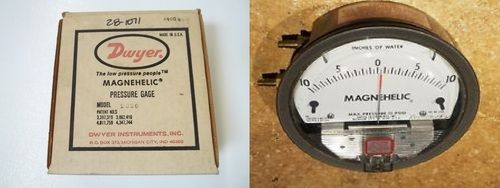

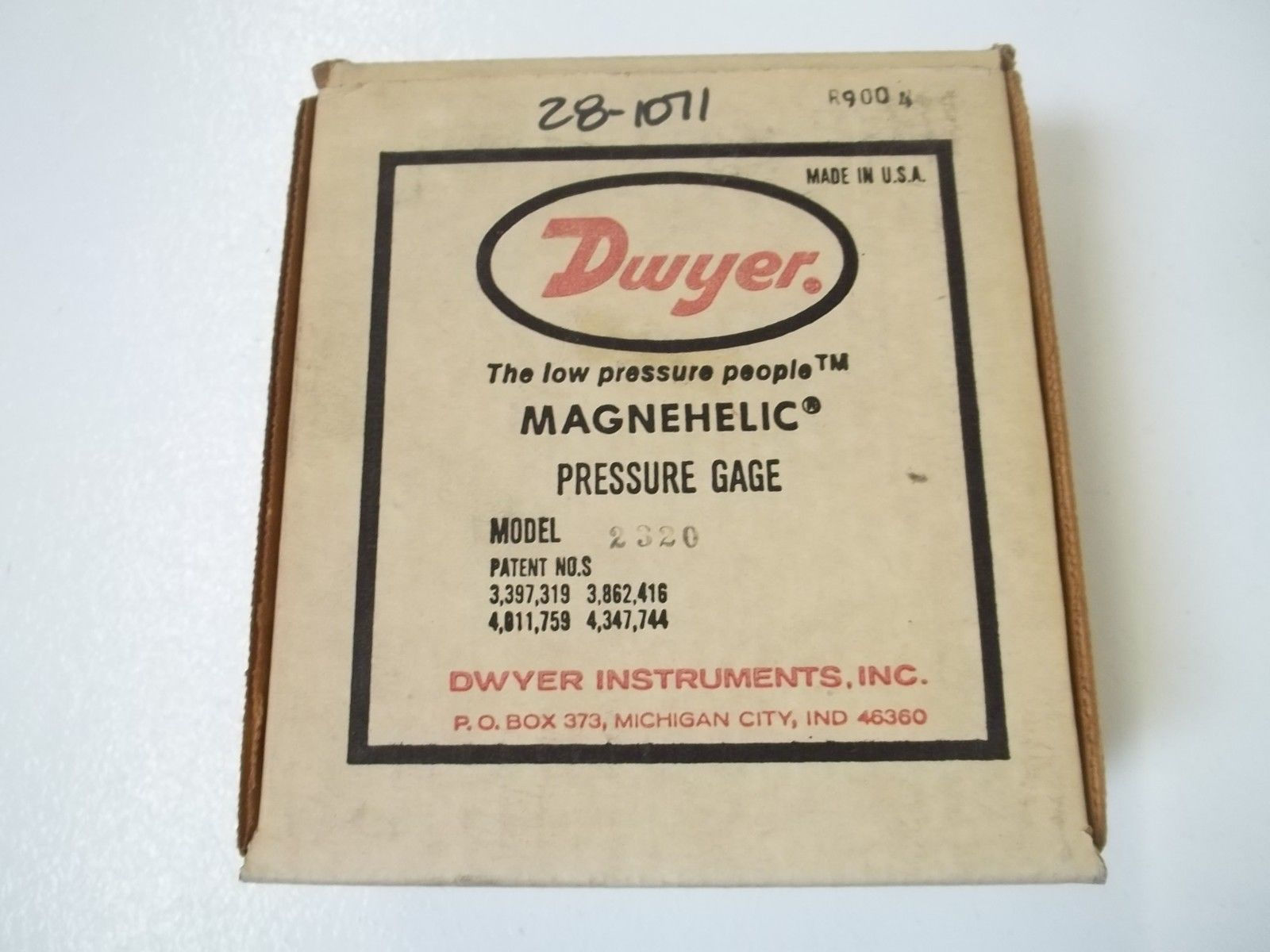

Dwyer USA Model 2320 Magnehelic Gage Range 10-0-10 Inch WC

Dwyer USA Model 2320 Magnehelic Gage Range 10-0-10 Inch WC Specification

- Sensor Type

- Diaphragm

- Bourdon Tube

- Not Applicable (Diaphragm Mechanism)

- Display

- Analog

- Outer Size

- 4 inch (101.6 mm) diameter case

- Thread

- 1/8 NPT

- Grade

- Industrial

- Seal Material

- Silicone rubber

- Material

- Die-cast aluminum case, polycarbonate front

- Dial Material

- White coated aluminum

- Pointer Material

- Red adjustable pointer (aluminum)

- Processing Type

- Machined housing with cast aluminum back

- Diameter

- 4 inch

- Glass Size

- 4 inch (clear acrylic window)

