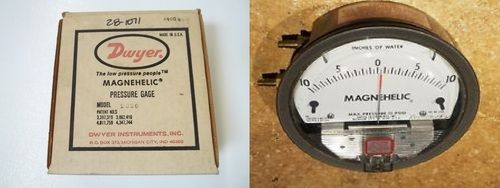

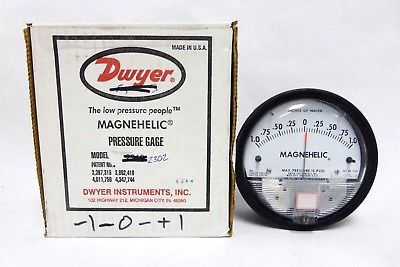

Dwyer USA Model 2302 Magnehelic Gage Range 1-0-1 Inch WC

Dwyer USA Model 2302 Magnehelic Gage Range 1-0-1 Inch WC Specification

- Thread

- 1/8 NPT Female

- Grade

- Industrial

- Outer Size

- 4 inch (approx.)

- Seal Material

- Silicone Rubber

- Display

- Analog

- Sensor Type

- Differential Pressure

- Material

- Die-Cast Aluminum Housing, Acrylic Cover

- Dial Material

- Acrylic

- Pointer Material

- Black Aluminum

- Processing Type

- Precision Instrumentation

- Diameter

- 115 mm (4.5 inch)

- Mount Type

- Surface or Flush Mount

- Scale Range

- 1-0-1 Inch WC (Water Column)

- Accuracy

- 2% of full scale at 70F

- Finishing

- Die-cast aluminum case, gray epoxy finish

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Mounting hardware, two 1/8 NPT plugs, self-tapping screws, plastic tubing, instruction sheet

Dwyer USA Model 2302 Magnehelic Gage Range 1-0-1 Inch WC Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Paypal, Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Middle East, Africa, Western Europe, Central America, Asia

- Main Domestic Market

- All India

About Dwyer USA Model 2302 Magnehelic Gage Range 1-0-1 Inch WC

Dwyer USA Model 2302 Magnehelic Gage Range 1-0-1 Inch WC

Dwyer 2302 Differential Pressure Gage,Range 1-0-1 Inch WC(inches of water),minor divisions.05, calibrated for vertical scale position

Using Dwyer's simple, frictionless Magnehelic gage movement, it quickly indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. It's inexpensive, too.

The Magnehelic gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

What's included with the Dwyer 2302

Dwyer 2302 Magnehelic Differential Pressure Gauge (1-0-1'' w.c.), Vertical Scale

Ask a Question About Dwyer 2302 Magnehelic Differential Pressure Gauge (1-0-1'' w.c.), Vertical Scal

Highly Versatile Pressure Measurement

The Dwyer Model 2302 Magnehelic Gage measures differential air pressure with 2% accuracy, making it suitable for applications such as HVAC system monitoring, filter status checks, and maintaining cleanroom standards. Its compatibility with air and non-corrosive gases enhances its utility in industrial environments.

Built for Durability and Ease of Use

This gage is housed in die-cast aluminum with a gray epoxy finish, providing resilience against demanding conditions. It comes equipped with an acrylic dial, high-contrast analog display, and external zero adjustment screw for straightforward calibration, ensuring prolonged and reliable performance.

Simple Installation and Flexible Mounting Options

Supplied with all necessary mounting accessories, the Magnehelic Gage can be surface or flush-mounted vertically or up to 10 tilt. High and low pressure taps are located on both the side and back, supporting various installation preferences in industrial setups.

FAQs of Dwyer USA Model 2302 Magnehelic Gage Range 1-0-1 Inch WC:

Q: How can I install the Dwyer Model 2302 Magnehelic Gage?

A: Installation is simple: use the provided mounting hardware and accessories to secure the gage either by surface or flush mounting. The unit should be installed vertically, allowing up to a 10 tilt if necessary. Both side and back pressure taps are available for connecting air or non-corrosive gas lines.Q: What applications benefit most from using this Magnehelic gage?

A: This gage is ideal for monitoring air filter status, HVAC performance, cleanroom conditions, and general differential pressure measurement of air and non-corrosive gases in industrial environments, ensuring system efficiency and compliance with standards.Q: When should I use the zero adjustment screw?

A: Use the external zero adjustment screw during installation or whenever you notice the pointer is off zero while under zero pressure conditions. This ensures accurate readings and optimal performance throughout the lifespan of the gage.Q: Where are the pressure connections located on the device?

A: The Model 2302 features high and low pressure taps on both the side and back, using 1/8 NPT female threads. This dual-placement allows flexible tubing arrangements and easier adaptation to system requirements.Q: What is the process for reading pressure values on the Magnehelic gage?

A: Simply observe the analog pointer on the acrylic dial; it indicates the current differential pressure in inches of water column (WC), ranging from 1 to -1. Readings are nearly instantaneous due to the gages fast response time.Q: What are the main benefits of using the Dwyer Model 2302 Magnehelic Gage?

A: The key advantages include reliable accuracy (2% full scale), fast response, robust construction, straightforward installation, and suitability for various industrial pressure monitoring tasks involving air and non-corrosive gases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Finishing : Other, Clear plastic front, black ABS enclosure

Processing Type : Other, Factory Calibrated

Pointer Material : Other, Blackoxide coated aluminum

Mount Type : Other, Surface or flush mount

Dwyer 2000-OOD Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Finishing : Other, Matte Silver Anodized

Processing Type : Other, Mechanical

Pointer Material : Other, Black Tapered Aluminum

Mount Type : Other, Surface or Flush Mounting

Dwyer USA Model 2320 Magnehelic Gage Range 10-0-10 Inch WC

Minimum Order Quantity : 12 Pieces

Finishing : Other, Black anodized aluminum housing

Processing Type : Other, Machined housing with cast aluminum back

Pointer Material : Other, Red adjustable pointer (aluminum)

Mount Type : Other, Surface or flush mount

Dwyer 2000-750PA Magnehelic Differential Pressure Gauge

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Finishing : Other, Textured black finish housing

Processing Type : Other, Mechanically Gasketed

Pointer Material : Aluminum

Mount Type : Other, Surface or Flush Mount

Send Inquiry

Send Inquiry