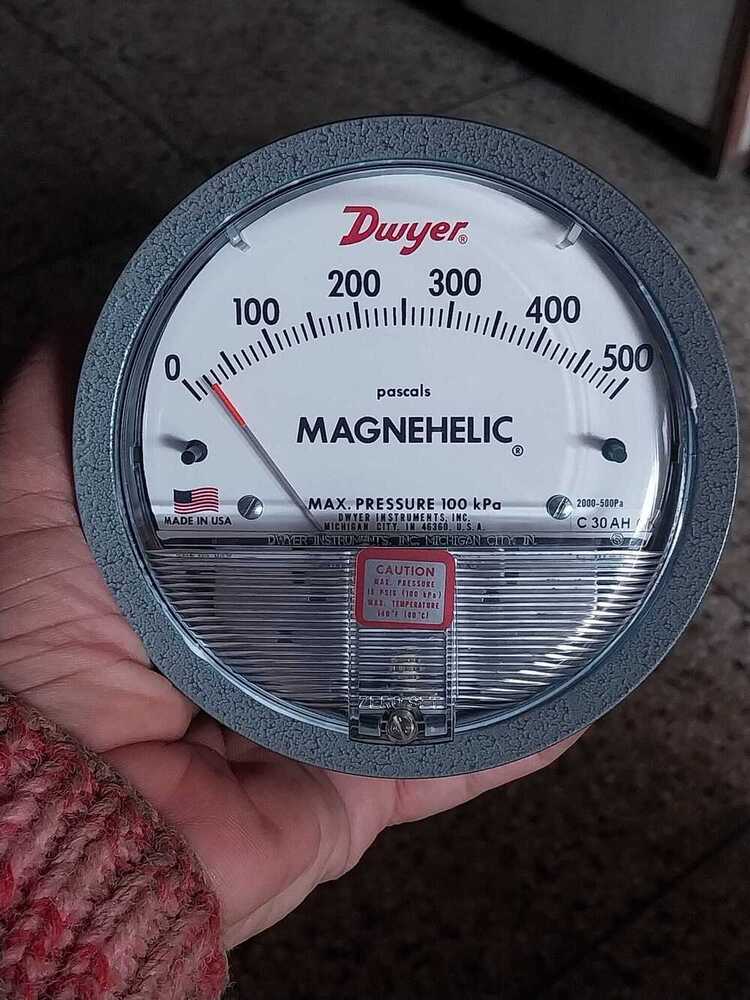

Dwyer USA Magnehelic Gauges 0 To 40 Inch WC

Dwyer USA Magnehelic Gauges 0 To 40 Inch WC Specification

- Grade

- Industrial

- Thread

- No Thread Connection

- Seal Material

- Silicone rubber

- Sensor Type

- Differential Pressure

- Outer Size

- Approx. 4 inch (100 mm) diameter

- Display

- Analog Dial

- Material

- Die-cast aluminium case, acrylic lens

- Dial Material

- White acrylic with printed scale

- Pointer Material

- Black anodized aluminum

- Processing Type

- Precision engineered

- Diameter

- 100 mm

- Glass Size

- 100 mm circular window

- Mount Type

- Surface or flush mount

- Scale Range

- 0 to 40 inch WC (Water Column)

- Accuracy

- 2% of full scale

- Finishing

- Powder coated aluminium case

- Measure Pressure Of

- Air and compatible gases

- Accessories

- Standard mounting bracket, two 1/8 NPT plugs

Dwyer USA Magnehelic Gauges 0 To 40 Inch WC Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Eastern Europe, Africa, Middle East, South America, Western Europe, Asia, Central America, North America

- Main Domestic Market

- All India

About Dwyer USA Magnehelic Gauges 0 To 40 Inch WC

Dwyer USA Magnehelic Gauges 0 To 40 Inch WC

| Model | Description |

| 2040 | Differential pressure gage, range 0-40" w.c., minor divisions 1.0. |

The industry standard in indicating low air or gas pressures of positive, negative, or differential pressures.

Large, easy-to-read 4" (102 mm) dial.

No manometer fluid to evaporate, freeze, or cause toxic or leveling problems.

INCLUDES

Two 1/8" NPT plugs, two 1/8" rubber tubing adapters, and three mounting adapters with screws

MORE ABOUT THIS ITEM

The Magnahelic guage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems, and pressures in fluid amplifier or fluidic systems. The gauge's motion is damped with high-viscosity silicone fluid. The zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness. Rugged design resists shock, vibration, and overpressure.

The helix is precision-made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the maganetic field to move the pointer across the scale. The samarium cobalt magnet is mounted at one end of the range spring and rotates the helix without mechanical linkages.

