SISW Centrifugal Blower 610 MM X 150 MM

SISW Centrifugal Blower 610 MM X 150 MM Specification

- Power Source

- Electric

- Orientation

- Horizontal

- Automation Grade

- Semi-Automatic

- Usage & Applications

- Ventilation, Industrial Air Handling, Dust Collection, HVAC

- Air Flow

- Up to 18,000 m/hr

- Efficiency

- Up to 78%

- Temperature

- Ambient to 70C

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 80 dB

- Processing Time

- Continuous

- Capacity

- Custom, typically 5000-20000 m/hr

- Voltage

- 415 V

- Weight

- Approx 75 Kg

- Dimension (L*W*H)

- 610 mm x 150 mm (Wheel Size), housing dimensions as per design

- Surface

- Paint Coated

SISW Centrifugal Blower 610 MM X 150 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Paypal, Cash on Delivery (COD), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

About SISW Centrifugal Blower 610 MM X 150 MM

SISW Centrifugal Blower 610 MM X 150 MM

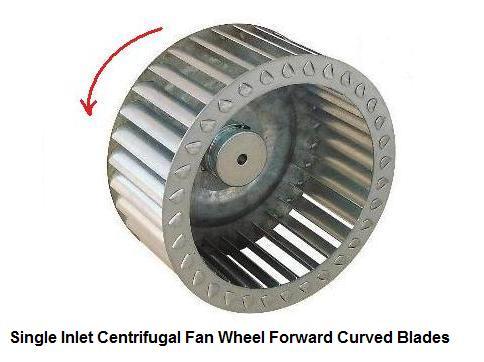

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 38 | ETIP 24 60 | 610 X 150 X 500 | 24 X 6 | 40 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS

Customizable for Diverse Industrial Applications

The SISW Centrifugal Blower is engineered to serve various needs such as HVAC, ventilation, dust collection, and general air handling. With its custom output capacity and static pressure range, it fits perfectly in both small and large-scale projects. Manufacturers offer customization upon request, ensuring the blower aligns closely with specific system requirements. Its heavy-duty design and efficient operation make it suitable for continuous processing environments.

Efficient and Reliable Performance

This centrifugal blower features a dynamically balanced, backward curved impeller with eight blades, optimizing air flow and energy consumption. The belt-driven, base-mounted construction ensures stable mounting, while vibration levels remain within permissible limits. With a maximum efficiency of up to 78% and an air flow capacity up to 18,000 m/hr, the blower provides consistent, reliable performance even under prolonged use in challenging industrial settings.

FAQs of SISW Centrifugal Blower 610 MM X 150 MM:

Q: How does the customization process work for the SISW Centrifugal Blower?

A: Once you share your specific operational requirements such as static pressure, airflow, or motor specifications, the manufacturer evaluates your needs and tailors the blower accordingly. Customization options include pressure range, air flow capacity, and dimensions to suit your system.Q: What are the key benefits of using a backward curved impeller with dynamic balancing?

A: A backward curved impeller improves efficiency and minimizes the risk of overloading under varying conditions. Dynamic balancing ensures smooth, vibration-free operation, leading to longer service life and more silent functioning.Q: When is the SISW Centrifugal Blower best utilized in industrial settings?

A: This blower is ideal for continuous and heavy-duty applications, such as industrial ventilation, HVAC systems, dust collection, and general air handling. Its robust construction makes it suitable for environments requiring reliable, round-the-clock performance.Q: Where can the SISW Centrifugal Blower be installed and used?

A: Designed for base mounting in horizontal orientation, this blower is commonly installed in plant rooms, dust collection systems, manufacturing facilities, and large commercial air handling units across India.Q: What maintenance process is recommended to ensure blower longevity?

A: Periodic inspection of belts, bearings, and impeller cleanliness is vital. Ensure the drive system remains properly tensioned and aligned, and check for abnormal noise or vibration for optimal performance and durability.Q: How does the blower ensure safety and operational stability in continuous use?

A: The blowers heavy-duty, welded construction with corrosion resistance, dynamic balancing, and operation within acceptable vibration limits ensures safe, continuous service. The painted surface finish and mild steel material further protect against adverse conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 330 MM X 150 MM

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Usage & Applications : Industrial ventilation, HVAC systems, Exhaust and Air Handling

Cooling System : Other, Air Cooled

Product Type : SISW Centrifugal Blower

SISW Centrifugal Blower 610 MM X 250 MM

Price 15500 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Usage & Applications : Industrial Ventilation, Air Handling, Dust Extraction

Cooling System : Other, Air Cooled

Product Type : Centrifugal Blower

SISW Centrifugal Blower 165 MM X 100 MM

Price 700 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Usage & Applications : Ventilation, HVAC, Industrial exhaust and air handling systems

Cooling System : Other, Air Cooled

Product Type : SISW Centrifugal Blower

SISW Centrifugal Blower 330 MM X 125 MM

Price 4500 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel (MS)

Usage & Applications : Ventilation, HVAC, Industrial exhaust, Air filtration systems

Cooling System : Other, Air Cooled

Product Type : SISW Centrifugal Blower

Send Inquiry

Send Inquiry