Iron (GI)

Power Source : Electric

Dimension (L*W*H) : 115 mm x 127 mm (Impeller Size)

Surface : Powder Coated / Galvanized

Send Inquiry

Send Inquiry