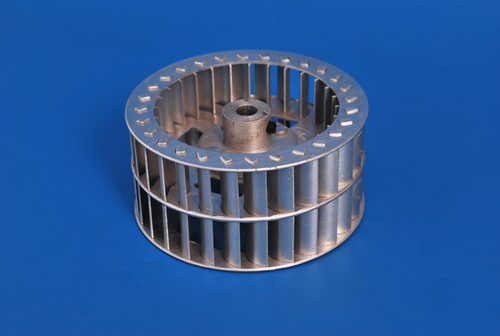

DIDW Centrifugal Fan 300 MM X 203 MM

DIDW Centrifugal Fan 300 MM X 203 MM Specification

- Instruments Type

- Fan/Blower

- Orientation

- Horizontal Mounting

- Efficiency

- Up to 80%

- Automation Grade

- Manual/Standard

- Air Flow

- 3000 m3/hr

- Temperature

- -10C to 60C

- Usage & Applications

- HVAC, Ventilation, Industrial Air Handling, Exhaust Systems

- Measurement

- Air Flow/Volume

- Power Source

- Electric

- Product Type

- Double Inlet Double Width (DIDW) Centrifugal Fan

- Material

- Mild Steel (MS)

- Cooling System

- Air Cooled

- Noise Level

- Less than 80 dB

- Processing Time

- Continuous

- Capacity

- 3000 CFM

- Voltage

- 415 V AC

- Weight

- Approx. 45 kg

- Dimension (L*W*H)

- 300 mm x 203 mm (Fan Housing)

- Surface

- Powder Coated Finish

DIDW Centrifugal Fan 300 MM X 203 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- Main Domestic Market

- All India

About DIDW Centrifugal Fan 300 MM X 203 MM

DIDW Centrifugal Fan 300 MM X 203 MM

DIDW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM & INCH |

|

||

| 48 | ETIP 12 80 | 300 X 203 X 235 | 12 X 8 | 15 MM,20 MM,25 MM & 1 | AL. / GI. |

Exceptional Airflow and Efficiency

Engineered for maximum airflow, this centrifugal fan delivers 3000 m3/hr with efficiency up to 80%. The backward curved 12-blade impeller and belt-driven design ensure robust performance, making it suitable for varied industrial and HVAC applications, including exhaust and ventilation systems. Its deep groove ball bearings and Class F insulation enhance its reliable operation.

Durability and Safety Assured

Manufactured from mild steel and coated with a powder enamel finish, the fan maintains resilience even in tough environments. IP55 protection safeguards against dust and moisture, while its air-cooled system supports sustained use from -10C up to 60C. The deep groove ball bearings further contribute to long-lasting performance and minimal maintenance needs.

FAQs of DIDW Centrifugal Fan 300 MM X 203 MM:

Q: How is the DIDW Centrifugal Fan installed?

A: This fan is base mounted with a horizontal orientation, allowing it to be securely positioned on a stable surface. Its rectangular inlet and outlet enable easy integration into HVAC, ventilation, or industrial ductwork systems.Q: What applications is this centrifugal fan most suitable for?

A: The fan is ideal for HVAC systems, industrial air handling, ventilation, exhaust systems, and any application requiring high-volume airflow up to 3000 CFM in environments ranging from -10C to 60C.Q: When should I consider using a backward curved impeller?

A: A backward curved impeller is preferred when you require high efficiency and stable performance at various static pressures, especially in continuous processing operations that demand lower energy consumption and noise levels.Q: Where can this fan be utilized?

A: This centrifugal fan is suitable for installation in commercial buildings, manufacturing plants, warehouses, and other facilities across India that need robust ventilation and air circulation setups.Q: What is the process for maintaining the fan for optimal performance?

A: Routine maintenance involves inspecting the deep groove ball bearings, checking belt tension, ensuring electrical connections are secure, and keeping the powder-coated housing clean to ensure efficient cooling and long-term durability.Q: How does the fan benefit industrial environments?

A: With high airflow capacity, low noise output, and IP55 protection, the fan creates a comfortable, safe, and efficient workspace by effectively handling ventilation, exhaust, and air circulation needs even during continuous operation.Q: What safety features and protections does this fan include?

A: Equipped with Class F insulation, IP55 protection, and a powder-coated mild steel housing, the fan resists electrical hazards, moisture, and physical wear, while the deep groove ball bearings ensure stable and quiet operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in DIDW Centrifugal Fans Manufacturer in India Category

DIDW Centrifugal Fan 610 MM X 455 MM

Price 21000 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Usage & Applications : Industrial Ventilation, HVAC Systems, Air Handling Units, Dust Extraction

Product Type : DIDW Centrifugal Fan

Cooling System : Other, Air Cooled

DIDW Centrifugal Fan 151 MM X 228 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Usage & Applications : HVAC Systems, Industrial Ventilation, Air Handling Units

Product Type : DIDW Centrifugal Fan

Cooling System : Air Cooling

DIDW Centrifugal Fan 151 MM X 203 MM

Price 900 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Usage & Applications : Ventilation, HVAC, Air Handling Units, Industrial Exhausts

Product Type : DIDW Centrifugal Fan

Cooling System : Other, Air Cooled

DIDW Centrifugal Fan 180 MM X 152 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Usage & Applications : HVAC, Ventilation, Air Handling Units

Product Type : DIDW Centrifugal Fan

Cooling System : Air Cooling

Send Inquiry

Send Inquiry