Oil Water Separator From Coalescer and Separator

Oil Water Separator From Coalescer and Separator Specification

- Flow Rate

- 1000 LPH to 50000 LPH (customizable)

- Capacity

- 500 liters to 20,000 liters (as per design)

- Efficiency (%)

- Up to 99% separation efficiency

- Connecting Type

- Flanged or threaded connections

- Temperature Range

- -10C to 80C

- Filter Type

- Cartridge/Element Type

- Filtration Grade

- Fine

- Cleaning Method

- Manual or automatic backwash

- Media Type

- Coalescing and separating elements

- Pressure

- Design pressure up to 10 bar

- Condition

- New

- Material

- Stainless Steel, Mild Steel (option available)

- Mesh

- Multiple fine mesh layers for enhanced coalescence

- Diameter

- Customized as per requirement (commonly 4 to 20)

- Construction

- Vertical cylindrical shell with access for maintenance

- Medium Filter

- Oil/Water Emulsion

- Weight

- Varies with size (standard: 100800 kg)

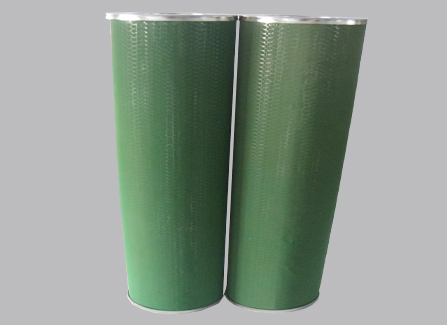

- Shape

- Cylindrical

- Feature

- Efficient separation of oil and water using coalescer and separator element design

Oil Water Separator From Coalescer and Separator Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Africa, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Oil Water Separator From Coalescer and Separator

Oil Water Separator From Coalescer and Separator

We have been doing Oil Water Separator so many years to guarantee Oil Water Separator so just rest assured to choose our In Oil Water Separator.

Category: Coalescer & Separator Tag: Oil Water Separator

Efficient Oil-Water Separation

Utilizing multiple fine mesh layers and high-quality coalescing elements, this separator ensures fine filtration and high separation efficiencyup to 99%. The advanced design reliably addresses oil and water emulsions often found in wastewater streams of refineries, industrial discharges, and fuel handling facilities.

Robust Construction for Enduring Use

Manufactured from stainless steel or mild steel, and protected with powder coating or epoxy paint, this separator is built for longevityeven in harsh environments. Nitrile or Viton gaskets ensure leak-proof performance, and the cylindrical shell offers structural integrity. Maintenance is streamlined with accessible manholes.

Seamless Integration and Versatile Application

Skid-mounted for hassle-free integration, this system suits a wide range of industries. It is compatible with customized capacity, inlet/outlet dimensions, and diameter requirements, catering to applications from 500 up to 20,000 liters capacity and flow rates up to 50,000 LPH.

FAQs of Oil Water Separator From Coalescer and Separator:

Q: How does the Oil Water Separator achieve up to 99% separation efficiency?

A: The separator utilizes coalescing and separating elements with multiple fine mesh layers, which enhance coalescence and promote the gathering of oil droplets for efficient separation from water. This design enables the system to achieve separation efficiencies as high as 99%, even with challenging oil/water emulsions.Q: What are the benefits of the powder-coated or epoxy-painted surface treatment?

A: Powder coating or epoxy painting provides a protective layer that resists corrosion and extends the lifespan of the separator, making it suitable for use in harsh industrial environments, refineries, and wastewater treatment facilities.Q: When should maintenance be performed on the separator?

A: Maintenance schedules depend on operating conditions, but top and side manholes are provided for easy access, allowing for regular inspections and cleaning. The system also offers manual or automatic backwashing options for cleaning the filter elements.Q: Where can this Oil Water Separator be integrated?

A: The skid-mounted and floor-mounted design makes it easy to integrate into both new and existing industrial setups, including oil refineries, fuel depots, industrial wastewater treatment plants, and facilities handling hydrocarbon discharges.Q: What is the process for automatic oil draining in this separator?

A: The separator is equipped with a float mechanism and a level sensor that automatically detect oil accumulation and trigger the oil drain, ensuring consistent operation and minimizing manual intervention.Q: How customizable are the inlet and outlet connections?

A: The inlet and outlet sizes are available from DN40 to DN250, with custom options available, and support both flanged and threaded connections for seamless integration with site-specific piping requirements.Q: What advantages does the bypass arrangement provide?

A: The manual or automatic bypass arrangement allows uninterrupted operation and maintenance by redirecting flows as needed, minimizing downtime and maintaining system efficiency during servicing or unexpected events.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

Basket Strainer From Oil Filter

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel

Condition : New

Feature : High dirt holding capacity, Reusable, Easy installation and removal

Cleaning Method : Other, Manual/Backwash

Construction : Other, Seamless welded joints

EPE Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel / Glass Fiber / Paper

Condition : New

Feature : High dirt holding capacity, corrosion resistance, userfriendly design, long service life

Cleaning Method : Other, Replaceable / Some types washable

Construction : Other, Pleated/Seamless

Parker Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel / Microglass Fiber / Cellulose (varies by model)

Condition : New

Feature : High dirtholding capacity, corrosion resistance, long service life

Cleaning Method : Other, Replaceable / Disposable (not washable)

Construction : Other, Pleated Element

HYDAC Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Glass Fiber, Stainless Steel, Paper

Condition : New

Feature : High Dirt Holding Capacity, Low Pressure Drop, Interchangeable with Original Element

Cleaning Method : Other, Replaceable Element, NonWashable

Construction : Other, Cylindrical, Multilayered

Send Inquiry

Send Inquiry