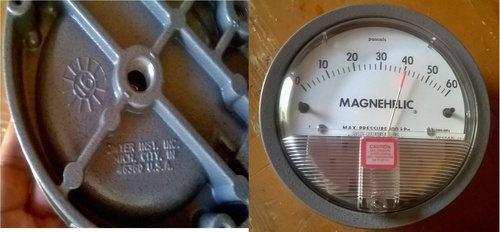

Dwyer 2000-60PA Magnehelic Differential Pressure Gauge

Dwyer 2000-60PA Magnehelic Differential Pressure Gauge Specification

- Seal Material

- Silicone Rubber

- Outer Size

- 115 mm diameter approx.

- Display

- Analog

- Grade

- Industrial

- Sensor Type

- Diaphragm

- Thread

- 1/8 NPT

- Material

- Die Cast Aluminum Case

- Dial Material

- Aluminum with Powder-Coated Finish

- Pointer Material

- Aluminum

- Processing Type

- Calibrated Mechanical

- Diameter

- 4 inches (approx. 100 mm)

- Glass Size

- Full view, approx. 100 mm

- Mount Type

- Surface or Flush

- Scale Range

- 0-60 Pa

- Accuracy

- 2% of FS

- Finishing

- Textured Black Enamel Case

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Two 1/8 NPT plugs, two 1/8 NPT pipe thread to rubber tubing adapter, and three mounting adapters with screws

Dwyer 2000-60PA Magnehelic Differential Pressure Gauge Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, South America, Middle East, Africa, Western Europe, Asia, Central America, Eastern Europe, North America

- Main Domestic Market

- All India

About Dwyer 2000-60PA Magnehelic Differential Pressure Gauge

Dwyer Instruments 2000-60PA

Diff.Pressure Gage,0-60Pa,Minor Divisions 2.0,Cal/Vert.Scale

Precision Engineering for Demanding Applications

Designed specifically for the accurate measurement of minimal pressure differentials, the Dwyer 2000-60PA integrates a high-grade diaphragm sensor for robust performance. With a calibration process ensuring consistent delivery, it enables users to confidently monitor and control airflows or filter conditions in industrial environments.

Flexible and Durable Construction

This gauge features a durable die-cast aluminum body with a textured black enamel finish, making it suitable for harsh conditions. Its full-view glass face offers clear visibility, while the silicone rubber seals and powder-coated dial enhance longevity and resistant operation. Various mounting options cater to diverse installation requirements.

FAQs of Dwyer 2000-60PA Magnehelic Differential Pressure Gauge:

Q: How do I install the Dwyer 2000-60PA Magnehelic Differential Pressure Gauge?

A: The gauge may be flush or surface mounted using the supplied mounting adapters and screws. Ensure a vertical orientation for proper operation, and connect the included 1/8 NPT plugs or pipe thread to rubber tubing adapters as required. Refer to the user manual for detailed step-by-step instructions.Q: What types of media can be safely measured with this pressure gauge?

A: The Dwyer 2000-60PA is intended for use with air and non-corrosive gases only. Exposure to corrosive substances can damage the diaphragm sensor and internal components.Q: When is zero adjustment necessary, and how is it performed?

A: Zero adjustment should be performed prior to taking critical measurements or when relocating the gauge. This is easily done using the external screw adjustment, which can be accessed without dismantling the enclosure.Q: Where can this differential pressure gauge be used most effectively?

A: Typical applications include monitoring filter status, airflow, or pressure in HVAC systems, clean rooms, laboratories, and industrial process control, provided the operating temperature remains within -7C to +60C.Q: What is the benefit of the IP52 enclosure rating for this gauge?

A: With an IP52 rating, the Magnehelic gauge is protected against dust ingress and limited dripping water, enhancing its reliability and lifespan in typical industrial and commercial indoor environments.Q: How accurate and precise are the measurements provided by this gauge?

A: It delivers a resolution of 0.5 Pa and an accuracy of 2% of full scale, making it highly reliable for both qualitative and quantitative low-pressure readings.Q: What accessories are provided with the Dwyer 2000-60PA, and how do they facilitate usage?

A: Included are two 1/8 NPT plugs, two pipe thread to rubber tubing adapters, and three mounting adapters with screws, which all help enable versatile installation and easy connectivity to different ductwork or tubing configurations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer 2204 Magnehelic Differential Pressure Gauge 0-4 PSI

Minimum Order Quantity : 12 Pieces

Accessories : Mounting Bracket (Included), Two 1/8 NPT Plugs, Three Mounting Adapters

Thread : 1/8 NPT

Dial Material : Other, HighContrast White Aluminum

Scale Range : 04 PSI

Pointer Material : Other, Precision Balanced Aluminum

Dwyer 2005D Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Accessories : 2 Pressure Taps, Mounting Screws, Instruction Sheet

Thread : 1/8 NPT Female

Dial Material : Other, Acrylic

Scale Range : 00.5 inches w.c. (Water Column)

Pointer Material : Other, Precision Balanced Aluminum

Dwyer Magnehelic Differential Pressure Gauge Model 2000-20KPA

Minimum Order Quantity : 12 Pieces

Accessories : Two mounting brackets, screws, and instruction sheet

Thread : 1/8 NPT Female

Dial Material : Other, White aluminum with black/red markings

Scale Range : 020 kPa

Pointer Material : Other, Black aluminum pointer

Dwyer USA Model 2100 Magnehelic Gage Range 0-100 Inch WC

Minimum Order Quantity : 12 Pieces

Accessories : Two 1/8 NPT plugs, four flush mounting adapters, and two 1/8 rubber tubing adapters

Thread : No threaded connection (uses rear or surface mounting)

Dial Material : Other, White aluminum dial with printed scale

Scale Range : 0100 Inch W.C. (Water Column)

Pointer Material : Other, Red tipped aluminum pointer

Send Inquiry

Send Inquiry