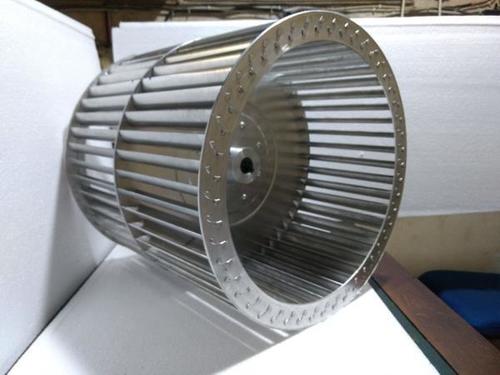

SISW Centrifugal Blower 610 MM X 250 MM

SISW Centrifugal Blower 610 MM X 250 MM Specification

- Temperature

- Ambient

- Air Flow

- 5000 CFM

- Instruments Type

- Blower

- Usage & Applications

- Industrial Ventilation, Air Handling, Dust Extraction

- Automation Grade

- Semi-Automatic

- Efficiency

- High

- Measurement

- 610 mm x 250 mm

- Orientation

- Single Inlet, Single Width (SISW)

- Power Source

- Electric

- Product Type

- Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Low

- Processing Time

- Continuous

- Capacity

- 5000 CFM

- Voltage

- 415 V

- Weight

- Approx. 120 Kg

- Dimension (L*W*H)

- 610 mm x 250 mm

- Surface

- Powder Coated

SISW Centrifugal Blower 610 MM X 250 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Letter of Credit (L/C), Paypal, Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About SISW Centrifugal Blower 610 MM X 250 MM

SISW Centrifugal Blower 610 MM X 250 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 40 | ETIP 24 10 | 610 X 250 X 500 | 24 X 10 | 40 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS

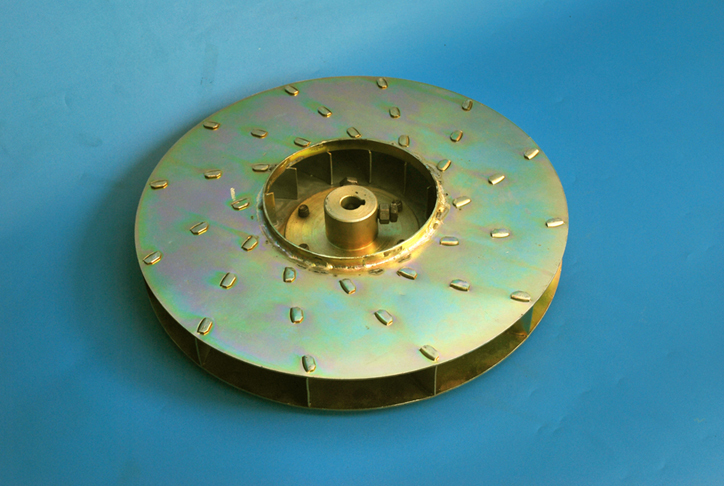

Engineered for Endurance and Efficiency

This blower employs superior componentsincluding an alloy steel shaft and heavy-duty ball bearingsfor consistent, long-lasting operation. With its high-efficiency impeller balanced dynamically and an air-cooled system, the unit performs reliably even during continuous use, making it suitable for challenging industrial environments.

Versatile Applications and Customization

With a customizable inlet and side discharge, the blower suits various industrial applications, including ventilation, dust extraction, and air handling. Its semi-automatic operation and base-mount design allow seamless integration into existing systems, promoting operational flexibility and adaptability.

FAQs of SISW Centrifugal Blower 610 MM X 250 MM:

Q: How is the SISW Centrifugal Blower installed and where is it typically mounted?

A: The blower features a base-mounted design for straightforward installation on stable surfaces in industrial settings. It is commonly placed in ventilation systems, air handling units, or dust extraction setups within manufacturing plants or commercial facilities.Q: What kind of maintenance does the SISW Centrifugal Blower require?

A: Thanks to its robust construction and use of heavy-duty ball bearings, the blower requires minimal maintenance. Routine inspections to ensure proper lubrication and to check for any debris accumulation will help maintain optimal performance.Q: When should this centrifugal blower be used for air handling or dust extraction?

A: This blower is ideal for situations requiring high air volume movement, such as removing airborne particulates or ventilating large spaces. Its 5000 CFM capacity and high static pressure make it suitable for continuous industrial processes and high-demand air handling needs.Q: Where can the blower be customized in terms of inlet size and application?

A: The inlet size of the blower is customizable at the time of order, ensuring compatibility with specific ductwork or equipment configurations. This customization is typically arranged with the manufacturer or supplier prior to production.Q: What process ensures the impellers reliability in this blower?

A: The impeller undergoes dynamic balancing, a process that minimizes vibrations and enhances operational reliability. This leads to quieter functioning and reduced wear on critical components, prolonging equipment lifespan.Q: What are the main benefits of using this blower in industrial applications?

A: Key benefits include high energy efficiency, robust corrosion resistance, low noise output, and the ability to handle continuous operation. The IS 4894 compliant design also assures users of its performance quality and safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 530 MM X 200 MM

Price 12000 INR

Minimum Order Quantity : 12 Pieces

Temperature : Suitable up to 80C air temperature

Noise Level : Below 85 dB

Capacity : 200018000 CFM

Air Flow : 200018000 CFM

SISW Centrifugal Blower 125 MM X 63 MM

Price 500 INR

Minimum Order Quantity : 12 Pieces

Temperature : Ambient up to 60C

Noise Level : Below 75 dB

Capacity : Up to 500 CFM

Air Flow : Up to 500 CFM

SISW Centrifugal Blower 330 MM X 125 MM

Price 4500 INR

Minimum Order Quantity : 12 Pieces

Temperature : Up to 60C

Noise Level : Below 85 dB

Capacity : High volumetric flow

Air Flow : 12001800 m3/hr

SISW Centrifugal Blower 610 MM X 100 MM

Price 12600 INR

Minimum Order Quantity : 12 Pieces

Temperature : Operation up to 80C

Noise Level : < 85 dB

Capacity : Varies as per requirement

Air Flow : 24003500 m3/hr

Send Inquiry

Send Inquiry