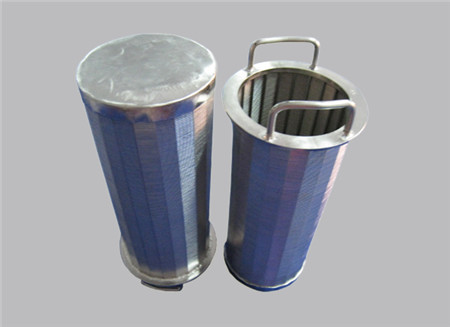

Basket Strainer From Oil Filter

Basket Strainer From Oil Filter Specification

- Media Type

- Liquid/Oil

- Filtration Grade

- Medium

- Temperature Range

- -10°C to 200°C

- Efficiency (%)

- Up to 98%

- Connecting Type

- Flanged/Threaded

- Capacity

- Varies as per requirement

- Flow Rate

- 10 to 800 m³/h (varies by model)

- Filter Type

- Basket Strainer

- Pressure

- Up to 10 bar

- Cleaning Method

- Manual/Backwash

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Wire Mesh

- Diameter

- Customizable (typically 2 to 12)

- Construction

- Seamless welded joints

- Medium Filter

- Oil

- Weight

- Depends on size, approx. 1.5 to 12 kg

- Shape

- Cylindrical basket

- Feature

- High dirt holding capacity, Reusable, Easy installation and removal

Basket Strainer From Oil Filter Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America, Australia

- Main Domestic Market

- All India

About Basket Strainer From Oil Filter

We have been doing Basket Strainer so many years to guarantee Basket Strainer so just rest assured to choose our Basket Strainer.

Efficient Filtration for Demanding Environments

Basket Strainers from Oil Filters are purpose-built for rigorous filtration needs in the oil & gas, petrochemical, chemical, and power sectors. The cylindrical stainless steel baskets capture solid contaminants from liquids, safeguarding downstream equipment and ensuring cleaner process flows. Customizable features accommodate varied operating conditions and ensure compatibility with diverse fluid systems.

Durable Construction & Seamless Maintenance

With mirror or matte polished stainless steel bodies and seamless welded joints, these basket strainers offer superior corrosion resistance and longevity. The removable basket design enables quick manual cleaning or backwashing, while the wire mesh maintains high efficiency and dirt retention. This results in minimized downtime, straightforward replacement, and cost-effective filtration operations.

FAQs of Basket Strainer From Oil Filter:

Q: How do I clean and maintain the Basket Strainer from Oil Filter?

A: The Basket Strainer features a removable basket, allowing for easy manual cleaning. Depending on contamination level and system requirements, you can either take out the basket and wash it or perform backwashing. Routine inspection and prompt servicing help preserve optimum filtration efficiency and long service life.Q: What industries can benefit from using this Basket Strainer?

A: Industries including oil & gas, petrochemicals, chemical processing, and power plants use these strainers to ensure clean oil and liquids. Their robust, corrosion-resistant design is tailored for demanding environments that require the removal of solid particles from various fluids.Q: When should the basket be replaced or cleaned?

A: Cleaning frequency depends on the level of solids in the media and the applications process cycles. Monitor for a noticeable drop in flow rate or an increase in pressure differential to determine cleaning intervals. Replacement is rarely needed due to the baskets reusable stainless steel construction, but excessive damage or clogging may necessitate it.Q: Where can this strainer be installed in my system?

A: The strainers versatility allows installation in either vertical or horizontal pipelines, making it adaptable to existing infrastructure. Connections are available in both flanged and threaded designs to fit a range of system requirements.Q: What are the benefits of using a stainless steel wire mesh basket?

A: Stainless steel wire mesh is highly durable, resists corrosion, and provides excellent filtration efficiencyup to 98%. The wire mesh is reusable, so operational costs are reduced and maintenance is simplified, even in harsh operating conditions.Q: How do I select the correct micron rating for my process?

A: Choose a micron rating based on the size of particles to be removed and process requirements. Offerings range from 25 to 800 microns, with custom configurations available to match specific system needs. Smaller micron values achieve finer filtration, ideal for sensitive applications.Q: What is the installation process for this Basket Strainer?

A: The strainer is supplied in ready-to-install condition. Its compact cylindrical design and customizable diameter allow for straightforward integration into new or existing pipelines. Ensure the correct end connection (flange or thread) and orientation (vertical or horizontal) are selected for your operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

Pleated Candle Filter Element From Oil Filter

Minimum Order Quantity : 12 Pieces

Feature : High dirt holding capacity, Easy installation, Consistent filtration performance, Pleated design for larger surface area

Material : Stainless Steel / Metal (as per requirement)

Condition : New

Flow Rate : Customizable (commonly 10 – 100 LPM)

Parker From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Feature : High dirtholding capacity, Durable construction, Compact design

Material : Stainless Steel

Condition : New

Flow Rate : 25200 L/min (Varies by model)

Internormen Hydraulic Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Feature : High dirt holding capacity, long service life, robust construction, optimized flow rate

Material : Stainless Steel / Microglass Fiber

Condition : New

Flow Rate : Up to 200 L/min (depends on model)

PALL Hydraulic Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Feature : Highperformance filtration, corrosionresistant, long service life

Material : Glass Fiber, Stainless Steel Mesh, Cellulose

Condition : New

Flow Rate : 20400 L/min (varies by model)

Send Inquiry

Send Inquiry