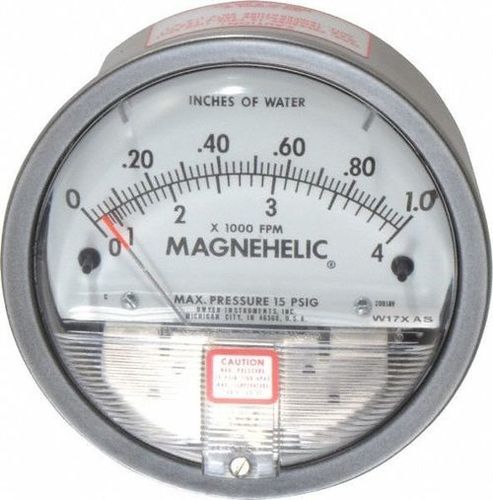

Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge

Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge Specification

- Seal Material

- Silicone rubber

- Bourdon Tube

- Not Applicable (Uses diaphragm sensing element)

- Display

- Analog

- Sensor Type

- Differential Pressure Sensor

- Grade

- Industrial Grade

- Thread

- Standard 1/8 NPT Female Connections

- Outer Size

- Approximately 4.78 inch diameter (121.4 mm)

- Material

- Case: Die cast aluminum, Cover: clear acrylic

- Dial Material

- White aluminum with black and red markings

- Pointer Material

- Black-oxide coated aluminum

- Processing Type

- Factory Calibrated

- Diameter

- 4.78 inch (121.4 mm)

- Glass Size

- 4 inch (approximate viewing window diameter)

- Mount Type

- Surface or flush mount

- Scale Range

- 0-1 kPa

- Accuracy

- 2% of full scale

- Finishing

- Clear plastic front, black ABS enclosure

- Measure Pressure Of

- Air and non-corrosive gases

- Accessories

- Mounting hardware, two 1/8 NPT plugs, two 1/8 NPT pipe thread to rubber tubing adapters, three self-tapping mounting screws

Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Western Europe, Central America, Africa, Asia, North America

- Main Domestic Market

- All India

- Certifications

- YAS

About Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge

Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge

Dwyer 2300-1KPA MAGNEHELIC, DIFFERENTIAL PRESSURE GAUGE, 0.5-0-0.5

- Precision litho-printed scale is accurate and easy to read.

- Red tipped pointer of heat treated aluminum tubing is easy to see. It is rigidly mounted on the helix shaft.

- Pointer stops of molded rubber prevent pointer over-travel without damage.

- "Wishbone" assembly provides mounting for helix, helix bearings and pointer shaft.

- Jeweled bearings are shock-resistant mounted; provide virtually friction-free motion for helix. Motion damped with high viscosity silicone fluid.

- Zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness.

- Helix is precision made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the magnetic field to move the pointer across the scale.

- Samarium Cobalt magnet mounted at one end of range spring rotates helix without mechanical linkages.

- Calibrated range spring is flat spring steel. Small amplitude of motion assures consistency and long life. It reacts to pressure on diaphragm. Live length adjustable for calibration.

- Silicone rubber diaphragm with integrally molded O-ring is supported by front and rear plates. It is locked and sealed in position with a sealing plate and retaining ring. Diaphragm motion is restricted to prevent damage due to overpressures.

- Die cast aluminum case is precision made and iridite-dipped to withstand 168 hour salt spray corrosion test. Exterior finished in baked dark gray hammerloid. One case size is used for all standard pressure options, and for both surface and flush mounting.

- Blowout plug of silicone rubber protects against overpressure on 15 psig rated models. Opens at approximately 25 psig.

- O-ring seal for cover assures pressure integrity of case.

What's included with the Dwyer 2300-1KPA

- Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge (0.5-0-0.5 kPa)

Precision Differential Pressure Measurement

The Dwyer 2300-1KPA uses a sensitive diaphragm sensing element to deliver accurate differential pressure readings across a 0-1 kPa scale, achieving 2% full-scale accuracy. This ensures dependable monitoring of air and non-corrosive gas pressures, critical in industrial processes such as filter efficiency checks, airflow control, and HVAC system diagnostics. Its clear analog display is designed for easy reading in challenging environments.