Specifications & Description

| Accuracy | ±3% full-scale |

| Dial Size (in) | 4 |

| Dial Size (mm) | 102 |

| Min Pressure (in WC) | 0 |

| Max Pressure (in WC) | 0.5 |

| Min Temperature (° F) | 20 |

| Max Temperature (° F) | 140 |

| Min Temperature (° C) | 7 |

| Max Temperature (° C) | 60 |

| Liquid Fill | Silicone |

| Case | Aluminum |

| Lens Material | Polycarbonate |

| Process Connection | 1/8" NPT(F) |

| Unit Of Measurement | " WC |

| Display | analog dial |

| Media Compatibility | Air and noncombustible, compatible gases |

| Description | Magnehelic Differential Pressure Gauge, 2040: 0-40" w.c |

Precision Differential Pressure Monitoring

The Dwyer Magnehelic Gauge 2000-40 offers accurate measurement of differential pressure, making it indispensable for industrial environments. The instruments 2% accuracy ensures consistent monitoring, while its durable construction and powder-coated aluminum housing provide resilience in tough conditions. Designed to be low maintenance, this gauge features an external adjustment screw for zero point calibration, ensuring optimum performance throughout its lifetime.

Ideal for Industrial Air Applications

Engineered for versatility, this Magnehelic Gauge can be surface or flush mounted in various industrial settings, including filtering systems, fan and blower monitoring, and clean room pressure measurement. Its 100 mm analog dial is easy to read and housed behind an acrylic lens, making it suitable for both daily operations and critical monitoring tasks where prompt detection of pressure variations is essential.

FAQs of Dwyer USA Magnehelic Gauges 0 To 40 Inch WC:

Q: How is the Dwyer 2000-40 Magnehelic Gauge installed and what ports does it use?

A: The Dwyer 2000-40 Magnehelic Gauge can be mounted either on a surface or flushed into a panel using the provided standard mounting bracket. It utilizes two 1/8" NPT pressure portsone for high and one for low pressurewhich connect to your differential pressure source.Q: What are the typical applications for this differential pressure gauge?

A: This Magnehelic Gauge is designed for use in filter monitoring, fan and blower pressure measurement, clean room pressure, duct static pressure, and measuring pressure drop across orifice plates. It is suitable for use in industrial environments where monitoring air and compatible gases is critical.Q: When should the external zero adjustment screw be used?

A: The external zero adjustment screw should be used during installation or when recalibrating the gauge to ensure the pointer rests exactly at zero under no pressure. This helps maintain accurate readings throughout the gauges service life.Q: Where can the Dwyer Magnehelic Gauge be utilized?

A: This gauge is commonly installed in HVAC systems, clean rooms, industrial process setups, filter housings, and ductwork. Its robust, powder-coated aluminium case makes it appropriate for use in demanding industrial settings across India.Q: What is the process for reading the pressure measurement on this gauge?

A: Simply observe the analog dial, which displays differential pressure from 0 to 40 inches of water column (WC). The black anodized aluminum pointer indicates the current pressure value against the clearly printed scale on the white acrylic dial.Q: How does using the Dwyer Magnehelic Gauge benefit industrial operations?

A: This gauge helps ensure optimal performance by providing reliable, real-time pressure monitoring. It aids in detecting filter blockages, maintaining clean room standards, and verifying system integrity, contributing to efficient operations and reduced maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dwyer 2000 Magnehelic Differential Pressure Gage Category

DWYER Magnehelic Air Gauge - Manometer

Dial Material : Plastic

Pointer Material : Alloy

Thread : 1/8" female NPT duplicate high and low pressure taps one pair side and one pair back

Display : Analog

Scale Range : MM WC/ CM / PAC / KPA / INCH

Processing Type : Standard

Dwyer USA Magnehelic Gauges 0.5-0-0.5 Inch WC

Dial Material : Other, White Enamel

Pointer Material : Aluminum

Thread : 1/8 NPT Female Connections

Display : Analog Dial

Scale Range : 0.500.5 Inch WC

Processing Type : Other, Precision Calibrated

Dwyer USA Magnehelic Gauges 0 To 150 Inch WC

Dial Material : Other, Acrylic Plastic

Pointer Material : Other, Aluminium

Thread : 1/8 NPT

Display : Analog

Scale Range : 0 to 150 Inch WC

Processing Type : Other, Precision Machined

Dwyer USA Magnehelic Gauges 0 To 8.0 Inch WC

Dial Material : Other, Aluminum (With Printed Scale)

Pointer Material : Plastic

Thread : 1/8 NPT Female Side and Back Connections

Display : Analog

Scale Range : 0 to 8.0 Inches Water Column (WC)

Processing Type : Other, Machined Housing

Send Inquiry

Send Inquiry