DIDW Centrifugal Fan 160 MM X 152 MM

DIDW Centrifugal Fan 160 MM X 152 MM Specification

- Measurement

- Static Pressure/Flow

- Instruments Type

- Fan/Blower

- Power Source

- Electric

- Air Flow

- 400 m/h

- Orientation

- Double Inlet Double Width

- Temperature

- Up to 60C

- Usage & Applications

- HVAC, Ventilation, Air Handling Units, Clean Rooms

- Efficiency

- High Efficiency

- Automation Grade

- Manual

- Product Type

- DIDW Centrifugal Fan

- Material

- Galvanized Steel

- Cooling System

- Air Cooled

- Noise Level

- < 80 dB

- Processing Time

- Continuous

- Capacity

- 400 m/h

- Voltage

- 230 V

- Weight

- 7 kg

- Dimension (L*W*H)

- 160 mm x 152 mm

- Surface

- Powder Coated

DIDW Centrifugal Fan 160 MM X 152 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America, North America

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 160 MM X 152 MM

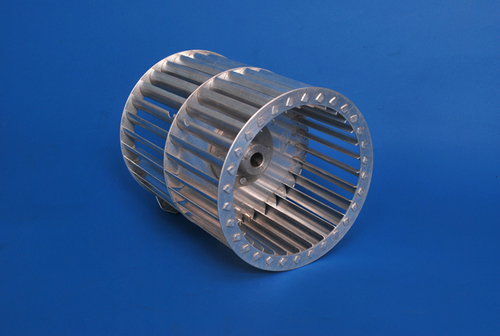

DIDW Centrifugal Fan 160 MM X 152 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 12 | ETIP 65 60 | 160 X 152 X 135 | 6.5 X 6 | 12.70 (1/2) & 15 MM | AL. / GI. |

Robust Double Inlet, Double Width Design

This centrifugal fan features a double inlet, double width configuration, maximizing air flow and efficiency for demanding industrial and commercial spaces. The galvanized steel construction provides excellent corrosion resistance and durability, suiting environments where reliability and long operational life are essential.

Engineered for High Performance

With a precision-balanced 12-blade impeller and 1450 RPM speed, the fan achieves a steady airflow of 400 m/h while maintaining static pressures up to 50 mmWC. Low noise operation ensures comfort and compliance in enclosed spaces, making it perfect for modern HVAC, clean rooms, and air handling units.

Simple Installation & Reliable Operation

The flange-mount design simplifies installation in diverse ventilation systems. The single-phase, asynchronous motor ensures energy-efficient, continuous operation, while the air-cooled mechanism protects the system even during extended service. Maintenance is straightforward, promoting fuss-free, long-term use.

FAQs of DIDW Centrifugal Fan 160 MM X 152 MM:

Q: How do I install the DIDW Centrifugal Fan in my HVAC or ventilation system?

A: This fan is designed for flange mounting, allowing straightforward integration into HVAC ducts, air handling units, or ventilation shafts. Ensure it is securely fixed using standard flange bolts and connect the wiring to a 230V power source, following local electrical codes.Q: What types of environments or applications is this centrifugal fan suitable for?

A: The fan is ideal for industrial and commercial ventilation, HVAC, clean rooms, and air handling units. It is suitable where high airflow (400 m/h), controlled static pressure, and corrosion resistance are required, such as factories, laboratories, workshops, and offices.Q: What benefits does the double inlet, double width design provide?

A: The double inlet, double width structure enhances the airflow capacity and enables more efficient, balanced distribution. This results in higher ventilation rates, improved air quality, and greater energy savings compared to single inlet designs.Q: How durable and corrosion-resistant is the fan construction?

A: Constructed from galvanized steel with a powder-coated matte finish, the fan provides excellent resistance against rust and corrosion. This ensures long service life and dependable performance in humid or harsh industrial environments.Q: When should I choose this model over other fan types?

A: Choose this model when you require consistent, high-efficiency performance at moderate static pressures, combined with quiet operation and compact dimensions. Its robust construction and ease of maintenance make it preferable for continuous use in demanding settings.Q: What is the process for maintaining or cleaning the fan?

A: Periodically inspect for dust or debris accumulation on the blades or housing. Disconnect power before cleaning, and use a soft brush or compressed air to remove buildup. Lubrication of motor bearings is generally not required for air-cooled, sealed models, but follow the manufacturers maintenance guidelines for optimal performance.Q: What safety features are incorporated in the DIDW Centrifugal Fan?

A: The air-cooled design prevents overheating during continuous operation. The fan is also designed for low noise and comes with reliable, corrosion-resistant materials, ensuring safe and long-term functionality in a variety of operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 140 MM X 150 MM

Price 800 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW Centrifugal Fan

Cooling System : Air Cooling

Dimension (L*W*H) : 140 mm x 150 mm

Material : Mild Steel

DIDW Centrifugal Fan 151 MM X 228 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW Centrifugal Fan

Cooling System : Air Cooling

Dimension (L*W*H) : 151 mm x 228 mm

Material : Mild Steel

DIDW Centrifugal Fan 380 MM X 305 MM

Price 8500 INR

Minimum Order Quantity : 12 Pieces

Product Type : DIDW Centrifugal Fan

Cooling System : Other, Air Cooled

Dimension (L*W*H) : 380 mm x 305 mm (Impeller size)

Material : Mild Steel

DIDW Centrifugal Fan 330 MM X 250 MM

Price 7000 INR

Minimum Order Quantity : 12 Pieces

Product Type : Centrifugal Fan

Cooling System : Air Cooling

Dimension (L*W*H) : 330 MM X 250 MM

Material : Mild Steel

Send Inquiry

Send Inquiry