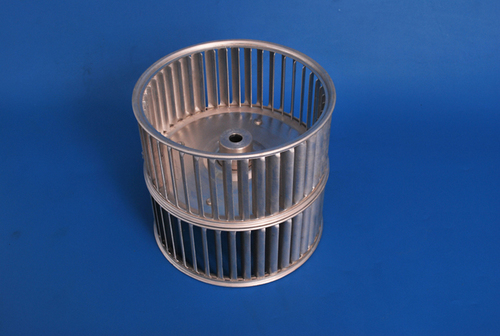

DIDW Centrifugal Fan 115 MM X 127 MM

DIDW Centrifugal Fan 115 MM X 127 MM Specification

- Power Source

- Electric

- Efficiency

- High efficiency up to 78%

- Automation Grade

- Manual

- Measurement

- Impeller Diameter and Width

- Temperature

- Up to 60C

- Instruments Type

- Fan/Blower

- Orientation

- Horizontal

- Air Flow

- 100 - 1800 m/hr

- Usage & Applications

- HVAC systems, Exhaust, Ventilation, Air Handling Units

- Product Type

- DIDW (Double Inlet Double Width) Centrifugal Fan

- Material

- Mild Steel (MS) / Galvanized Iron (GI)

- Cooling System

- Air Cooled

- Noise Level

- Below 75 dB

- Processing Time

- Continuous

- Capacity

- Up to 1800 m/hr

- Voltage

- 230V / 415V AC

- Weight

- Approx. 5-7 kg

- Dimension (L*W*H)

- 115 mm x 127 mm (Impeller Size)

- Surface

- Powder Coated / Galvanized

DIDW Centrifugal Fan 115 MM X 127 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Days after Acceptance (DA), Delivery Point (DP), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Central America, Africa, South America, Asia, North America

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 115 MM X 127 MM

DIDW Centrifugal Fan 115 MM X 127 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH | | ||

| 1 | ETIP 45 50 | 115 X 127 X 75 | 4.5 X 5 | 6 & 8 MM | AL. / GI. |

Reliable and Versatile Ventilation Solution

DIDW Centrifugal Fans are designed to deliver optimal airflow for HVAC systems, exhaust, and ventilation across commercial and industrial settings. With impeller sizes of 115 mm x 127 mm and flexible mounting and connection options, this fan ensures seamless integration into various infrastructures. Its high-efficiency and anti-corrosive finish make it a long-lasting solution, while sealed bearings and air-cooled engine contribute to nearly maintenance-free and continuous operation.

Engineered for Safety and Durability

The fans IP55 motor protection and sealed ball bearings extend operational safety and service life, minimizing downtime and repairs. Manufactured using mild steel or galvanized iron and finished with powder coating or galvanizing, it withstands environmental challenges and resists corrosion efficiently. Accessories like mounting frames and flexible connectors further enhance installation and compatibility, catering to both rapid and long-term demands.

FAQs of DIDW Centrifugal Fan 115 MM X 127 MM:

Q: How should I install the DIDW Centrifugal Fan for optimal performance?

A: The DIDW Centrifugal Fan is base-mounted for stability and can be connected using either flanged or slip-on fittings. Ensure you follow manufacturer guidelines for mounting orientation (horizontal) and allow for proper air clearance around the fan. It is suitable for integration into HVAC, exhaust, or air handling units.Q: What maintenance is required for this centrifugal fan?

A: Thanks to sealed ball bearings and an air-cooled system, the fan is virtually maintenance free. However, periodic checks of electrical connections and cleaning of the impeller and housing are recommended to maintain peak efficiency and extend the service life, which can be up to 8 years with proper care.Q: When is it recommended to use the backward or forward curved impeller?

A: Backward curved impellers are ideal for higher static pressure and energy efficiency, making them suitable for filters or ducts with resistance. Forward curved impellers provide higher airflow at lower pressures, appropriate for general ventilation where moving large volumes of air is the priority.Q: Where can this centrifugal fan be effectively utilized?

A: This fan is designed for commercial and industrial environments, including HVAC systems, exhaust applications, ventilation for factories, warehouses, kitchens, and air handling units in office or production facilities. Its robust construction and anti-corrosive finish make it suitable for demanding conditions.Q: What process ensures its anti-corrosive properties?

A: The fans components are made from mild steel or galvanized iron and finished with powder coating or galvanizing. These processes create a protective barrier resisting rust and environmental wear, ensuring longevity even in humid or corrosive atmospheres.Q: What are the key benefits of choosing this fan for ventilation needs?

A: Key advantages include high efficiency (up to 78%), quiet operation (below 75 dB), low maintenance, robust anti-corrosive construction, and versatile installation options. It also offers reliable motor protection (IP55) and is suitable for continuous duty in demanding settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 380 MM X 380 MM

Price 9000 INR

Minimum Order Quantity : 12 Pieces

Voltage : 220380 V

Automation Grade : Semi Automatic

Capacity : Variable, up to 4200 CMH

Efficiency : Up to 75%

DIDW Centrifugal Fan 530 MM X 380 MM

Price 17000 INR

Minimum Order Quantity : 12 Pieces

Voltage : 415 V

Automation Grade : Manual

Capacity : 500012000 m3/h

Efficiency : Up to 80%

DIDW Centrifugal Fan 610 MM X 530 MM

Price 20000 INR

Minimum Order Quantity : 12 Pieces

Voltage : 415 V

Automation Grade : SemiAutomatic

Capacity : Custom as per requirement

Efficiency : High Efficiency

DIDW Centrifugal Fan 610 MM X 455 MM

Price 21000 INR

Minimum Order Quantity : 12 Pieces

Voltage : 415 V

Automation Grade : SemiAutomatic

Capacity : Depends on Air Flow Rate

Efficiency : High Efficiency

Send Inquiry

Send Inquiry