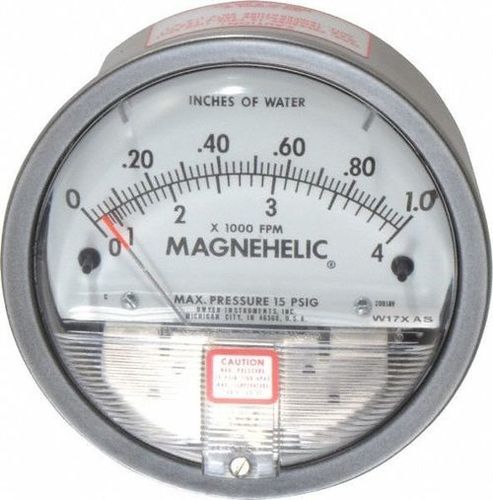

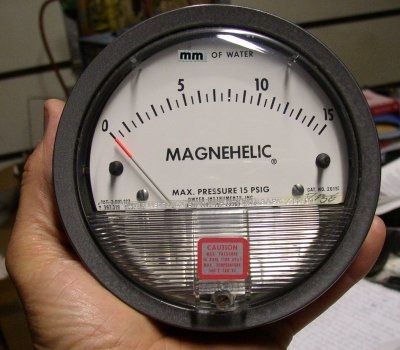

Dwyer 2000-300PA Magnehelic Differential Pressure Gauge

Dwyer 2000-300PA Magnehelic Differential Pressure Gauge Specification

- Thread

- 1/8 NPT Female Connection

- Sensor Type

- Differential Pressure Sensor

- Display

- Analog

- Outer Size

- About 120 mm Diameter

- Grade

- Industrial Grade

- Seal Material

- Silicone Rubber

- Material

- Die Cast Aluminum Case with Acrylic Cover

- Dial Material

- Acrylic

- Pointer Material

- Aluminum

- Processing Type

- Mechanical

- Diameter

- 4 inch (101.6 mm) dial

- Glass Size

- Full Face, Clear Acrylic

- Mount Type

- Surface or Flush Mount

- Scale Range

- 0-300 Pa

- Accuracy

- 2% of Full Scale

- Finishing

- Corrosion Resistant Enclosure

- Measure Pressure Of

- Air and Non-Corrosive Gases

- Accessories

- Mounting Hardware, Two 1/8 NPT Plugs, Two 1/8 NPT to Rubber Tubing Adapters, Mounting Panel

Dwyer 2000-300PA Magnehelic Differential Pressure Gauge Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- South America, Middle East, Western Europe, Central America, Africa, Asia, Eastern Europe, North America, Australia

About Dwyer 2000-300PA Magnehelic Differential Pressure Gauge

Dwyer 2000-300PA Magnehelic Differential Pressure Gauge

Series 2000 Magnehelic Differential Pressure Gage, 0-300 Pa,

Minor Divisions 10.0

Indicate Positive, Negative or Differential

Select the Magnehelic gage for high accuracy-guaranteed. Using Dwyers simple, frictionless Magnehelic gage movement, it quickly indicates low air or non-corrosive gas pressures. The design resists shock, vibration and over-pressures. No manometer fluid to evaporate, freeze or cause toxic or leveling problems. Its inexpensive, too.

The Magnehelic gage is the industry standard to measure fan and blower pressures, filter resistance, air velocity, furnace draft, pressure drop across orifice plates, liquid levels with bubbler systems and pressures in fluid amplifier or fluidic systems. It also checks gas-air ratio controls and automatic valves, and monitors blood and respiratory pressures in medical care equipment.

Product Applications

Approvals

Features

Reliable Measurement for Critical Environments

The Dwyer 2000-300PA Magnehelic Gauge offers robust and precise differential pressure monitoring for applications such as clean rooms, HVAC systems, and filter status verification. Its industrial-grade design with advanced sealing and a corrosion-resistant enclosure ensures long-lasting performance, even in demanding settings. The analog display provides clear, immediate readings, making it suitable for environments where reliability and accuracy are essential.

Flexible Installation and User-Friendly Design

Designed with both side and rear port connections, the 2000-300PA makes installation straightforward across a range of system configurations. Surface or flush mounting options further support integration into panels or direct surfaces. The included mounting hardware, adapters, and plugs simplify setup, while the external adjustment screw allows for hassle-free zero calibration to maintain accurate readings over time.

FAQs of Dwyer 2000-300PA Magnehelic Differential Pressure Gauge:

Q: How do I install the Dwyer 2000-300PA Magnehelic Differential Pressure Gauge?

A: This gauge offers flexible installation through surface or flush mounting, thanks to its included mounting panel and hardware. Side and rear 1/8 NPT female ports allow adaptation to different piping layouts. Two NPT plugs and two NPT-to-rubber tubing adapters are provided for easy connection to your application.Q: What is the primary usage of the 2000-300PA Magnehelic Gauge?

A: The 2000-300PA is widely used for monitoring differential pressures in clean rooms, HVAC systems, filter performance checks, and for indicating air velocity. Its accuracy and robustness make it suitable for industrial-grade applications measuring air or non-corrosive gases.Q: Where can this gauge be effectively deployed?

A: It can be installed wherever precise low-pressure differential monitoring is needed, such as clean rooms, laboratories, HVAC ducts, and filtration systems. Its corrosion-resistant finish and IP52 enclosure rating ensure it withstands challenging industrial environments.Q: What benefits does the external adjustment screw offer?

A: The external zero adjustment screw allows users to recalibrate the gauge on-site without disassembly. This feature ensures ongoing measurement accuracy and saves maintenance time, particularly in environments prone to temperature or pressure fluctuations.Q: When should the gauge be recalibrated?

A: Recalibration is advisable whenever there is noticeable drift in readings, after maintenance, or upon installation in a new environment. Regular calibration intervals may also be scheduled based on your quality guidelines or regulatory requirements.Q: How does the analog display and mechanical design benefit users?

A: The full-face, clear acrylic dial provides quick, precise analog readings, which are crucial for immediate visual inspection. The mechanical design ensures stable operation without the need for power, enhancing reliability during power interruptions.Q: What pressure and temperature ranges does this model support?

A: The Dwyer 2000-300PA measures up to 300 Pa differential pressure, tolerates a max static pressure of 103 kPa, and can withstand overpressures up to 172 kPa before rupture. It operates effectively between -7C and 60C, covering typical ambient environments in industrial and laboratory settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sensocon - Dwyer S2000 Differential Pressure Gauge Category

Dwyer USA Model 2310 Magnehelic Gage Range 5-0-5 Inch WC

Minimum Order Quantity : 12 Pieces

Display : Analog dial

Outer Size : Standard approx. 4 inch (101.6 mm) dia.

Grade : Industrial

Material : Other, Diecast aluminum case, acrylic cover

Accuracy : 2% of full scale

Dwyer USA Model 2020 Magnehelic Gage Range 0-20 Inch WC

Minimum Order Quantity : 12 Pieces

Display : Analog

Outer Size : 4 inch diameter

Grade : Industrial

Material : Other, Diecast aluminum case, acrylic cover

Accuracy : 2% of full scale

Dwyer 2001-AV Magnehelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Display : Analog

Outer Size : 4inch (standard housing)

Grade : Industrial

Material : Other, Diecast aluminum case, acrylic cover

Accuracy : 2% of full scale

Dwyer USA Magnehelic Gauges 5-0-5 MM WC

Display : Analog

Outer Size : Standard

Grade : Industrial Grade

Material : Other, Die Cast Aluminum Case, Acrylic Cover

Accuracy : 2% of Full Scale

Send Inquiry

Send Inquiry