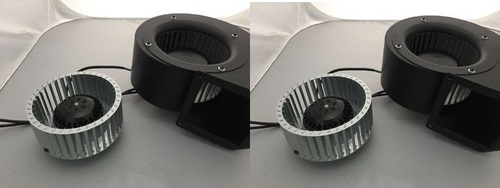

SISW Centrifugal Blower 455 MM X 150 MM

SISW Centrifugal Blower 455 MM X 150 MM Specification

- Power Source

- Electric

- Temperature

- Ambient

- Orientation

- Horizontal

- Automation Grade

- Semi-Automatic

- Efficiency

- Up to 80%

- Air Flow

- 3000-9000 m/hr

- Usage & Applications

- Ventilation, Exhaust, Industrial Air Handling

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 80 dB

- Processing Time

- Continuous

- Capacity

- 3000-9000 m/hr

- Voltage

- 415 V AC

- Weight

- Approx. 55 kg

- Dimension (L*W*H)

- 455 mm x 150 mm (Impeller Size)

- Surface

- Powder Coated

SISW Centrifugal Blower 455 MM X 150 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Main Export Market(s)

- South America, Western Europe, Africa, Central America, Eastern Europe, Middle East, Asia, North America, Australia

- Main Domestic Market

- All India

About SISW Centrifugal Blower 455 MM X 150 MM

SISW Centrifugal Blower 455 MM X 150 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 32 | ETIP 18 60 | 455 X 150 X 365 | 18 X 6 | 35 MM & 1.5 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Robust Construction and Reliable Performance

Crafted from high-quality mild steel and finished with powder coating, the SISW Centrifugal Blower ensures durability in demanding industrial environments. The air-cooled system, belt drive, and floor-mounted design support consistent, continuous operation, enabling dependable performance for ventilation, air handling, and exhaust applications.

Efficient and Quiet Operation

Engineered for efficiency, this blower reaches up to 80% operating efficiency, with air flow capacities of 3,0009,000 m/hr. Its single inlet single width impeller and semi-automatic controls optimize air movement with noise levels kept below 80 dB, supporting comfortable and productive workspaces.

Versatile Applications and Easy Installation

Suitable for factories, workshops, warehouses, and industrial plants, the horizontal, floor-mounted SISW blower is simple to install and integrate with existing ventilation systems. Its moderate weight and compact impeller size facilitate straightforward setup and relocation as needed.

FAQs of SISW Centrifugal Blower 455 MM X 150 MM:

Q: How is the SISW Centrifugal Blower installed in industrial facilities?

A: This blower is designed for floor mounting with a horizontal orientation. The compact impeller size and weight (approximately 55 kg) make it manageable for installation in various industrial settings. Professional installation is recommended to ensure optimal alignment and belt drive operation.Q: What types of industrial applications is this blower suited for?

A: The SISW Centrifugal Blower is ideal for ventilation, exhaust, and air handling in factories, warehouses, process plants, and other industrial facilities requiring continuous air movement and reliable static pressure.Q: When should the SISW Centrifugal Blower be used over other blower types?

A: It is most effective when space requires horizontal, floor-mounted equipment, and when air flow capacities between 3,0009,000 m/hr and static pressures up to 70 mm WG are required. Its single inlet single width configuration is best suited for targeted ventilation tasks.Q: Where is this centrifugal blower manufactured and supplied?

A: This blower is manufactured, supplied, traded, and wholesaled by providers based in India, ensuring availability and technical support across the region.Q: What is the process for maintaining the SISW Centrifugal Blower?

A: Routine maintenance includes inspecting and tightening the belt drive, cleaning the mild steel blades and housing, lubricating motor bearings if necessary, and monitoring noise levels for operational consistency. Regular checks help extend service life and maintain efficiency.Q: How does the blower keep noise levels below 80 dB during operation?

A: Careful engineering of the impeller type, air-cooled system, and overall construction minimizes vibration and sound emissions. The powder-coated mild steel casing further dampens operational noise, maintaining a quieter industrial environment.Q: What benefits does the SISW Centrifugal Blower offer in terms of energy efficiency and performance?

A: With up to 80% operational efficiency and continuous processing capability, this blower maximizes energy usage for sustained air movement. Its sturdy mild steel design and air-cooled system contribute to reliable performance, reduced maintenance, and lower operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 610 MM X 250 MM

Price 15500 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 610 mm x 250 mm

Voltage : 415 V

Product Type : Centrifugal Blower

Efficiency : High

SISW Centrifugal Blower 250 MM X 125 MM

Price 1500 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 250 mm x 125 mm (Impeller Size)

Voltage : 415 V

Product Type : SISW Centrifugal Blower

Efficiency : 75%

SISW Centrifugal Blower 380 MM X 150 MM

Price 5700 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 380 mm x 150 mm (Impeller Size)

Voltage : 415 V AC

Product Type : SISW Centrifugal Blower

Efficiency : Up to 75%

SISW Centrifugal Blower 150 MM X 50 MM

Price 600 INR

Minimum Order Quantity : 12 Pieces

Dimension (L*W*H) : 150 mm x 50 mm (Inlet x Width)

Voltage : 220240V AC

Product Type : Centrifugal Blower

Efficiency : Up to 80%

Send Inquiry

Send Inquiry