Wire Mesh Filter

Wire Mesh Filter Specification

- Filter Type

- Mesh Filter

- Temperature Range

- -50C to 300C

- Media Type

- Gas, Liquid

- Flow Rate

- 10-30 L/min (depends on mesh size)

- Connecting Type

- Press Fit or Threaded

- Capacity

- Variable, depends on application

- Pressure

- Up to 10 Bar

- Efficiency (%)

- Up to 99%

- Cleaning Method

- Washable, Reusable

- Filtration Grade

- Medium

- Condition

- New

- Material

- Stainless Steel

- Mesh

- Fine Mesh (typically 60-200 mesh, customizable)

- Diameter

- Customizable or 50 mm (as standard sample)

- Construction

- Woven Wire Mesh

- Medium Filter

- Air, Oil, Liquid

- Weight

- 50-150 grams (depends on size)

- Shape

- Round or Cylindrical

- Feature

- High strength, corrosion resistance, reusable, easy to install

- Surface Treatment

- Polished or Plain

- Color

- Natural Silver

- Layer

- Single or Multi-layer

- Usage Life

- Long Service Life

- Micron Size

- 20 to 150 micron (customizable)

- Application

- Filtration in chemical, oil, pharmaceutical, water treatment, and food industries

- End Connection

- Open or Closed

- Packing Type

- Box or Carton

About Wire Mesh Filter

We are one of the reliable companies in the existing global market, engaged in manufacturing, exporting and supplying an excellent quality range of Wire Mesh Filter. This filter is widely used for air filtration purpose by removing solid particulates such as dust and bacteria from air in an efficient manner. The provided filter is manufactured at our hi-tech production unit using top-notch stainless steel wires with the aid of advanced techniques. Besides this, the offered Wire Mesh Filter can be availed from us at rock bottom prices.

Features:

- Sturdy construction

- Low maintenance

- Resistant to corrosion

- Easy to clean

Technical specification

| Minimum Order Quantity | 1 Number |

| Aluminum Mesh | SS Mesh |

| GI Mesh | 40 MICRON |

Premium Filtration for Demanding Applications

Designed for use in chemical, oil, pharmaceutical, water treatment, and food processing industries, the Wire Mesh Filter achieves up to 99% filtration efficiency while withstanding pressures up to 10 Bar and temperatures from -50C to 300C. Its robust woven stainless steel construction ensures longevity and reliability in harsh environments.

Adaptable & Customizable Filtration Solutions

Available in multiple mesh sizes, micron ratings, and end connection types (open or closed), our filters can be tailored to specific application requirements. The choice of polished or plain surfaces, single or multi-layer construction, and press fit or threaded connecting options allows versatility for diverse industrial systems.

FAQs of Wire Mesh Filter:

Q: How is the Wire Mesh Filter cleaned and maintained?

A: The filter is fully washable and designed for reuse. Regular cleaning with suitable solvents or water, depending on the filtered medium, helps maintain optimal performance. Its stainless steel construction ensures corrosion resistance during washing.Q: What customization options are available for this mesh filter?

A: Customers can specify micron size (from 20 to 150 micron), mesh count (typically 60-200 mesh), diameter (customizable or 50 mm standard), number of layers (single or multi-layer), shape (round or cylindrical), and end connections (open or closed). Surface finishes can be polished or plain.Q: Where can these wire mesh filters be used?

A: They are suitable for filtration tasks in chemical processing, oil refineries, pharmaceuticals, water purification systems, and food and beverage processinganywhere medium-grade filtration of air, oil, or liquids is required.Q: What is the benefit of a reusable filter design?

A: Reusable filters reduce operational costs and environmental impact, as they can be cleaned and reinstalled multiple times, eliminating the need for frequent replacements.Q: How is the mesh filter installed in a system?

A: Installation is straightforward, with options for press fit or threaded connections. The filter can easily be integrated into existing pipelines or filter housings without requiring specialized tools.Q: What factors affect the flow rate and filtration efficiency of the mesh filter?

A: Flow rate (10-30 L/min) and efficiency (up to 99%) depend on selected mesh size, micron rating, and filter diameter. Finer meshes yield higher filtration efficiency, while larger mesh openings provide higher flow rates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Manufacturers In India Delhi Category

HVAC Filter

Shape : Varied (rectangular cylindrical etc.)

Condition : New

Filter Type : HVAC Filter

Feature : Durable and reliable

Construction : Customizable, Other

Capacity : To be confirmed

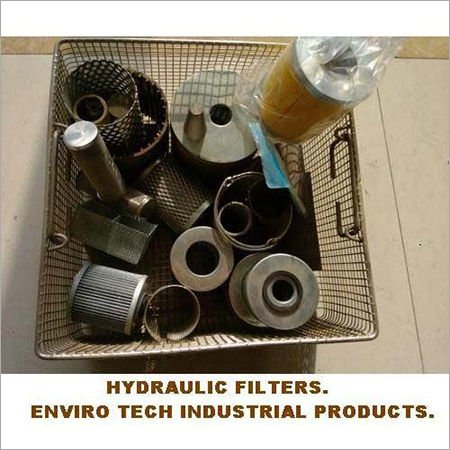

Hydraulic Filters

Shape : Cylinder

Condition : New

Filter Type : Return Line / Suction / Pressure line

Feature : Removes particulate contaminants from hydraulic oil, Easy installation, Enhanced durability

Construction : Other, Cylindrical, Welded Seam

Capacity : Standard / Custom sizes available

Round Cartridge Filter

Shape : Round

Condition : New

Filter Type : Cartridge Filter

Feature : High dust holding capacity, easy installation, durable construction

Construction : Other, Round cartridge, pleated filter design

Capacity : Depends on filter size, up to 1200 m/h

Telecom Racks Foam Air Filter

Shape : Rectangular

Condition : New

Filter Type : Air Filter

Feature : High dust holding capacity, reusable, washable

Construction : Other, Rugged frame with foam media

Capacity : High

Send Inquiry

Send Inquiry