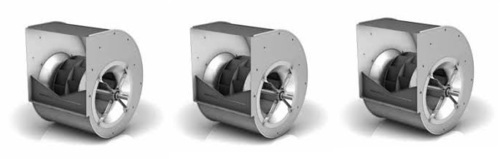

Nicotra Backward Curved Centrifugal Fan RDH 1120 X1

Nicotra Backward Curved Centrifugal Fan RDH 1120 X1 Specification

- Automation Grade

- Manual / Optional automation

- Measurement

- Air volume / static pressure

- Air Flow

- Up to 70,000 m/h

- Orientation

- Horizontal

- Temperature

- Ambient to 80C

- Efficiency

- Up to 85%

- Usage & Applications

- Industrial ventilation, HVAC, process air movement, dust collection

- Instruments Type

- Fan

- Power Source

- Electric

- Product Type

- Backward Curved Centrifugal Fan

- Material

- Heavy gauge galvanized steel / Mild steel

- Cooling System

- Air cooled

- Noise Level

- <85 dB(A) at 1m

- Processing Time

- Continuous

- Capacity

- High (Customized / up to 70,000 m/h)

- Voltage

- 415 V / 3 Phase / 50 Hz

- Weight

- Approx. 300 kg (varies with configuration)

- Dimension (L*W*H)

- Approx. 1400 x 1200 x 1150 mm (varies with configuration)

- Surface

- Powder coated / Galvanized

Nicotra Backward Curved Centrifugal Fan RDH 1120 X1 Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Delivery Point (DP), Letter of Credit (L/C), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Nicotra Backward Curved Centrifugal Fan RDH 1120 X1

Nicotra Backward Curved Centrifugal Fan RDH 1120 X1

Product Benefits

| Product | RDH 1120 X1 |

| Brand | Nicotra |

| Description | Extractor Fan |

| Condition | New |

Find Cheap Spare Parts For Machines Using The Products of Nicotra.Our Team of Experts Will Find the Best Sales Prices For Products of Nicotra - RDH 1120 X1 Extractor Fan in USA.Using the Products of Nicotra Will Minimize Your Costs On Spare Parts.Our Job Is To Save You Time And Minimize Your Expenses On Spare Parts And Industrial Components.Our Company Is Not An Official Distributor of Nicotra, But We Are Selling Their Products At Competitive Prices.Purchase High Quality Spare Parts of Nicotra - RDH 1120 X1 Extractor fan in INDIA on Cheap Prices.With Each Day We Gain More and More Experience and Thats Why We Are Able to Satisfy Your Needs For Spare Parts.You May Fill Out Our Request Form or Send Your Enquiry by E-Mail envirotech76@yahoo.co.in

Engineered for Performance and Reliability

Designed for continuous operation, the RDH 1120 X1 centrifugal fan offers strong airflow and efficient power use. Its backward curved, single-inlet impeller and high-capacity design make it suitable for large-scale industrial tasks. The fan meets stringent safety and protection standards, ensuring durability in challenging environments.

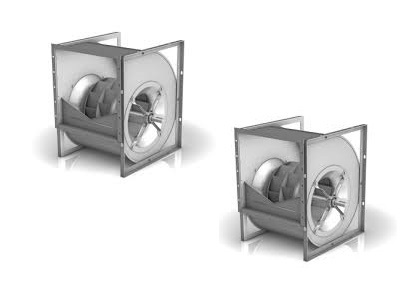

Flexible Installation and Customization

The RDH 1120 X1 fan accommodates a range of installation and operational preferences. With the choice of direct coupled or belt-driven motor mounts, various pole options (4/6), and different automation grades, it adapts to bespoke project requirements. Heavy-duty construction and powder-coated or galvanized surfaces boost longevity and resistance to corrosion.

Ideal Applications Across Industries

This fan is a prime solution for industrial ventilation, HVAC, process air movement, and dust collection systems. Its high capacity and efficiency make it especially valuable for factories, commercial complexes, and other environments where reliable, powerful air movement is essential.

FAQs of Nicotra Backward Curved Centrifugal Fan RDH 1120 X1:

Q: How does the backward curved impeller design benefit industrial ventilation?

A: The backward curved impeller enhances efficiency by reducing turbulence and allowing smoother airflow. This results in higher static pressures (up to 1200 Pa) and increased air volume movement, making it ideal for demanding ventilation and dust collection applications.Q: What are the installation options for the Nicotra RDH 1120 X1 fan?

A: The fan is designed for floor mounting or on a base plate. It supports both direct coupled and belt driven motor configurations, providing flexibility to match your specific setup and application demands.Q: When should this centrifugal fan be used in process applications?

A: Use the RDH 1120 X1 when high airflow and constant operation are crucial, such as in factories, HVAC systems, or industrial process lines that require continuous, reliable air movement up to 70,000 m/h.Q: Where can the RDH 1120 X1 be supplied and installed?

A: This model is available via manufacturer, supplier, trader, and wholesaler channels throughout India. Its robust construction and flexible mounting make it suitable for wide-ranging industrial facilities and commercial premises.Q: What is the process for maintaining the RDH 1120 X1 fan?

A: Routine maintenance is straightforward, since the fan uses sealed-for-life ball bearings and heavy-duty materials. Occasional inspection for dust build-up or surface wear is recommended, but the core components are designed for low-maintenance operation.Q: How does the fans efficiency and noise level enhance its utility?

A: With up to 85% efficiency and noise levels below 85 dB(A) at 1 meter, the fan provides powerful airflow with minimal energy waste and disruption. This makes it a preferable choice for workplaces where efficiency and noise control are priorities.Q: What are the main benefits of using this centrifugal fan in industrial environments?

A: The RDH 1120 X1 offers high customization, robust construction, and reliable, efficient operation for continuous use. Its adaptability and performance ensure optimal environmental control in various settings, from process plants to large commercial spaces.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series RDH Nicotra Backard Curved Centrifugal Fan Category

Nicotra Backward Curved Centrifugal Fan RDH 225 R

Price 21800 INR

Minimum Order Quantity : 1 Piece

Product Type : Backward Curved Centrifugal Fan

Voltage : 230 V / 400 V

Material : Galvanized Steel

Cooling System : Other, Air

Nicotra Backward Curved Centrifugal Fan RDH 1400 X1

Minimum Order Quantity : 1 Piece

Product Type : Backward Curved Centrifugal Fan

Voltage : 415 V / 3 Phase / 50 Hz

Material : Galvanized Steel / Mild Steel

Cooling System : Other, Air Cooled

Nicotra Backward Curved Centrifugal Fan RDH 180 R

Price 17900 INR

Minimum Order Quantity : 1 Piece

Product Type : Backward Curved Centrifugal Fan

Voltage : 230V / 380V

Material : Galvanized Steel

Cooling System : Other, Air Cooled

Nicotra Backward Curved Centrifugal Fan RDH 500 R

Price 49000 INR

Minimum Order Quantity : 1 Piece

Product Type : Backward Curved Centrifugal Fan

Voltage : 415 V

Material : Galvanized Steel

Cooling System : Other, Air Cooled

Send Inquiry

Send Inquiry