- Mount Type

- Surface or flush mount

- Scale Range

- -10 to 0 to +10 inch WC

- Accuracy

- 2% of full scale

- Finishing

- Black anodized aluminum housing

- Measure Pressure Of

- Low differential air and non-corrosive gases

- Accessories

- 2 mounting brackets, screws, and instruction manual

Dwyer USA Model 2320 Magnehelic Gage Range 10-0-10 Inch WC Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Telegraphic Transfer (T/T), Paypal, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Dwyer USA Model 2320 Magnehelic Gage Range 10-0-10 Inch WC

Dwyer USA Model 2320 Magnehelic Gage Range 10-0-10 Inch WC

Bezel Provides Flange For Flush Mounting in Panel. Clear Plastic Face is Highly Resistant to Breakage.Provides Undistorted Viewing of Pointer and Scale.

Dwyer 2320 Differential Pressure Gage, Range 10-0-10 Inch WC (inches of water), minor divisions .050, calibrated for vertical scale position

Using Dwyer's simple, frictionless Magnehelic gage movement, it quickly indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. It's inexpensive, too.

The Magnehelic gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

What's included with the Dwyer 2320Dwyer 2320 Magnehelic Differential Pressure Gauge (10-0-10 Inch w.c.), Vertical Scale

Robust Build for Industrial Applications

Constructed with a die-cast aluminum case, black anodized finish, and a polycarbonate front, the Model 2320 Magnehelic Gage is designed for durability and longevity. The units IP54 protection rating shields it from dust and limited moisture, making it well-suited for challenging industrial environments.

Precise and Versatile Pressure Measurements

The 2320 model offers a unique scale of -10 to 0 to +10 inch WC, supplying highly accurate readings with a 2% margin of full scale. Its diaphragm sensing mechanism ensures reliable monitoring of low differential pressures, suitable for air and non-corrosive gas applications across different sectors.

User-Friendly Installation and Maintenance

Equipped with a back process connection and external zero adjustment, this gage is simple to install and calibrate. Accessories like mounting brackets, screws, and a comprehensive instruction manual make both surface and flush mounting straightforward for varied operational needs.

FAQs of Dwyer USA Model 2320 Magnehelic Gage Range 10-0-10 Inch WC:

Q: How is the Dwyer Model 2320 Magnehelic Gage installed for best results?

A: The Model 2320 can be mounted on any flat surface using the supplied mounting brackets and screws. Installation is further simplified with its back process connection (1/8 NPT). Detailed guidelines are provided in the instruction manual for surface or flush mount setups.Q: What media can the Model 2320 Magnehelic Gage accurately measure?

A: This gage is specifically developed to measure low differential pressures of air and other non-corrosive, compatible gases. It is not suitable for liquids or aggressive chemical media.Q: When should I perform zero adjustment on the Magnehelic Gage?

A: Zero adjustment is recommended prior to initial use, after any significant temperature change, or following extended periods of inactivity. The built-in external adjustment knob allows for quick recalibration without opening the housing.Q: Where can the Model 2320 Magnehelic Gage be used most effectively?

A: The gage is ideal for environments like HVAC systems, clean rooms, filter monitoring stations, and ventilation ducts where monitoring low differential air or gas pressures is critical.Q: What benefits does the analog display and adjustable pointer provide?

A: The analog display with a red adjustable pointer allows for quick, accurate visual readings and makes it easy to set reference marks or alert thresholds, enhancing operational efficiency and safety.Q: How does the overpressure protection feature enhance the devices reliability?

A: The Model 2320 is designed to safely withstand overpressures up to 15 psi, significantly reducing risk of damage from unexpected surges and ensuring reliable performance across its service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer USA Model 2020 Magnehelic Gage Range 0-20 Inch WC

Minimum Order Quantity : 12 Pieces

Display : Analog

Mount Type : Other, Surface or flush mounting

Finishing : Other, Black anodized aluminum casing with clear acrylic cover

Measure Pressure Of : Other, Air and noncorrosive gases

Seal Material : Silicone rubber

Dwyer USA Model 2150 Magnehelic Gage Range 0-150 Inch WC

Minimum Order Quantity : 12 Pieces

Display : Analog

Mount Type : Other, Surface or flush mounting

Finishing : Other, Powdercoated diecast aluminum case

Measure Pressure Of : Other, Low air and noncorrosive gas differential pressure

Seal Material : Silicone diaphragm

Dwyer 2002- AV Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Display : Analog

Mount Type : Other, Surface or Flush Mount

Finishing : Other, Matte/Satin finish

Measure Pressure Of : Other, Air and Compatible Gases

Seal Material : Silicone Rubber

Dwyer 2215 Magnehelic Differential Pressure Gauge 0-15 PSI

Minimum Order Quantity : 12 Pieces

Display : Analog

Mount Type : Other, Surface or Flush Mounting

Finishing : Other, Textured Diecast Aluminum Case

Measure Pressure Of : Other, Air and Noncombustible Gases

Seal Material : Silicone

Send Inquiry

Send Inquiry