Durability and Easy Installation

Engineered for rigorous industrial use, this gauge features a robust die-cast aluminum case and a clear plastic front for long-term reliability. Its IP52 rated for dust and light moisture resistance and operates in temperatures from -7C to +60C. The supplied mounting accessories, including adapters and self-tapping screws, simplify both surface and flush installation to suit varied applications.

Factory Calibrated and Hassle-Free Maintenance

Each unit is factory calibrated and ready for installation upon delivery. The external zero adjustment screw allows quick recalibration on-site, ensuring consistent accuracy over the gauges lifespan. Designed with user convenience in mind, the gauge requires minimal maintenance, featuring a non-applicable Bourdon tube replaced by a more stable diaphragm system.

FAQs of Dwyer 2300-1KPA Magnehelic Differential Pressure Gauge:

Q: How is the Dwyer 2300-1KPA Magnehelic gauge installed?

A: The Dwyer 2300-1KPA can be installed using the supplied mounting hardware for surface or flush mounting. Standard 1/8 NPT female ports accommodate pressure connections, and adapters are included for use with rubber tubing, making integration into existing systems straightforward.Q: What types of media can this differential pressure gauge measure?

A: This gauge is designed to measure the differential pressure of air and non-corrosive gases only. Using it to monitor corrosive or liquid media may compromise its performance and safety.Q: When should I use the external zero adjustment screw?

A: Utilize the external zero adjustment screw if the displayed reading drifts from zero when there is no pressure differential across the ports. Regular checks and adjustments help maintain measurement accuracy, especially after extended use or system maintenance.Q: Where is the Dwyer 2300-1KPA typically applied?

A: Common applications include filter condition monitoring, air velocity measurement, airflow control in ventilation systems, and fan or blower pressure monitoring, particularly in industrial and commercial HVAC settings.Q: What is the process for recalibrating this gauge?

A: The gauge comes factory calibrated. For recalibration, use the external zero adjustment screw with the gauge depressurized to set the pointer exactly to zero. For full certification or significant recalibration, return the unit to an authorized service center.Q: How does the IP52 rating benefit users?

A: The IP52 ingress protection indicates resistance to dust and light drops of water, which protects the gauges internal components and enhances reliability in humid or moderately dusty environments.Q: What are the main usage and operational advantages of this gauge?

A: Its analog display delivers instant readings with 2% accuracy, the diaphragm sensing element ensures stability, and overpressure protection up to 10 psi guards against accidental surges. Quick adjustment and minimal maintenance reduce downtime, making it beneficial for continuous process monitoring.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2005-AV Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Outer Size : 110 mm Diameter Approx.

Accessories : Mounting screws, plastic tubing, two 1/8 NPT plugs provided

Glass Size : Not Applicable (Acrylic Window)

Scale Range : 0500 Pa (Pascals)

Accuracy : 2% of full scale

Dwyer 2300-10CM Magnehelic Differential Pressure Gauge Range 5-0-5 CM

Minimum Order Quantity : 12 Pieces

Outer Size : Approximately 4 inch diameter housing

Accessories : Two 1/8 NPT plugs, two 1/8 pipe thread to rubber tubing adapters, three mounting adapters, and screws

Glass Size : Clear acrylic lens

Scale Range : 505 cm of water column (CMWC)

Accuracy : 2% of full scale

Dwyer 2001-AV Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Outer Size : 4inch (standard housing)

Accessories : Two 1/8 NPT plugs, rubber tubing, mounting screws, and surface mounting bracket

Glass Size : 3.75 inches approx.

Scale Range : 01 inch H2O

Accuracy : 2% of full scale

Dwyer USA Magnehelic Gauges 0 To 200 MM WC

Outer Size : Approximately 4 inches Diameter

Accessories : Mounting Bracket, Two Static Pressure Tips, Three 1/8 NPT Plugs, and Screws

Glass Size : Full View Acrylic Lens (Integral with gauge face)

Scale Range : 0 to 200 mm WC

Accuracy : 2% of Full Scale

Send Inquiry

Send Inquiry