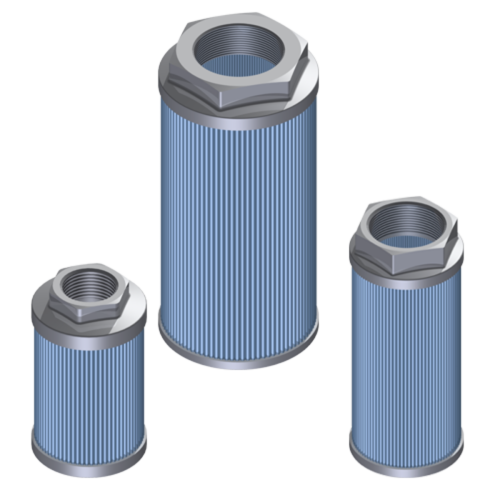

Parker Oil Filter Element From Hydraulic Oil Filters

Parker Oil Filter Element From Hydraulic Oil Filters Specification

- Filtration Grade

- Beta 200 (ISO 16889)

- Media Type

- Microglass / Cellulose / Stainless Steel Wire Mesh

- Connecting Type

- End Caps Buna / Viton / Nitrile Seals

- Efficiency (%)

- 98% at rated micron (typically Beta 200 rating)

- Pressure

- Up to 210 bar (depending on model)

- Flow Rate

- 10200 L/min (varies per element specification)

- Cleaning Method

- Replaceable / Disposable (not washable)

- Temperature Range

- -25C to +110C

- Filter Type

- Return Line / Pressure Filter Element

- Capacity

- Up to 12,000 L (depending on application)

- Condition

- New

- Material

- Stainless Steel / Microglass Fiber / Cellulose (varies by model)

- Mesh

- Fine filtration mesh (commonly 525 micron options available)

- Diameter

- Approx. 3670 mm (varies by model)

- Construction

- Pleated Element

- Medium Filter

- Hydraulic Oil

- Weight

- Approx. 200800 g (varies by size)

- Shape

- Cylindrical

- Feature

- High dirt-holding capacity, corrosion resistance, long service life

Parker Oil Filter Element From Hydraulic Oil Filters Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Central America, Africa, South America, Western Europe, Asia, North America

- Main Domestic Market

- All India

About Parker Oil Filter Element From Hydraulic Oil Filters

Please note all the replacement Parker series oil filter and oil filter elements are produced by us whose quality are great enough to meet your requirement meanwhile own very competitive price which can be used well to replace Parker oil filter and oil filter elements that produced by Parker. Please contact Parker directly in case you need Parker original produced oil filter and oil filter elements.

Categories:Replacement Filter Series, Parker Oil Filter Tags:Oil Filter

Element,Parker Oil Filter Element,Parker Oil Filter,Parker Filter

Advanced Hydraulic Oil Filtration

Parker Oil Filter Elements provide superior particulate capture and protection for hydraulic systems. Ideal for industrial and mobile machinery, these elements utilize fine mesh technology (525 micron options) to safeguard vital components and extend equipment life. Their pleated construction maximizes filter surface area for high dirt-holding capacity and efficient flow.

Built for Durability and Compatibility

Constructed using robust materials such as stainless steel, cellulose, and microglass fiber, Parker filter elements resist corrosion and mechanical stress. They are interchangeable with Parker and other OEM filter housings, simplifying maintenance and replacement across diverse hydraulic systems.

Engineered for Optimal Performance

Certified under international ISO standards, these filters ensure reliable filtration performance, achieving 98% efficiency at the rated micron level (Beta 200). With an operating pressure capacity up to 210 bar and temperature tolerance from -25C to +110C, they meet the rigorous demands of hydraulic operations.

FAQs of Parker Oil Filter Element From Hydraulic Oil Filters:

Q: How is the Parker Oil Filter Element used in hydraulic oil filtration?

A: The filter element is installed as a cartridge or insert within hydraulic systems to remove particulates from hydraulic oil. This helps ensure that critical components remain free from contamination, thereby improving system efficiency and reducing wear.Q: What materials are used in the construction of these filter elements?

A: Depending on the model, filter elements may be constructed from stainless steel, microglass fiber, or cellulose media. End caps are made of aluminum, nylon, or steel, and seals are available in nitrile, Viton, or EPDM for robust performance under various operating conditions.Q: When should I replace the Parker hydraulic oil filter element?

A: Replace the filter element when the pressure drop reaches the manufacturers recommended limit or as indicated by service intervals suggested by your equipment supplier. These elements are designed as replaceable/disposable and are not washable.Q: Where can these filter elements be installed in the hydraulic circuit?

A: They are commonly used as return line or pressure filter elements within hydraulic systems, compatible with both Parker and interchangeable OEM filter housings, ensuring adaptability across a wide range of machinery.Q: What is the filtration efficiency and capacity of the filter element?

A: The elements achieve 98% efficiency at the rated micron (typically Beta 200 as per ISO 16889) and can handle fluids up to 12,000 liters depending on the application. Flow rates range from 10 to 200 L/min, suitable for various hydraulic systems.Q: How does the filters pleated construction benefit hydraulic operations?

A: Pleated construction increases the filtration surface area, thereby enhancing dirt-holding capacity, reducing pressure drop, and extending filter service life for more reliable hydraulic system operation.Q: What are the benefits of choosing Parker Oil Filter Elements for my hydraulic systems?

A: They offer high dirt-holding capacity, excellent corrosion resistance, and a long service life, ensuring equipment reliability and operational efficiency. Their compatibility with various OEM housings and adherence to ISO standards make them a versatile and reliable filtration choice.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

Pleated Candle Filter Element From Oil Filter

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Stainless Steel / Metal (as per requirement)

Feature : High dirt holding capacity, Easy installation, Consistent filtration performance, Pleated design for larger surface area

Diameter : Customized (commonly 40 mm 200 mm)

Shape : Cylindrical / Candle

MP FILTRI Suction Oil Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Stainless Steel, Aluminium

Feature : High dirt holding capacity, easy to install and replace, robust construction, compatible with mineral and synthetic oils

Diameter : Standard: 60 mm 180 mm (custom sizes available)

Shape : Cylindrical

HYDAC Hydraulic Oil Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Stainless Steel / Synthetic Fiber / Glass Fiber

Feature : High dirt holding capacity, robust construction, easy installation, long service life

Diameter : Standard and customized sizes available

Shape : Cylindrical

PALL Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Condition : New

Material : Glass Fiber, Stainless Steel, Cellulose

Feature : High dirt holding capacity, corrosion resistance, easy installation

Diameter : Customizable, typically 50200 mm

Shape : Cylindrical

Send Inquiry

Send Inquiry