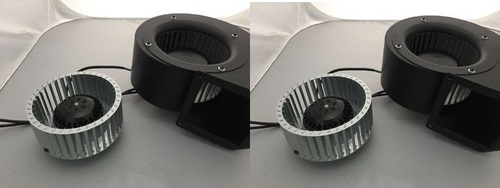

SISW Centrifugal Blower 300 MM X 125 MM

SISW Centrifugal Blower 300 MM X 125 MM Specification

- Usage & Applications

- Industrial Ventilation, HVAC, Exhaust Systems, Air Handling Units

- Instruments Type

- nan

- Air Flow

- 1500-2000 m/h

- Automation Grade

- Semi-Automatic

- Sensor Type

- nan

- Temperature

- Ambient to 60C

- Measurement

- nan

- Scrubber Type

- nan

- Power Source

- Electric

- Display Type

- nan

- Orientation

- Single Inlet, Single Width

- Efficiency

- High Efficiency

- Product Type

- SISW Centrifugal Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Below 75 dB

- Reactor Thickness

- nan

- Processing Time

- nan

- Capacity

- Up to 2000 CFM

- Voltage

- 220-240 V

- Weight

- Approx. 30-40 kg

- Dimension (L*W*H)

- 300 mm x 125 mm (Impeller Size)

- Surface

- Powder Coated

SISW Centrifugal Blower 300 MM X 125 MM Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Letter of Credit (L/C), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About SISW Centrifugal Blower 300 MM X 125 MM

SISW Centrifugal Blower 300 MM X 125 MM

SISW CENTRIFUGAL BLOWER

| SL.NO | CATALOGUE NO | MILLIMETERS | INCHES | BORE SIZE | MATERIAL |

| | OD X HT X ID | OD X HT | MM & INCHES | ||

| 25 | ETIP 12 50 | 300 X 125 X 236 | 12 X 5 | 25 MM & 1 INCHES | AL. / GI. |

ALL BLOWERS ARE STATICALLY & DYNAMICALL BALANCED.

- THE ABOVE MENTIONED PRICES ARE FIXED - NON NEGOTIABLE - BY REQUEST.

- Please describe the bore size , shaft size of Blower accurately in MM or INCHES.

- As per the requirements of blowers, Bore Sizes available are : - Millimeters MM : - 6, 8, 11, 14, 15, 16, 19, 20, 24, 25, 30, 40, 50, 75 & 90 INCHES: - 5/16, 1/2, 5/8, 3/4, 1, 1.5, 2, 3.0, & 3.5

- TERMS AND CONDITIONS APPLY.

- FEEL FREE TO CONTACT US FOR YOUR SPECIAL REQUIREMENTS.

High-Efficiency Industrial Blower

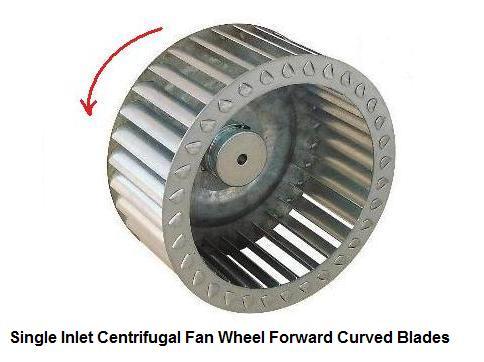

Engineered with a single inlet, single width (SISW) design, this centrifugal blower is equipped with eight backward-curved blades, delivering superior airflow performance for demanding industrial needs. The high-efficiency motor and precision-balanced impeller ensure consistent output while minimizing energy consumption.

Built for Versatility and Durability

Constructed from mild steel with options for MS or aluminium blades and finished with durable epoxy or enamel paint, this blower offers exceptional resistance to corrosion and wear. The direct drive system simplifies maintenance and reduces transmission losses, while customizable discharge positions enhance adaptability across installation requirements.

Ideal Applications and Operational Benefits

The blower is well-suited for use in HVAC systems, air handling units, industrial ventilation, and exhaust setups. Its semi-automatic operation and electric power source ensure ease of integration. With low noise emissions and high airflow, it provides efficient and reliable air movement for clean air requirements in a wide range of working environments.

FAQs of SISW Centrifugal Blower 300 MM X 125 MM:

Q: How is the SISW Centrifugal Blower 300 MM X 125 MM typically used in industrial settings?

A: This blower is primarily utilized for industrial ventilation, HVAC applications, exhaust systems, and air handling units. Its robust airflow and customizable discharge orientation make it suitable for maintaining optimal air quality and temperature control in factories, workshops, and commercial buildings.Q: What materials and finishes are available for the blower and its components?

A: The blower casing is constructed from mild steel, and customers can choose between MS or aluminium for the backward-curved blades. For added durability, options exist for epoxy-coated or enamel-painted finishes, ensuring resistance to environmental wear and corrosion.Q: When should I opt for customizing the discharge position of the blower?

A: Customizing the discharge position (0, 90, 180, or 270) is beneficial when needing to fit the blower into specific layout constraints or ducting configurations. This flexibility allows integration into diverse installation sites, optimizing airflow direction according to system design.Q: Where is the SISW Centrifugal Blower best installed for maximum efficiency?

A: The blower is best base-mounted in areas requiring high-efficiency air movement, such as inlets or outlets of ventilation ducts, air handling units, or exhaust systems. It is suitable for indoor installations, operating efficiently in environments with ambient temperatures ranging up to 60C.Q: What is the process for maintaining this blower?

A: Routine maintenance involves periodically checking the motor, cleaning the impeller, and inspecting the direct drive coupling. The air-cooled design and direct drive mechanism simplify service procedures, minimizing required downtime and ensuring consistent performance.Q: What are the main benefits of using this centrifugal blower model?

A: Key advantages include high efficiency, reliable direct drive operation, low noise emissions (below 75 dB), and customizable setup. Its robust build increases lifespan, while the high airflow capacity meets demanding industrial ventilation and air quality needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SISW Centrifugal Fans Manufacturer in India Category

SISW Centrifugal Blower 380 MM X 150 MM

Price 5700 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Cooling System : Other, Air Cooled

Dimension (L*W*H) : 380 mm x 150 mm (Impeller Size)

Voltage : 415 V AC

SISW Centrifugal Blower 330 MM X 150 MM

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Cooling System : Other, Air Cooled

Dimension (L*W*H) : 330 mm x 150 mm

Voltage : 415 V AC

SISW Centrifugal Blower 300 MM X 150 MM

Price 4200 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel

Cooling System : Air Cooling

Dimension (L*W*H) : 300 mm x 150 mm (Inlet x Outlet)

Voltage : 415 V

SISW Centrifugal Blower 330 MM X 125 MM

Price 4500 INR

Minimum Order Quantity : 12 Pieces

Material : Mild Steel (MS)

Cooling System : Other, Air Cooled

Dimension (L*W*H) : 330 mm x 125 mm (Impeller size)

Voltage : 220240 V

Send Inquiry

Send Inquiry