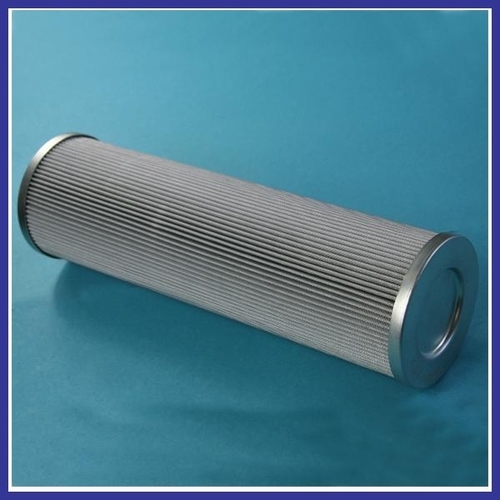

Pleated Candle Filter Element From Oil Filter

Pleated Candle Filter Element From Oil Filter Specification

- Flow Rate

- Customizable (commonly 10 100 LPM)

- Capacity

- As per design requirements

- Connecting Type

- Threaded/Flanged/Customized

- Filtration Grade

- Medium

- Efficiency (%)

- Up to 99%

- Cleaning Method

- Reusable Cleanable by backwashing or ultrasonic cleaning

- Temperature Range

- -10C to +120C

- Filter Type

- Cartridge/Candle Pleated Filter

- Pressure

- Up to 16 Bar (standard)

- Media Type

- Wire Mesh/Non-woven/SS Pleated Media

- Condition

- New

- Material

- Stainless Steel / Metal (as per requirement)

- Mesh

- Customizable (commonly 5 to 200 microns)

- Diameter

- Customized (commonly 40 mm 200 mm)

- Construction

- Pleated Candle Type, Welded/Seamless construction

- Medium Filter

- Oil

- Weight

- Depends on dimensions (typically 300 g - 2 kg)

- Shape

- Cylindrical / Candle

- Feature

- High dirt holding capacity, Easy installation, Consistent filtration performance, Pleated design for larger surface area

Pleated Candle Filter Element From Oil Filter Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Telegraphic Transfer (T/T), Cash Against Delivery (CAD), Cash in Advance (CID)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, South America, Western Europe, Asia, Africa

- Main Domestic Market

- All India

About Pleated Candle Filter Element From Oil Filter

Pleated Candle Filter Element From Oil FilterWe have been doing Pleated Candle Filter Element so many years to guarantee Pleated Candle Filter Element so just rest assured to choose our Pleated Candle Filter Element.

Category: Oil Filter & Oil Filter Element Tags: Oil Purifier, oil filter, Pleated Candle Filter Element

Versatile Construction for Industrial Filtration

Choose between stainless steel, aluminum, or plastic end caps and various seal typesBuna-N, Viton, or EPDMto suit your oil and application. Inner and outer support cages enhance mechanical strength, ensuring durability under varying pressure conditions. The polished or matt surface finish adds versatility, while the pleated structure allows for a generous surface area.

Customizable Dimensions and Filtration Performance

Mesh rating (5200 microns), diameter (40200 mm), and length (up to 40 inches) can be customized to meet your installation and efficiency requirements. Designed for use in hydraulic and lubrication oil systems, these pleated candle elements maintain high filtration performance with a service life typically spanning 612 months.

Reusable and Easy to Maintain

These filter elements are designed for reusability, making maintenance simple by allowing cleaning through backwashing or ultrasonic methods. This reduces downtime and replacement costs compared to disposable filters, supporting sustainable and cost-effective operations.

FAQs of Pleated Candle Filter Element From Oil Filter:

Q: How do I clean and reuse the Pleated Candle Filter Element?

A: This filter element is designed for reusability. It can be cleaned by backwashing with compatible fluid or using ultrasonic cleaning, depending on the contamination level. Always follow the manufacturers recommended cleaning procedure to ensure optimal performance and longevity.Q: What applications are suitable for these filter elements?

A: They are ideal for hydraulic oil filtration, lubrication systems, and industrial oil processing. The filter is suitable for both mineral and synthetic oils, making it versatile across a range of industrial machinery and processes.Q: When should I replace or clean the filter element?

A: Replacement or thorough cleaning is recommended every 612 months, depending on the service conditions and contamination levels. Its important to monitor the pressure drop and operational performance to ensure timely maintenance.Q: Where can I use filters with different end cap and seal materials?

A: End cap materials like stainless steel, aluminum, or plastic, and seal types such as Buna-N, Viton, or EPDM should be selected based on the type of oil and chemical compatibility in your system. Consult your supplier for the most suitable combination for your application environment.Q: What are the main benefits of the pleated candle design?

A: The pleated construction maximizes the filtering surface area, which increases dirt holding capacity and promotes consistent filtration performance. It enables higher flow rates, up to 100 LPM, and ensures efficient removal of contaminants, boosting equipment reliability.Q: How customized can these filter elements be for my system?

A: You can specify mesh micron rating, element length, diameter, surface finish, connection type (threaded/flanged/customized), and even the support cage type. This flexibility ensures compatibility with a variety of industrial filtration setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

EPE Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel / Glass Fiber / Paper

Shape : Cylindrical

Construction : Other, Pleated/Seamless

Condition : New

Diameter : Standard and Custom Options

PALL Filter Cartridge From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Microglass fiber, stainless steel, cellulose

Shape : Cylindrical

Construction : Other, Pleated cartridge

Condition : New

Diameter : Standard and custom sizes available

EPE Hydraulic Oil Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Stainless Steel, Glass Fiber, Paper

Shape : Cylindrical

Construction : Other, Cartridge type, pleated filter element with end caps

Condition : New

Diameter : Customizable, standard options range from 40mm to 180mm

HYDAC Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Material : Glass Fiber, Stainless Steel, Paper

Shape : Round / Cylindrical

Construction : Other, Cylindrical, Multilayered

Condition : New

Diameter : Standard Sizes (Customizable: 50200 mm)

Send Inquiry

Send Inquiry