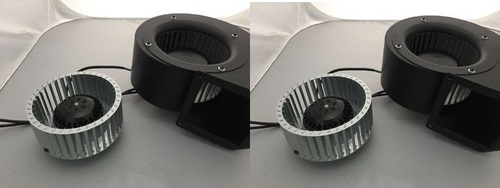

SISW Centrifugal Blower 380 MM X 150 MM

SISW Centrifugal Blower 380 MM X 150 MM Specification

- Usage & Applications

- Ventilation, HVAC, Industrial Air Handling

- Efficiency

- Up to 75%

- Measurement

- Impeller Diameter 380 mm x Width 150 mm

- Automation Grade

- Semi Automatic

- Instruments Type

- Industrial Fan

- Orientation

- Horizontal

- Air Flow

- 4000-5000 m/hr

- Power Source

- Electric

- Temperature

- Ambient to 60 C

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 85 dB

- Processing Time

- Continuous

- Capacity

- 4000-5000 m/hr

- Voltage

- 415 V AC

- Weight

- Approx 95 Kg

- Dimension (L*W*H)

- 380 mm x 150 mm (Impeller Size)

- Surface

- Powder Coated

SISW Centrifugal Blower 380 MM X 150 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Delivery Point (DP), Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Africa, Western Europe, Central America, South America, Asia

- Main Domestic Market

- All India

About SISW Centrifugal Blower 380 MM X 150 MM

SISW Centrifugal Blower 380 MM X 150 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

|

|

OD X HT X ID | OD X HT | MM & INCHES | ||

| 30 | ETIP 15 60 | 380 X 150 X 300 | 15 X 6 | 30 MM & 1.25 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

Versatile Industrial Applications

Designed for high-volume air movement, the blower is effective in ventilation systems, HVAC projects, and industrial environments. Its flexibility in discharge direction and inlet size allows customized integration into various airflow setups, making it suitable for factories, workshops, and warehouses.

Durable Construction & Reliable Performance

Built from mild steel with powder coating, this blower ensures long-term corrosion resistance and stability. Its continuous processing ability and air-cooled system enable reliable performance even in demanding ambient temperatures, with an efficiency of up to 75%.

Ease of Installation and Operation

The base-mounted design simplifies installation, compatible with both direct and belt drive mechanisms, and offers straightforward electrical connectivity on 415 V AC. Semi-automatic controls ensure both ease of operation and consistent air handling output.

FAQs of SISW Centrifugal Blower 380 MM X 150 MM:

Q: How can the SISW Centrifugal Blower be integrated into my factorys ventilation system?

A: This blower is designed for flexible installation using its base-mounted structure. The inlet size and discharge direction can be customized as per your requirements, allowing seamless integration into existing ventilation or HVAC setups in factories, workshops, or warehouses.Q: What are the operational benefits of the backward curved impeller with 8 blades?

A: The backward curved impeller enhances air flow stability and efficiency, providing reduced noise and greater resistance to clogging. Its design supports high capacities (40005000 m/hr) while maintaining a static pressure up to 60 mm WG, which is ideal for industrial air circulation.Q: When is direct drive preferable over belt drive for this blower?

A: Direct drive is recommended for applications requiring lower maintenance and improved efficiency, particularly where precise speed control is not essential. Belt drive offers flexibility for adjusting fan speed or when accommodating specific onsite requirements.Q: Where is this centrifugal blower manufactured and available for supply?

A: The SISW Centrifugal Blower is manufactured and supplied throughout India by certified manufacturers, suppliers, traders, and wholesalers, ensuring broad availability for domestic industrial customers.Q: What process is involved in installing the blower, and what power requirements should be considered?

A: Installation involves securing the blower to a stable base, connecting the appropriate drive system, and wiring to a 415 V AC power source. The unit operates efficiently with a maximum motor power of 3 HP, allowing continuous air handling up to ambient temperatures of 60C.Q: How does the blowers corrosion-resistant, powder-coated finish benefit long-term usage?

A: The powder-coated mild steel surface assures enhanced durability against chemical exposure and humidity, reducing maintenance needs and extending service life in industrial applications where corrosion is a concern.Q: What measurement standards are used for this blower, and why do they matter?

A: The blowers impeller size (380 mm diameter x 150 mm width) adheres to industrial standards for optimal air delivery and consistent performance, ensuring compatibility with a wide range of ventilation and air handling systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 530 MM X 200 MM

Price 12000 INR

Minimum Order Quantity : 12 Pieces

Efficiency : Up to 82%

Weight : Approx. 180 kg

Usage & Applications : Industrial ventilation, Dust Control, HVAC, Fume Extraction

Automation Grade : Manual

SISW Centrifugal Blower 200 MM X 100 MM

Price 950 INR

Minimum Order Quantity : 12 Pieces

Efficiency : High

Weight : Approx. 35 kg

Usage & Applications : Industrial ventilation, dust collection, HVAC, fume extraction

Automation Grade : Manual

SISW Centrifugal Blower 150 MM X 75 MM

Price 600 INR

Minimum Order Quantity : 12 Pieces

Efficiency : High

Weight : 18 kg

Usage & Applications : Industrial Ventilation, Air Handling, Fume Extraction

Automation Grade : SemiAutomatic

SISW Centrifugal Blower 100 MM X 63 MM

Price 450 INR

Minimum Order Quantity : 12 Pieces

Efficiency : Up to 80%

Weight : 28 kg

Usage & Applications : HVAC, Dust Collection, Ventilation, Air Handling

Automation Grade : Semi Automatic

Send Inquiry

Send Inquiry