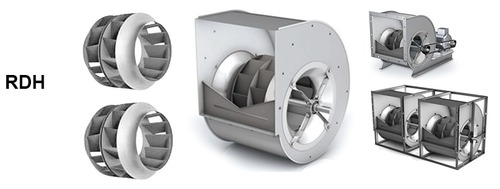

Nicotra Backward Curved Centrifugal Fan RDH 180 R

Nicotra Backward Curved Centrifugal Fan RDH 180 R Specification

- Measurement

- Air Flow Rate

- Automation Grade

- Manual

- Usage & Applications

- Air Ventilation, HVAC Systems, Industrial Air Handling

- Temperature

- -20C to +60C

- Power Source

- Electric

- Orientation

- Horizontal or Vertical

- Instruments Type

- Fan Unit

- Air Flow

- 1150 m/h max.

- Efficiency

- High Efficiency

- Product Type

- Backward Curved Centrifugal Fan

- Material

- Galvanized Steel

- Cooling System

- Air Cooled

- Noise Level

- 65 dB(A)

- Capacity

- Up to 1150 m/h

- Voltage

- 230V / 380V

- Weight

- Approx. 10.5 kg

- Dimension (L*W*H)

- 380 x 285 x 340 mm

- Surface

- Powder Coated

Nicotra Backward Curved Centrifugal Fan RDH 180 R Trade Information

- Minimum Order Quantity

- 1 Piece

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Domestic Market

- All India

About Nicotra Backward Curved Centrifugal Fan RDH 180 R

Nicotra Backward Curved Centrifugal Fan RDH 180 R

Product Benefits

| Product | RDH 180 R |

| Brand | Nicotra |

| Description | Extractor Fan |

| Condition | New |

Find Cheap Spare Parts For Machines Using The Products of Nicotra.Our Team of experts will find the best sales prices for products of Nicotra - RDH 180 R Extractor Fan in USA.Using the products of Nicotra will minimize your costs on spare parts.Our job is to save you time and minimize your expenses on spare parts and industrial components.Our company is not an official distributor of Nicotra, but we are selling their products at competitive prices.Purchase high quality spare parts of Nicotra - RDH 180 R Extractor fan in INDIA on cheap prices.With each day we gain more and more experience and thats why we are able to satisfy your needs for spare parts.You may fill out our Request Form or Send Your Enquiry by E-Mail envirotech76@yahoo.co.in

High-Efficiency Performance

The RDH 180 R centrifugal fan is designed for optimal efficiency, delivering up to 1150 m/h air flow at a static pressure of 640 Pa. Its backward curved impeller design, paired with a modern induction motor and high-quality ball bearings, ensures reliable aerodynamics and reduced energy consumption in HVAC and industrial air movement applications.

Robust Construction and Durable Design

Manufactured with galvanized steel and featuring a powder-coated surface, the RDH 180 R offers impressive durability and corrosion resistance. Its sealed ball bearings and IP54-rated enclosure safeguard internal components from dust and water, making it suitable for demanding operational settings in India.

Flexible Installation and Versatile Application

You can install the RDH 180 R in both horizontal or vertical orientations, accommodating diverse space and airflow requirements. The fan caters to air ventilation, industrial air handling, and other commercial ventilation needs, with manual automation and broad temperature compatibility for year-round use.

FAQs of Nicotra Backward Curved Centrifugal Fan RDH 180 R:

Q: How is the Nicotra RDH 180 R Centrifugal Fan typically installed?

A: This fan is base mounted and can be installed in either a horizontal or vertical orientation. Its compact design (380 x 285 x 340 mm) and manual automation grade allow for flexible positioning to suit different air ventilation setups.Q: What are the main benefits of using a backward curved impeller?

A: The backward curved impeller design provides enhanced efficiency, lower noise levels (65 dB(A)), and stable airflow up to 1150 m/h. This configuration reduces energy consumption and is well-suited for high-pressure air handling in HVAC and industrial systems.Q: When should the Nicotra RDH 180 R be considered for ventilation projects?

A: This fan is ideal for projects requiring high efficiency, durable construction, and reliable air movement in environments ranging from -20C to +60C. Its commonly used in commercial, industrial, and HVAC applications where consistent performance and low maintenance are essential.Q: Where can this centrifugal fan be utilized most effectively?

A: The RDH 180 R is suitable for air ventilation in commercial buildings, factories, and HVAC systems, especially where robust construction and adaptability to various installation positions are required.Q: What is the process for maintaining the RDH 180 R fan?

A: Routine inspection and cleaning of the fan blades and housing are recommended. Since the unit uses sealed ball bearings, they require minimal maintenance compared to open designs, ensuring sustained performance with reduced downtime.Q: What protective features does the RDH 180 R offer?

A: It is equipped with an IP54 protection class to guard against dust and water ingress, Class F insulation for the motor, and a powder-coated galvanized steel casing, maximizing operational safety and extending product life.Q: How does the fan accommodate various power supplies?

A: The RDH 180 R supports both single phase (230V) and three phase (380V) induction motors, operating at a standard frequency of 50 Hz with 2-pole configuration. This flexibility allows integration into a wide range of electrical systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

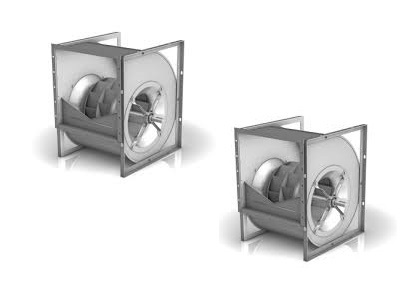

More Products in Series RDH Nicotra Backard Curved Centrifugal Fan Category

Nicotra Backward Curved Centrifugal Fan RDH 710 R

Price 98600 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Cooling System : Other, Air Cooled

Usage & Applications : Industrial ventilation, air handling units, HVAC systems, exhaust and supply air

Product Type : Backward Curved Centrifugal Fan

Nicotra Backward Curved Centrifugal Fan RDH 1120 X1

Minimum Order Quantity : 1 Piece

Voltage : 415 V / 3 Phase / 50 Hz

Cooling System : Other, Air cooled

Usage & Applications : Industrial ventilation, HVAC, process air movement, dust collection

Product Type : Backward Curved Centrifugal Fan

Nicotra Backward Curved Centrifugal Fan RDH 900 K

Price 175000 INR

Minimum Order Quantity : 1 Piece

Voltage : 400 V

Cooling System : Other, Air Cooled

Usage & Applications : Industrial Ventilation, HVAC, Air Handling Units, Clean Rooms

Product Type : Backward Curved Centrifugal Fan

Nicotra Backward Curved Centrifugal Fan RDH 630 R

Price 75000 INR

Minimum Order Quantity : 1 Piece

Voltage : 415 V

Cooling System : Air Cooling

Usage & Applications : HVAC, Industrial Ventilation, Air Handling Units, Process Applications

Product Type : Backward Curved Centrifugal Fan

Send Inquiry

Send Inquiry