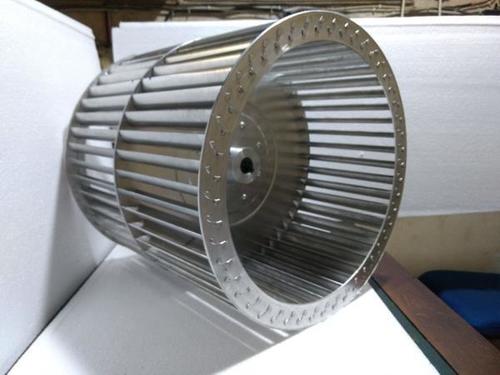

SISW Centrifugal Blower 610 MM X 100 MM

SISW Centrifugal Blower 610 MM X 100 MM Specification

- Efficiency

- Up to 80%

- Orientation

- Horizontal

- Power Source

- Electric

- Usage & Applications

- Industrial ventilation, HVAC, fume extraction, dust collection, air handling units

- Temperature

- Operation up to 80C

- Air Flow

- 2400-3500 m3/hr

- Automation Grade

- Semi-Automatic

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooling

- Noise Level

- < 85 dB

- Capacity

- Varies as per requirement

- Voltage

- 415 V

- Weight

- Approx. 88 kg

- Dimension (L*W*H)

- 610 mm x 100 mm (Impeller Dimensions)

- Surface

- Powder coated/painted

SISW Centrifugal Blower 610 MM X 100 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Letter of Credit (L/C), Delivery Point (DP), Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About SISW Centrifugal Blower 610 MM X 100 MM

SISW Centrifugal Blower 610 MM X 100 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 37 | ETIP 24 40 | 610 X 100 X 500 | 24 X 4 | 40 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Precision-Engineered Airflow

This centrifugal blower is equipped with an 812 blade impeller of 610 mm x 100 mm dimensions, optimized for high performance in demanding environments. The horizontally oriented design and robust construction offer reliable air delivery across industrial processes such as ventilation, fume extraction, and dust collection.

Reliable Operation and Flexible Configuration

Built with insulation class F and powder-coated mild steel, the blower is suitable for operating temperatures up to 80C. Its semi-automatic function and options for direct or belt drive allow integration into diverse systems, making it suitable for manufacturers, suppliers, and traders in industrial sectors.

Efficient and Quiet Performance

With dynamic balancing, the blower maintains stability and low vibration, ensuring a noise level under 85 dB. The efficient air cooling system and up to 80% operational efficiency contribute to energy savings and extended component life, while the base-mounted, flanged design streamlines installation and maintenance.

FAQs of SISW Centrifugal Blower 610 MM X 100 MM:

Q: How is the SISW Centrifugal Blower typically used in industrial applications?

A: The blower is commonly employed for industrial ventilation, HVAC systems, fume extraction, dust collection, and air handling units, delivering controlled airflow and static pressure ideal for various facility requirements.Q: What is the process for installing the SISW Centrifugal Blower?

A: Installation involves positioning the base-mounted blower, securing flanged connections to ductwork, and connecting the unit to a 415 V electrical supply. The choice between direct or belt drive allows adaptability based on site or load requirements.Q: Where can this blower be utilized most effectively?

A: It performs optimally in manufacturing plants, warehouses, processing facilities, and workshops, particularly where efficient air movement and temperature control are crucial to safety and productivity.Q: What are the main benefits of the dynamically balanced impeller construction?

A: Dynamic balancing reduces vibrations, enhances operational stability, decreases wear and tear, and ensures quieter functioning, contributing to longer service life and improved workplace comfort.Q: How do I determine the appropriate configuration and capacity for my needs?

A: Capacity (airflow rate) and configuration (direct or belt drive) should be selected based on specific application requirements, such as desired airflow (24003500 m/hr), available space, and system integration constraints. Consulting with the supplier or manufacturer is recommended for custom solutions.Q: What makes the blower energy efficient and durable?

A: Its up to 80% efficiency, air cooling system, and powder-coated mild steel construction ensure energy savings, protection against environmental factors, and reduced maintenance needs over extended use.Q: When should I opt for a custom color or a specific blade count for the impeller?

A: Custom colors can be chosen for corporate branding or aesthetic preferences, while blade count is selected based on airflow and pressure demands of your specific application, facilitating precise performance tuning.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 530 MM X 150 MM

Price 11500 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : Approx. 800 x 700 x 850 mm

Noise Level : Below 80 dB

Air Flow : 4500 7500 CFM (cubic feet per minute)

Cooling System : Other, Air Cooled

SISW Centrifugal Blower 250 MM X 75 MM

Price 1200 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : Approx. 360mm x 295mm x 330mm

Noise Level : < 80 dB

Air Flow : Upto 2500 m3/hr

Cooling System : Other, Air Cooled

SISW Centrifugal Blower 150 MM X 50 MM

Price 600 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 150 mm x 50 mm (Inlet x Width)

Noise Level : Low

Air Flow : 200400 m/hr

Cooling System : Other, Air Cooled

SISW Centrifugal Blower 150 MM X 100 MM

Price 700 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 400 mm x 320 mm x 310 mm

Noise Level : Below 80 dB

Air Flow : 1200 m/hr

Cooling System : Other, Air Cooled

Send Inquiry

Send Inquiry