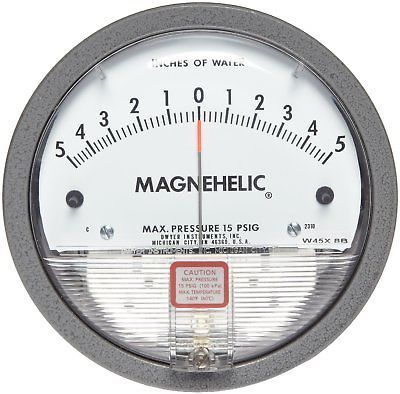

Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC

Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC Specification

- Display

- Analog dial

- Thread

- 1/8 NPT

- Grade

- Industrial

- Bourdon Tube

- Not applicable (Diaphragm type)

- Seal Material

- Rubber (neoprene)

- Outer Size

- Standard approx. 4 inch (101.6 mm) dia.

- Sensor Type

- Diaphragm differential

- Material

- Die-cast aluminum case, acrylic cover

- Dial Material

- White aluminum with printed scale

- Pointer Material

- Red-tipped high-visibility plastic

- Processing Type

- Precision mechanical movement

- Diameter

- Approx. 4 inch (101.6 mm)

- Glass Size

- 4 inch (101.6 mm) viewing window

- Mount Type

- Surface/Panel or flush mount

- Scale Range

- 5-0-5 Inch WC

- Accuracy

- 2% of full scale

- Finishing

- Black powder coated aluminum casing

- Measure Pressure Of

- Differential (air and non-corrosive gases)

- Accessories

- Two 1/8 NPT plugs, self-tapping screws, plastic tubing, instruction sheet

Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Australia, Central America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, North America

- Main Domestic Market

- All India

About Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC

Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC

Bezel Provides Flange For Flush Mounting in Panel. Clear Plastic Face is Highly Resistant to Breakage.Provides Undistorted Viewing of Pointer and Scale.

Dwyer 2310 Differential Pressure Gage, Range5-0-5 Inch WC(inches of water), minor divisions.020, calibrated for vertical scale position

Using Dwyer's simple, frictionless Magnehelic gage movement, it quickly indicates low air or non-corrosive gas pressures--either positive, negative (vacuum) or differential. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. It's inexpensive, too.

The Magnehelic gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

What's included with the Dwyer 2310

Dwyer 2310 Magnehelic Differential Pressure Gauge (5-0-5Inchw.c.), Vertical Scale

Accurate Differential Pressure Measurement

Designed for high-precision performance, the Dwyer Model 2310 Magnehelic Gauge supports applications where monitoring low airflow or pressure differentials is essential. Its 2% full-scale accuracy and reliable diaphragm-sensor system ensure dependable readings for critical industrial environments.

Durable Construction and Flexible Mounting

With a robust die-cast aluminum body and black powder-coated finish, the gauge stands up well in tough conditions. The surface or panel/flush mounting options provide installation versatility, while the 4-inch viewing window guarantees clear visibility of readings.

Comprehensive Accessories for Easy Installation

Each Magnehelic Gauge comes complete with two 1/8 NPT plugs, self-tapping screws, plastic tubing, and an instruction sheet. This complete accessory package enables quick, straightforward installation and immediate use in your setup.

FAQs of Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC:

Q: How is the Dwyer 2310 Magnehelic Gage typically installed?

A: This gauge is designed for surface, panel, or flush mounting, with a preference for vertical orientation to maintain calibrated accuracy. Accessories such as mounting screws and tubing are supplied to facilitate straightforward installation.Q: What process does the gauge use to measure differential pressure?

A: The Model 2310 utilizes a diaphragm-type sensor that responds to differences in pressure between the high and low side ports, displaying the measurement on an analog dial for immediate and precise readings.Q: When should the zero adjustment be performed and how do I do it?

A: Zero adjustment should be checked during installation or after relocation to ensure accuracy. The adjustment is made externally using the adjustment screw provided, as detailed in the instruction sheet.Q: Where can this gage be used effectively?

A: It is best suited for industrial applications involving air or non-corrosive gases, such as HVAC systems, clean rooms, and filter monitoring, especially across manufacturing facilities and laboratories in India.Q: What are the benefits of using the Dwyer 2310 Magnehelic Gage?

A: Users benefit from rapid response time (less than 1 second), precise measurement, durable construction, and ease of installation, making it ideal for maintaining optimal pressure differentials in critical processes.Q: How does the enclosure rating affect the gages performance?

A: The IP54 enclosure rating protects the instrument from dust and water splashes, enhancing its durability and reliability in challenging industrial environments.Q: What accessories are included with the gage upon purchase?

A: The gauge comes with two 1/8 NPT plugs, self-tapping screws, plastic tubing, and an instruction manual to support hassle-free installation and operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer USA Model 2120 Magnehelic Gage Range 0-120 Inch WC

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of Full Scale

Display : Analog

Thread : 1/8 NPT female connection

Scale Range : 0120 inch WC

Dwyer USA Model 2300-0 Magnehelic Gage Range 0.25-0-0.25 Inch WC

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of Full Scale

Display : Analog

Thread : 1/8 NPT Female

Scale Range : 0.2500.25 Inch WC (Water Column)

Dwyer 2000-0 Magnehelic Gage Range 0-.50 Inch WC

Price 4800 INR

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of Full Scale

Display : Analog

Thread : 1/8 NPT

Scale Range : 00.50 Inch WC

Dwyer 2050D Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of full scale

Display : Analog

Thread : 1/8 NPT female connection

Scale Range : 050 Pa (00.2 inch w.c.)

Send Inquiry

Send Inquiry