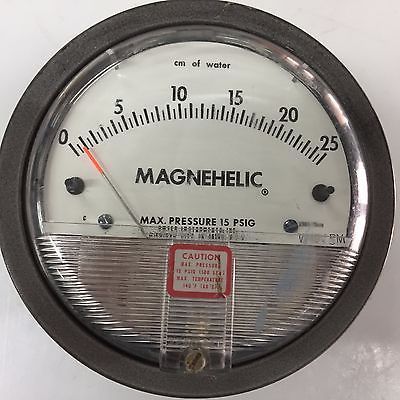

Dwyer Magnehelic Differential Pressure Gauge Model 2000-25KPA

Dwyer Magnehelic Differential Pressure Gauge Model 2000-25KPA Specification

- Sensor Type

- Diaphragm-operated mechanical sensor

- Seal Material

- Silicone rubber

- Bourdon Tube

- Not Applicable (Diaphragm type)

- Thread

- 1/8 NPT female

- Display

- Analog

- Grade

- Industrial

- Outer Size

- 115 mm diameter approx.

- Material

- Die-cast aluminum case, acrylic cover

- Dial Material

- White aluminum with printed markings

- Pointer Material

- Red acrylic

- Processing Type

- Mechanical

- Diameter

- 115 mm approx.

- Glass Size

- 102 mm (4)

- Mount Type

- Surface or panel mount

- Scale Range

- 0-25 kPa

- Accuracy

- 2% of full scale

- Finishing

- Die-cast aluminum case, gray finish

- Measure Pressure Of

- Air and compatible gases

- Accessories

- Two 1/8 NPT plugs, self-tapping mounting screws, and instruction sheet included

Dwyer Magnehelic Differential Pressure Gauge Model 2000-25KPA Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, South America, Middle East, Africa, Central America, Western Europe, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Dwyer Magnehelic Differential Pressure Gauge Model 2000-25KPA

Dwyer Magnehelic Differential Pressure Gauge Model 2000-25KPA

Dwyer 2000-25KPA MAGNEHELIC, DIFFERENTIAL PRESSURE GAUGE, 0/25KPA

- Precision litho-printed scale is accurate and easy to read.

- Red tipped pointer of heat treated aluminum tubing is easy to see. It is rigidly mounted on the helix shaft.

- Pointer stops of molded rubber prevent pointer over-travel without damage.

- "Wishbone" assembly provides mounting for helix, helix bearings and pointer shaft.

- Jeweled bearings are shock-resistant mounted; provide virtually friction-free motion for helix. Motion damped with high viscosity silicone fluid.

- Zero adjustment screw is conveniently located in the plastic cover, and is accessible without removing the cover. O-ring seal provides pressure tightness.

- Helix is precision made from an alloy of high magnetic permeability. Mounted in jeweled bearings, it turns freely, following the magnetic field to move the pointer across the scale.

- Samarium Cobalt magnet mounted at one end of range spring rotates helix without mechanical linkages.

- Calibrated range spring is flat spring steel. Small amplitude of motion assures consistency and long life. It reacts to pressure on diaphragm. Live length adjustable for calibration.

- Silicone rubber diaphragm with integrally molded O-ring is supported by front and rear plates. It is locked and sealed in position with a sealing plate and retaining ring. Diaphragm motion is restricted to prevent damage due to overpressures.

- Die cast aluminum case is precision made and iridite-dipped to withstand 168 hour salt spray corrosion test. Exterior finished in baked dark gray hammerloid. One case size is used for all standard pressure options, and for both surface and flush mounting.

- Blowout plug of silicone rubber protects against overpressure on 15 psig rated models. Opens at approximately 25 psig.

- O-ring seal for cover assures pressure integrity of case.

Reliable Differential Pressure Monitoring

The Dwyer Magnehelic Model 2000-25KPA allows for accurate monitoring of pressure differences in air and compatible gases. Primarily used in HVAC, clean rooms, and filtration systems, its diaphragm sensor delivers dependable performance and long-term stability for demanding industrial environments.

Easy Installation and Operation

Designed for straightforward integration, this gauge mounts vertically to panels or surfaces using the included hardware. With external front zero adjustment, calibration and ongoing maintenance are quick and convenient. Two clearly marked NPT connections ensure simple connection to your pressure sources.

