SISW Centrifugal Blower 330 MM X 150 MM

SISW Centrifugal Blower 330 MM X 150 MM Specification

- Efficiency

- High

- Automation Grade

- Manual

- Usage & Applications

- Industrial ventilation, HVAC systems, Exhaust and Air Handling

- Air Flow

- Up to 4500 CFM

- Measurement

- 330 mm x 150 mm

- Temperature

- Ambient to 80C

- Power Source

- Electric

- Instruments Type

- Blower

- Orientation

- Single Inlet, Single Width

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 85 dB

- Processing Time

- Continuous

- Capacity

- Up to 4500 CFM

- Voltage

- 415 V AC

- Weight

- Approx. 75 kg

- Dimension (L*W*H)

- 330 mm x 150 mm

- Surface

- Powder Coated

SISW Centrifugal Blower 330 MM X 150 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Letter of Credit (L/C), Paypal, Cash on Delivery (COD), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Africa, Central America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

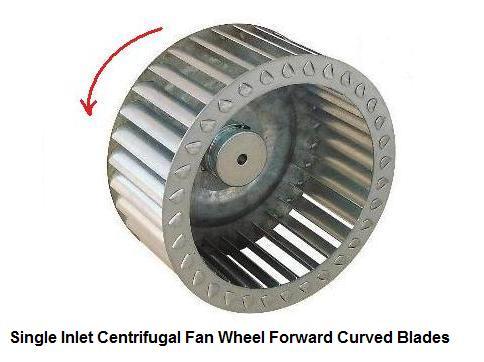

About SISW Centrifugal Blower 330 MM X 150 MM

SISW Centrifugal Blower 330 MM X 150 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 28 | ETIP 13 60 | 330 X 150 X 250 | 13 X 6 | 25 MM & 1 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Robust Construction and Longevity

Built with a 3 mm thick mild steel housing and finished with a powder-coated, anti-corrosive surface, the SISW Centrifugal Blower offers superior resistance against rust and wear. Its durable design ensures reliability even in demanding industrial and HVAC environments, while the base-mounted structure provides stable operation and easy installation.

High Efficiency and User-Friendly Operation

This blower employs a backward-curved impeller with eight blades, optimized for maximum airflow and energy efficiency. Capable of continuous, quiet operation, it meets high-capacity air movement needs up to 4500 CFM. Direct drive ensures minimal maintenance and simplifies control, making it suitable for manual and electric operation alike.

Versatile Applications in Industry

Engineered for single inlet, single width airflow, this blower adapts seamlessly to exhaust, ventilation, and air handling in factories, warehouses, and large commercial spaces. Its compatibility with HVAC systems, industrial process cooling, and general air movement makes it a preferred choice for manufacturers, traders, and wholesalers across India.

FAQs of SISW Centrifugal Blower 330 MM X 150 MM:

Q: How does the SISW Centrifugal Blower 330 MM X 150 MM operate for continuous industrial use?

A: The SISW Centrifugal Blower is designed with a direct drive and air-cooled system, ensuring consistent performance during continuous operation. Its robust construction allows it to efficiently handle demanding tasks such as industrial ventilation, HVAC systems, and air handling processes without interruption.Q: What safety and maintenance measures should be followed for the blower?

A: Routine inspection of the fan housing, impeller, and electrical connections is recommended. The powder-coated, anti-corrosive surface and base-mounted design simplify cleaning and maintenance, while operating under ambient to 80C temperatures ensures thermal safety. Regularly check for obstructions and wear to maintain efficiency and safety.Q: When is this blower ideal to use in industrial applications?

A: This centrifugal blower is ideal for situations requiring high airflow (up to 4500 CFM), such as large-scale ventilation, exhaust systems, air handling, and process cooling, particularly in environments where continuous and efficient operation at moderate noise levels is necessary.Q: Where can the SISW Centrifugal Blower be installed and used?

A: It can be installed in a variety of industrial settingsfactories, commercial complexes, warehouses, and HVAC installations. The base-mounted structure and flanged connection allow for secure, adaptable setup in nearly any industrial air movement or exhaust application.Q: What are the key benefits of using a backward-curved impeller in this blower?

A: The backward-curved impeller design ensures high efficiency and stable airflow, reducing energy consumption and delivering consistent performance. This configuration minimizes clogging and helps maintain a lower noise output compared to alternative designs.Q: How is the SISW Centrifugal Blower supplied and what are the options for buyers in India?

A: Manufacturers, suppliers, traders, and wholesalers across India provide the SISW Centrifugal Blower. Buyers can select specifications based on their capacity, installation, and operational requirements, ensuring optimal performance for their intended applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 230 MM X 90 MM

Price 975 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 230 mm x 90 mm (Blower Size)

Material : Mild Steel

Efficiency : High Efficiency Impeller

Voltage : 220240 V AC

SISW Centrifugal Blower 165 MM X 100 MM

Price 700 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 165 mm x 100 mm (Impeller Size)

Material : Mild Steel

Efficiency : Up to 75%

Voltage : 220240 V

SISW Centrifugal Blower 610 MM X 150 MM

Price 12600 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 610 mm x 150 mm (Wheel Size), housing dimensions as per design

Material : Mild Steel

Efficiency : Up to 78%

Voltage : 415 V

SISW Centrifugal Blower 150 MM X 75 MM

Price 600 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 150 mm x 75 mm (Blower Size)

Material : Mild Steel

Efficiency : High

Voltage : 220240 V

Send Inquiry

Send Inquiry