Front Mount Differential Pressure Gauge

Front Mount Differential Pressure Gauge Specification

- Thread

- 1/2 BSP

- Sensor Type

- Differential Pressure Sensor

- Bourdon Tube

- Stainless Steel

- Outer Size

- 96mm x 96mm

- Grade

- Industrial

- Display

- Analog

- Seal Material

- Neoprene

- Material

- SS304 Stainless Steel

- Dial Material

- Aluminum

- Pointer Material

- Black Painted Aluminum

- Processing Type

- Machined

- Diameter

- 100mm

- Glass Size

- 100mm

- Mount Type

- Front Mount

- Scale Range

- 0-10 Bar

- Accuracy

- 1% of Full Scale

- Finishing

- Powder Coated

- Measure Pressure Of

- Gas & Liquid

- Accessories

- Mounting Screws, Calibration Certificate

Front Mount Differential Pressure Gauge Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia

- Main Domestic Market

- All India

About Front Mount Differential Pressure Gauge

The Series S1000 Front Mount Differential Pressure Gauge makes panel mounting quick and easy. The S1000 is a diaphragm operated gauge for measuring positive, negative, or differential pressure. The S1000 was designed to allow quick installation saving time and money. This includes easy front mounting with 4 screws without any additional hardware required, and quick tubing connections with molded-in pressure fittings. The Series S1000 Front Mount Differential Pressure Gauge has a span adjustment on the back of the gauge for calibration adjustments. In addition to the time savings offered by the Series S1000 Differential Pressure Gauge, the gauge is based on the same rugged design as the S2000, which allows for years of trouble free operation.

Pressure Limits:

- -20 Hg to 15 PSI (-0.677 bar to 1.034 bar)

- Media Compatibility:

- Air and compatible gasses

- +/- 2% full scale (+/- 3% on -0 and +/- 4% on -00) throughout range at 70 °F (21 °C)

- Temperature Ranges:

- 20 ° to 140 °F (-7 ° to 60C)

- Housing Material:

- Die cast aluminum case with ABS flange and acrylic cover

- Duplicate high and low recessed, push on connections for 3/16 tubing one pair side and one pair back

- Weight:1 lb 2 oz (510 g)

- Accessories:2 connection plugs, 4 mounting screws, 4 screw caps, 2 static pressure connectors, and 3 feet of vinyl tubing

- Agency Approvals: RoHS, CE

Reliable Performance in Harsh Conditions

Designed for industrial use, this differential pressure gauge operates efficiently within -20C to +70C. Its ingress protection rating of IP55 and shatterproof glass provide resilience against environmental factors such as dust and water, ensuring accurate readings even in challenging settings like factories or outdoor installations.

Precision and Durability

With a fine-scale graduation and an accuracy of 1%, the gauge enables precise measurement of gas and liquid pressures. The stainless steel Bourdon tube and machined SS304 body offer superior durability, while the powder coated finish enhances corrosion resistance, making it suitable for long-term continuous operations.

Easy Installation and Maintenance

The gauge features a front mount design and comes with necessary mounting screws for straightforward setup. The annual calibration interval and supplied calibration certificate simplify maintenance, guaranteeing ongoing measurement reliability in hydraulic, filtration, and pump monitoring scenarios.

FAQs of Front Mount Differential Pressure Gauge:

Q: How do I install the front mount differential pressure gauge?

A: The gauge is designed for straightforward front mounting using the supplied screws. Its connection is located at the back side and equipped with a 1/2 BSP thread for easy integration into existing hydraulic or filtration systems.Q: What materials are used in the construction of the gauge, and how does this benefit industrial applications?

A: The case is made of die cast aluminum, with a SS304 stainless steel body and Bourdon tube. The dial and pointer are crafted from aluminum, providing robust protection against corrosion and mechanical stressideal for demanding industrial environments.Q: When should the gauge be calibrated?

A: Annual calibration is recommended for accurate performance. Each gauge is supplied with a calibration certificate, ensuring confidence in its measurements and compliance with industry standards.Q: Where can this differential pressure gauge be used?

A: It is suitable for use in filter monitoring, hydraulic systems, and pump differential measurement, handling both gas and liquid pressure across industrial settings such as factories, plants, and process installations throughout India.Q: What is the gauges overload capacity, and how does it protect the system?

A: The gauge can withstand pressures up to 130% of its full scale (0-10 Bar), safeguarding internal components against accidental user-induced overloads, and maintaining measurement integrity in fluctuating environments.Q: How does the fine graduation scale improve usage in precision monitoring?

A: Fine graduation on a white dial with black markings enables accurate, easy-to-read analog readings. This is particularly beneficial for closely monitoring pressure changes in critical applications where high precision is required.Q: What are the key benefits of the IP55 ingress protection and shatterproof glass?

A: IP55 certification ensures resistance to dust and water ingress, while the shatterproof glass protects the display from impacts, extending the lifespan and reliability of the gauge in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

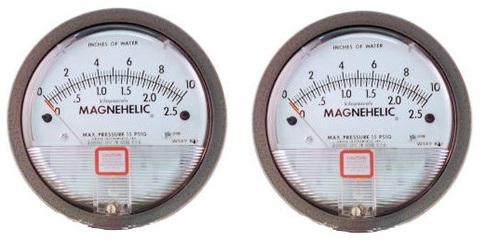

Dwyer 2000-300CM Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Accessories : Two 1/8 NPT Plugs, Mounting Brackets, and Screws

Material : Other, Die Cast Aluminum Case

Sensor Type : Diaphragm Operated

Thread : 1/8 NPT Female

Pointer Material : Other, Red Tapered Pointer

Dwyer USA Model 2150 Magnehelic Gage Range 0-150 Inch WC

Minimum Order Quantity : 12 Pieces

Accessories : Mounting bracket, two 1/8 NPT plugs, three mounting screws, surface mounting hardware, and instruction sheet

Material : Other, Diecast aluminum housing

Sensor Type : Diaphragm

Thread : 1/8 NPT

Pointer Material : Plastic

Dwyer 2010D Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Accessories : Mounting Screws, Two Static Pressure Tips with Tubing

Material : Other, Diecast Aluminum Case

Sensor Type : Mechanical Diaphragm

Thread : 1/8 NPT Female

Pointer Material : Aluminum

Dwyer 2000-0 Magnehelic Gage Range 0-.50 Inch WC

Minimum Order Quantity : 12 Pieces

Accessories : 2 mounting brackets, 2 pipe plugs, 1 twoscrew mounting flange, and selftapping screws

Material : Other, Diecast Aluminum Case, Polycarbonate Lens

Sensor Type : Differential Pressure Sensor

Thread : 1/8 NPT

Pointer Material : Other, Red tipped aluminum

Send Inquiry

Send Inquiry