Durable Construction and Safety Features

With a die-cast aluminum case and silicone gasket, the Model 2000-25KPA stands up to harsh operating environments. The built-in overpressure protection offers peace of mind, while the robust acrylic and aluminum components provide lasting durability and reliable operation for everyday industrial use.

FAQs of Dwyer Magnehelic Differential Pressure Gauge Model 2000-25KPA:

Q: How do I install the Dwyer Magnehelic Model 2000-25KPA differential pressure gauge?

A: The gauge can be installed vertically on a surface or panel using the provided self-tapping mounting screws. Simply connect the two 1/8" NPT female high and low pressure taps to your system. The instruction sheet outlines recommended installation steps for best accuracy and safety.Q: What types of applications is this differential pressure gauge suitable for?

A: This gauge is ideal for monitoring air and compatible gas pressures in HVAC systems, filters, blower monitoring, draft measurement, and clean room environments. Its mechanical, diaphragm-based sensor ensures reliable readings in various industrial scenarios.Q: When should I adjust the zero point of the gauge, and how is it done?

A: Zero adjustment is needed when calibrating the gauge or if readings drift over time. The Model 2000-25KPA features an external front adjustment screw, allowing users to set the dial to zero without removing the unit from its mount. Adjust only when both pressure ports are open to atmosphere.Q: Where should the Dwyer Magnehelic gauge be mounted for best results?

A: For optimal accuracy, the gauge should be mounted vertically using the supplied hardware. This orientation aligns with the gauges design and ensures the diaphragm sensor operates within its specified accuracy range.Q: What is the benefit of the overpressure safety feature on this model?

A: The hazardous overpressure protection and relief plug help prevent damage in case of accidental pressure spikes up to the 172 kPa (25 psi) maximum. This ensures user safety and prolongs the lifespan of the gauge in demanding settings.Q: How does the mechanical diaphragm sensor work in this device?

A: The gauge uses a diaphragm-operated mechanical sensor that detects the difference between high and low pressure inputs. This movement is translated to the red pointer on a clear analog scale, providing immediate and accurate differential pressure readings.Q: What accessories come with the Dwyer Magnehelic Model 2000-25KPA?

A: Each gauge package includes two 1/8" NPT plugs, self-tapping mounting screws, and a detailed instruction sheet, making setup and configuration straightforward.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer Magnehelic Differential Pressure Gauge Model 2000-0.5KPA

Minimum Order Quantity : 12 Pieces

Finishing : Other, Powder coated diecast aluminum housing

Glass Size : Clear polycarbonate cover, approx. 4 inches

Accessories : Two 1/8 NPT plugs, two mounting screws, instruction sheet

Outer Size : Approx. 4 inches diameter (100 mm)

Scale Range : 0 to 0.5 kPa

Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC

Minimum Order Quantity : 12 Pieces

Finishing : Other, Black powder coated aluminum casing

Glass Size : 4 inch (101.6 mm) viewing window

Accessories : Two 1/8 NPT plugs, selftapping screws, plastic tubing, instruction sheet

Outer Size : Standard approx. 4 inch (101.6 mm) dia.

Scale Range : 505 Inch WC

Dwyer USA 2003 Magnehelic Gage Range 0-3.0 Inch WC

Minimum Order Quantity : 12 Pieces

Finishing : Other, Diecast aluminum case, gray acrylic finish

Glass Size : 4 inch dial window

Accessories : Two 1/8 NPT plugs, pipe mounting bracket, and screw pack (standard kit)

Outer Size : 4 inch diameter (approx.)

Scale Range : 03.0 Inch WC (Water Column)

Dwyer 2215 Magnehelic Differential Pressure Gauge 0-15 PSI

Minimum Order Quantity : 12 Pieces

Finishing : Other, Textured Diecast Aluminum Case

Glass Size : Full view, clear acrylic

Accessories : Two 1/8 NPT plugs, two mounting screws, and instruction sheet

Outer Size : 4 inches (nominal)

Scale Range : 015 PSI

Send Inquiry

Send Inquiry