Internormen Hydraulic Filter From Hydraulic Oil Filters

Internormen Hydraulic Filter From Hydraulic Oil Filters Specification

- Capacity

- Depends on size/model

- Filtration Grade

- Fine/Coarse available

- Flow Rate

- Up to 200 L/min (depends on model)

- Filter Type

- Hydraulic Oil Filter

- Pressure

- Max. 210 bar

- Media Type

- Glass Fiber / Cellulose / Stainless Steel

- Efficiency (%)

- Up to 99.9%

- Cleaning Method

- Replaceable cartridge

- Temperature Range

- -30C to +120C

- Connecting Type

- Threaded / Flanged

- Condition

- New

- Material

- Stainless Steel / Microglass Fiber

- Mesh

- Standard/Custom mesh sizes available

- Diameter

- Customizable as per requirement

- Construction

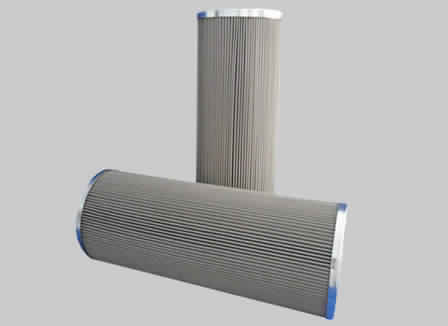

- Pleated Element

- Medium Filter

- Hydraulic Oil

- Weight

- Approx. 850 g (varies by size)

- Shape

- Cylindrical

- Feature

- High dirt holding capacity, long service life, robust construction, optimized flow rate

Internormen Hydraulic Filter From Hydraulic Oil Filters Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Western Europe, Asia

- Main Domestic Market

- All India

About Internormen Hydraulic Filter From Hydraulic Oil Filters

Internormen Hydraulic Filter From Hydraulic Oil Filters

Please note all the replacement Internormen series oil filter and oil filter elements are produced by us whose quality are great enough to meet your requirement meanwhile own very competitive price which can be used well to replace Internormen oil filter and oil filter elements that produced by Internormen. Please contact Internormen directly in case you need Internormen original produced oil filter and oil filter elements.

Categories: Replacement Filter Series, Internormen Filter Tags: Oil Filter Element, Internormen filter, Internormen oil filter, Internormen hydraulic oil filter

Please note all the replacement Internormen series oil filter and oil filter elements are produced by us whose quality are great enough to meet your requirement meanwhile own very competitive price which can be used well to replace Internormen oil filter and oil filter elements that produced by Internormen. Please contact Internormen directly in case you need Internormen original produced oil filter and oil filter elements.

Categories: Replacement Filter Series, Internormen Filter Tags: Oil Filter Element, Internormen filter, Internormen oil filter, Internormen hydraulic oil filter

Unmatched Filtration Flexibility

Select from multiple micron ratings (3, 5, 10, 20, 40) and filtration grades (fine/coarse) to tailor your filters performance precisely to the cleanliness needs of your hydraulic system. Each filter is designed with pleated element technology for extended service intervals and reliable contaminant removal.

Durable Construction and Custom Options

Featuring robust materials such as stainless steel, microglass fiber, and end caps offered in steel or aluminum, these filters are built for longevity and resilience in demanding settings. Customizable diameters, mesh sizes, and colors ensure seamless integration into various industrial hydraulic setups.

Optimized for Versatility

Mountable in inline, tank top, or return line arrangements, these filters accommodate various installation needs. With compatibility for threaded or flanged connections, and available with integrated bypass valves, they are suitable for most hydraulic machinery, offering flexible installation and maintenance.

FAQs of Internormen Hydraulic Filter From Hydraulic Oil Filters:

Q: How do I select the appropriate micron rating for my hydraulic system?

A: The micron rating you choose depends on the specific cleanliness requirements of your equipment. For highly sensitive hydraulic components, a lower micron rating such as 3 or 5 is ideal. For general use where larger particles are less problematic, 10, 20, or 40 micron variants may be suitable. Always consult system guidelines or contact us for expert advice.Q: What materials are available for filter construction and sealing?

A: Our filters are constructed from high-quality stainless steel or microglass fiber media, offering both strength and fine filtration. End caps are crafted from either steel or aluminum for enhanced durability. Sealing materials are available in Nitrile or Viton rubber, accommodating varied temperature and chemical compatibility needs.Q: When should the hydraulic filter cartridge be replaced?

A: The filter should be replaced according to the operating hours recommended by your hydraulic systems manufacturer, or when a noticeable drop in flow rate or increase in system pressure is observed. Most users replace the cartridge when it reaches its dirt holding capacity to ensure optimal performance and protect system components.Q: Where can the Internormen Hydraulic Filter be installed?

A: These filters can be installed in inline, tank top, or return line positions within your hydraulic system, providing flexibility for new installations or retrofitting. They are compatible with most systems that support threaded or flanged connections.Q: What is the process for changing the filter cartridge?

A: To replace the cartridge, first depressurize and drain the hydraulic system if necessary. Remove the filter housing, extract the old cartridge, insert the new element, ensure proper sealing, and secure all components. Finally, repressurize and check for leaks before returning the system to operation.Q: What are the primary benefits of using this hydraulic oil filter?

A: Key benefits include high dirt holding capacity, prolonged service life, robust construction, and up to 99.9% filtration efficiency. This ensures optimal protection of hydraulic components, reduced downtime, lower maintenance costs, and reliable system performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hydraulic Filters Manufacturers Suppliers in India Category

HYDAC Hydraulic Oil Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Construction : Other, Cartridge Filter / SpinOn Type

Connecting Type : Other, Threaded / Flanged

Material : Stainless Steel / Synthetic Fiber / Glass Fiber

Shape : Cylindrical

Temperature Range : 25C to +110C

F5 Bag Filter From High Quality Air Filters

Minimum Order Quantity : 12 Pieces

Construction : Other, Multipocket bag type

Connecting Type : Other, Flange/Frame

Material : Synthetic Fiber

Shape : Rectangular pocket

Temperature Range : Up to 80C

HYDAC Oil Filter Element From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Construction : Other, Cylindrical, Multilayered

Connecting Type : Other, End Cap / Threaded / Flanged

Material : Glass Fiber, Stainless Steel, Paper

Shape : Round / Cylindrical

Temperature Range : 20C to +120C

PALL Hydraulic Filter From Hydraulic Oil Filters

Minimum Order Quantity : 12 Pieces

Construction : Other, Cartridge type, pleated design

Connecting Type : Other, Threaded/Flanged (as per specification)

Material : Glass Fiber, Stainless Steel Mesh, Cellulose

Shape : Cylindrical

Temperature Range : 30C to +120C

Send Inquiry

Send Inquiry