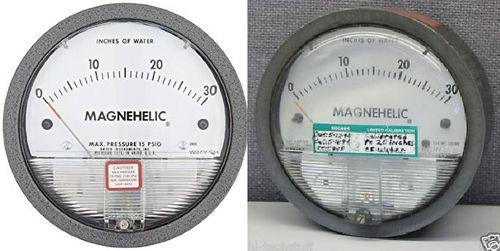

Dwyer USA Magnehelic Gauges 0 To 200 MM WC

Dwyer USA Magnehelic Gauges 0 To 200 MM WC Specification

- Bourdon Tube

- Not Applicable (uses diaphragm sensing element)

- Sensor Type

- Differential Pressure Sensor

- Seal Material

- Silicone Rubber

- Display

- Analog Display

- Thread

- 1/8 NPT Female Connection

- Outer Size

- Approximately 4 inches Diameter

- Grade

- Industrial Grade

- Material

- Die-cast Aluminum Case with Acrylic Lens

- Dial Material

- Plastic with Printed Markings

- Pointer Material

- Aluminum

- Processing Type

- Factory Assembled

- Diameter

- 4 inches (101.6 mm)

- Glass Size

- Full View Acrylic Lens (Integral with gauge face)

- Mount Type

- Surface or Flush Panel Mount

- Scale Range

- 0 to 200 mm WC

- Accuracy

- 2% of Full Scale

- Finishing

- Textured Finish with Durable Acrylic Exterior

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Mounting Bracket, Two Static Pressure Tips, Three 1/8 NPT Plugs, and Screws

Dwyer USA Magnehelic Gauges 0 To 200 MM WC Trade Information

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- Main Domestic Market

- All India

About Dwyer USA Magnehelic Gauges 0 To 200 MM WC

Dwyer USA Magnehelic Gauges 0 To 200 MM WC

INCLUDES

Two 1/8" NPT plugs, two 1/8" rubber tubing adapters, and three mounting adapters with screws

MORE ABOUT THIS ITEM

The Magnahelic guage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems, and pressures in fluid amplifier or fluidic systems. The gauge's motion is damped with high-viscosity silicone fluid. The zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness. Rugged design resists shock, vibration, and overpressure.

The helix is precision-made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the maganetic field to move the pointer across the scale. The samarium cobalt magnet is mounted at one end of the range spring and rotates the helix without mechanical linkages.

Specifications & Description

| Accuracy | ±2% full-scale |

| Dial Size (in) | 4 |

| Dial Size (mm) | 102 |

| Min Pressure (in WC) | 0 |

| Max Pressure (in WC) | 10 |

| Wetted Materials | Aluminum |

| Case | Aluminum |

| Lens Material | acrylic |

| Process Connection | 1/8" NPT |

| Unit Of Measurement | " WC |

| Display | analog dial |

| Media Compatibility | Gases and liquids compatible with wetted materials |

| Resolution | 0.20 |

| Description | Magnehelic Differential Pressure Gauge, Type , 0 to 200 MM WC |

Superior Accuracy and Durability

The Magnehelic Gauge guarantees accuracy within 2% of full scale, ensuring reliable pressure measurements even in demanding industrial settings. Constructed from high-quality die-cast aluminum with a textured finish, it withstands tough conditions and frequent handling. Its durable acrylic lens and silicone rubber seals provide robust protection against dust and water, making it suitable for environments requiring IP56-level enclosure safeguarding.

Flexible Mounting and Easy Installation

Engineered for convenience, this gauge can be surface or flush panel mounted, adaptable to different installation requirements. The vertical orientation is standard, but the design allows calibration for alternate positions if needed. Accessories such as the mounting bracket, pressure tips, and screws ensure installation is swift and secure, reducing downtime during setup in industrial facilities.

Precise Monitoring and User-Friendly Operation

Featuring a clear analog display with integral lens, the Magnehelic gauge allows quick and easy readings at a glance. An external zero adjustment screw simplifies recalibration, helping maintain accuracy over time. The device is maintenance-friendly and designed for continual monitoring of air and non-corrosive gas pressure differentials, supporting safe and efficient process management.

FAQs of Dwyer USA Magnehelic Gauges 0 To 200 MM WC:

Q: How do I install the Dwyer Magnehelic Gauge Model 2000-200 MM WC?

A: This gauge can be mounted in a vertical position as standard, using the included mounting bracket and screws. For other orientations, recalibration is possible to maintain accuracy. Both surface and flush panel mounting are supported, and pressure tips and plugs are provided for straightforward connection to your process lines.Q: What types of media can this Magnehelic gauge measure?

A: The gauge is specifically designed to measure the differential pressure of air and non-corrosive gases only. It is not suitable for liquids or corrosive gas applications, ensuring longevity and reliable operation in approved environments.Q: When should I use the external zero adjustment screw?

A: The external zero adjustment screw should be used whenever the gauge needs recalibration to ensure accurate readings. It is especially useful after installation, repositioning, or in case the gauge experiences impacts that could affect the zero reference point.Q: Where can the Magnehelic gauge be employed in an industrial setting?

A: This device is ideal for use in HVAC systems, clean rooms, filter monitoring, pneumatic conveying, and other industrial applications where monitoring low-pressure air or non-corrosive gases is vital. Its IP56 enclosure makes it suitable for installations where resistance to dust and water ingress is required.Q: What are the benefits of using this differential pressure gauge?

A: The main benefits include accurate, stable, and easy-to-read analog pressure measurements, durable construction for long service life, external zero adjustment for ongoing accuracy, and flexible mounting options to fit diverse industrial requirements.Q: How does the calibration process work for other mounting positions?

A: If mounting the gauge in a non-vertical orientation, calibration should be performed to adjust for any positional effects on accuracy. This is achieved using the external zero adjustment, with reference to a known pressure standard, ensuring continued precision in measurement.Q: What accessories are included with this Magnehelic gauge?

A: Each gauge is supplied with a mounting bracket, two static pressure tips, three 1/8 NPT plugs, and the necessary screws, providing you with all tools needed for standard installation and connection to your system.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer USA Model 2030 Magnehelic Gage Range 0-30 Inch WC

Minimum Order Quantity : 12 Pieces

Dial Material : Other, Aluminum with matte finish

Grade : Industrial Grade

Outer Size : 41/2 inch (114 mm) diameter

Mount Type : Other, Surface or Flush Mount

Scale Range : 030 Inch WC (Water Column)

Dwyer USA Model 2012 Magnehelic Gage Range 0-12 Inch WC

Minimum Order Quantity : 12 Pieces

Dial Material : Other, Acrylic (clear lens)

Grade : Industrial Grade

Outer Size : 4.75 inch diameter (approx. 120 mm)

Mount Type : Other, Surface or flush mount

Scale Range : 012 Inch WC (Water Column)

Dwyer USA Model 2201 Magnehelic Gage Range 0-1 PSI

Minimum Order Quantity : 12 Pieces

Dial Material : Other, Acrylic

Grade : Industrial

Outer Size : Approx. 4 inches diameter

Mount Type : Other, Surface or flush mounting

Scale Range : 01 PSI

Dwyer 2000-00N Magnehelic Gage Range .05-0-.20 Inch WC

Minimum Order Quantity : 12 Pieces

Dial Material : Other, White aluminum with black markings

Grade : Industrial

Outer Size : 4 inch (101.6 mm) diameter

Mount Type : Other, Surface or Flush Panel Mount

Scale Range : .050.20 Inch WC

Send Inquiry

Send Inquiry