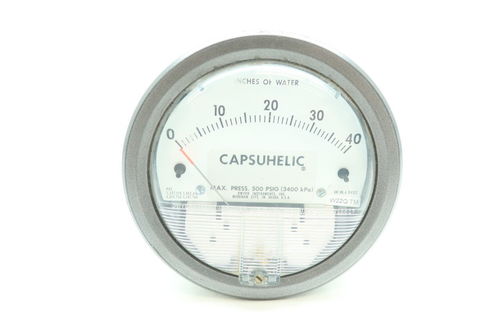

Dwyer 4020 Capsuhelic Differential Pressure Gauge

Dwyer 4020 Capsuhelic Differential Pressure Gauge Specification

- Outer Size

- Approximately 4 (101.6 mm) Diameter Case

- Seal Material

- Silicone Rubber

- Display

- Analog Gauge

- Thread

- 1/8 NPT Female

- Sensor Type

- Differential Pressure Sensor (Capsule Type)

- Bourdon Tube

- Not Applicable (Uses Capsule Element)

- Grade

- Industrial

- Material

- Die-cast Aluminum Body

- Dial Material

- Plastic (White Engraved)

- Pointer Material

- Metal

- Processing Type

- Precision Mechanical

- Diameter

- 4 inches (101.6 mm)

- Glass Size

- Approximately 4 inches (matches case diameter)

- Mount Type

- Panel Mount

- Scale Range

- 0-10 in H2O

- Accuracy

- 2% of Full Scale

- Finishing

- Powder Coated Aluminum Case

- Measure Pressure Of

- Air and Compatible Gases

- Accessories

- Mounting Bracket and Hardware

- Max Working Pressure

- 100 psi (6.89 bar)

- Overpressure Limit

- 120 psi (8.27 bar)

- Window Material

- Acrylic

- Enclosure Rating

- General Purpose

- Weight

- About 510 g (1.12 lbs)

- Operating Temperature Range

- -20 to 140°F (-6.67 to 60°C)

- Zero Adjustment

- External Adjustment Screw

- Connection Location

- Side Connections

Dwyer 4020 Capsuhelic Differential Pressure Gauge Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Paypal, Cash in Advance (CID), Cheque, Cash Advance (CA)

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Western Europe, Central America, Africa, Asia, North America

- Main Domestic Market

- All India

About Dwyer 4020 Capsuhelic Differential Pressure Gauge

Dwyer 4020 Capsuhelic Differential Pressure Gauge

Dwyer Instruments 402

Capsuhelic Differential Press. Gauge, 0-20 in H2O, brass case

Differential pressure gage, range 0-20" w.c.

The Capsuhelic gauge is designed to give fast, accurate indication of differential pressures. The gauge may be used as a readout device when measuring flowing fluids, pressure drop across filters, liquid levels in storage tanks and many other applications involving pressure, vacuum or differential pressure. Using the basic design of Dwyer's time-proven Magnehelic gauge, the Capsuhelic gauge contains a simple, frictionless movement that permits full scale readings as low as 0.5 in H2O. The pressure being measured is held within a capsule which is an integral part of the gauge. This containment of the pressure permits the use of the gauge on system pressures of up to 500 psig, even when differentials to be read are less than 0.1 in H2O. The diaphragm-actuated Capsuhelic gauge requires no filling liquid which might limit its outdoor applications. Zero and range adjustments are made from outside the gauge, and there is no need to disassemble the gauge in normal service. Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

Product Highlights

Brass case

0-20 in H2O

Robust Industrial Build

Built from precision die-cast aluminum and protected with a powder-coated finish, the Dwyer 4020 Capsuhelic Gauge is engineered for durability in harsh environments. Its general-purpose enclosure and silicone rubber sealing offer resilience and longevity, ensuring the gauge withstands demanding workplace conditions and provides extended service life.

User-Friendly Operation and Setup

Featuring side connections with 1/8 NPT female threads and an external zero adjustment screw, this gauge allows for straightforward setup, calibration, and maintenance. The supplied mounting bracket and hardware make the installation process efficient, while the analog display provides immediate visual feedback for differential pressure readings.

FAQs of Dwyer 4020 Capsuhelic Differential Pressure Gauge:

Q: How is the Dwyer 4020 Capsuhelic Differential Pressure Gauge installed?

A: The Dwyer 4020 gauge is designed for panel mounting. It comes with a mounting bracket and hardware, and connects via side-entry 1/8 NPT female threads. Ensure the panel cutout and mounting location accommodate its 4-inch diameter to secure a proper fit.Q: What types of media can this differential pressure gauge measure?

A: The gauge is suitable for measuring air and other compatible gases. It is not recommended for liquid measurements, as it is specifically calibrated for gaseous media to ensure accuracy and safety.Q: When should the zero adjustment be used?

A: Zero adjustment should be performed before the gauge is put into service or whenever readings appear offset. The external adjustment screw enables on-site calibration, ensuring accurate differential pressure measurement without disassembly.Q: Where should the Dwyer 4020 gauge be employed?

A: This gauge is ideal for monitoring airflow, filter status, or ventilation pressures in industrial, commercial, or laboratory environments across India. Its robust build and range make it suitable for many HVAC or cleanroom applications.Q: What process does the gauge use to measure differential pressure?

A: The instrument employs a mechanical capsule-type sensor to detect pressure differences between two points. Changes in pressure cause precise mechanical movement, which is translated to analog readings on the dial.Q: How does using this gauge benefit industrial operations?

A: It delivers highly accurate, real-time differential pressure data (2% of full scale), which is essential for optimizing filtration, airflow systems, or other pressure-dependent processes. Reliable readings contribute to improved system efficiency and reduced maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series 4000 Capsuhelic Differential Pressure Gage Category

Dwyer 4060 Capsuhelic Differential Pressure Gauge

Price 9871034100 INR

Minimum Order Quantity : 12 Pieces

Display : Analog

Thread : 1/8 NPT Female

Accuracy : 2% of Full Scale

Seal Material : BunaN

Dwyer 4006 Capsuhelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Display : Analog

Thread : 1/8 NPT Female

Accuracy : 2% of Full Scale

Seal Material : Neoprene

Dwyer 4001 Capsuhelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Display : Analog

Thread : 1/8 NPT Female

Accuracy : 2% of Full Scale

Seal Material : BunaN

Dwyer 4040 Capsuhelic Differential Pressure Gauge

Price 9871034100 INR

Minimum Order Quantity : 12 Pieces

Display : Analog

Thread : 1/8 NPT

Accuracy : 2% of full scale

Seal Material : Silicone rubber

Send Inquiry

Send Inquiry