SISW Centrifugal Blower 150 MM X 75 MM

SISW Centrifugal Blower 150 MM X 75 MM Specification

- Measurement

- Dynamic Pressure/Air Volume

- Automation Grade

- Semi-Automatic

- Efficiency

- High

- Power Source

- Electric

- Usage & Applications

- Industrial Ventilation, Air Handling, Fume Extraction

- Air Flow

- 500-800 CFM

- Orientation

- Single Inlet Single Width (SISW)

- Instruments Type

- Blower

- Temperature

- Ambient

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 75 dB

- Processing Time

- Continuous

- Capacity

- 500-800 CFM

- Voltage

- 220-240 V

- Weight

- 18 kg

- Dimension (L*W*H)

- 150 mm x 75 mm (Blower Size)

- Surface

- Painted

SISW Centrifugal Blower 150 MM X 75 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Domestic Market

- All India

About SISW Centrifugal Blower 150 MM X 75 MM

SISW Centrifugal Blower 150 MM X 75 MM

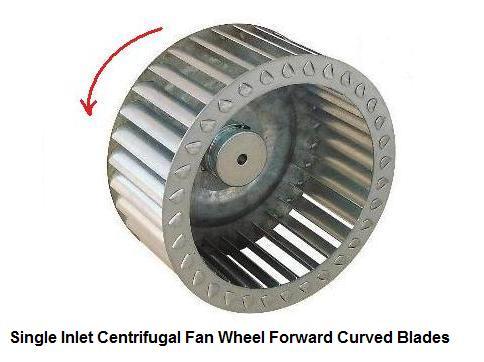

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| OD X HT X ID | OD X HT | MM X INCHES | |||

| 6 | ETIP 6 30 | 150 X 75 X 122 | 6 X 3 | 12.70 MM ( 1/2 ) & 15 MM | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Efficient Industrial Air Handling

Designed for demanding environments, the SISW Centrifugal Blower delivers high-efficiency airflow ranging from 500 to 800 CFM. Its robust mild steel construction and forward-curved impeller make it ideal for industrial ventilation, providing reliable performance while maintaining noise levels below 75 dB. The direct drive and base-mounted configuration ensure stable operation and ease of maintenance.

Precision and Durability for Continuous Use

With a powder-coated finish and Class B insulation, this blower excels in temperature-resilient operation and corrosion resistance. Its eight-blade design and dynamic pressure capability facilitate optimal air movement in fume extraction systems, air handling units, and general industrial usage. The air-cooled system supports continuous processing, delivering unwavering efficiency over extended periods.

Flexible Installation and Integration

Base mounting and rectangular flanged connections streamline the installation process for seamless adaptation to existing industrial setups. The blower is compatible with standard 220-240 V, 50 Hz power sources and conforms to typical automation and measurement protocols, making it a versatile choice for manufacturers, suppliers, and traders nationwide.

FAQs of SISW Centrifugal Blower 150 MM X 75 MM:

Q: How does the SISW Centrifugal Blower enhance industrial ventilation processes?

A: The blower utilizes a forward-curved impeller and high airflow capacity (500-800 CFM) to efficiently remove contaminants, fumes, and excess heat, resulting in improved air quality and regulated temperature within industrial facilities.Q: What are the main benefits of the powder-coated mild steel construction?

A: The powder-coated mild steel body provides excellent durability, corrosion resistance, and longevity, ensuring reliable operation under continuous use and in challenging environments.Q: When should the blower be used in industrial applications?

A: It is ideally used during continuous processing operations whenever robust air movement, fume extraction, or general ventilation is required to maintain a safe and comfortable working environment.Q: Where can the SISW Centrifugal Blower be installed?

A: The blowers base-mounted design and rectangular flanged outlet allow straightforward installation in factories, workshops, laboratories, and any location requiring efficient air handling or extraction systems.Q: What is the process for connecting the blower to existing ductwork?

A: Integration is facilitated through the rectangular flanged outlet, enabling secure and precise connections to standard ductwork systems commonly found in industrial ventilation setups.Q: How does the blowers cooling system affect its performance during prolonged operational periods?

A: Its air-cooled mechanism supports continuous operation by maintaining optimal motor temperature, which improves efficiency and minimizes maintenance requirements.Q: What usage scenarios benefit from the blowers low noise level?

A: Environments that require quiet operation, such as laboratories and clean rooms, benefit from its noise level below 75 dB, creating less disruption while sustaining powerful airflow.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 330 MM X 150 MM

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Other, Air Cooled

Power Source : Electric

Capacity : Up to 4500 CFM

Efficiency : High

SISW Centrifugal Blower 250 MM X 125 MM

Price 1500 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Other, Air Cooled

Power Source : Three Phase AC

Capacity : 2000 CFM

Efficiency : 75%

SISW Centrifugal Blower 610 MM X 200 MM

Price 13500 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Other, Direct Drive

Power Source : Electric

Capacity : Up to 5000 CMH

Efficiency : Up to 75%

SISW Centrifugal Blower 200 MM X 100 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Cooling System : Other, Air Cooled

Power Source : Electric

Capacity : 12001500 CFM (approx)

Efficiency : High

Send Inquiry

Send Inquiry