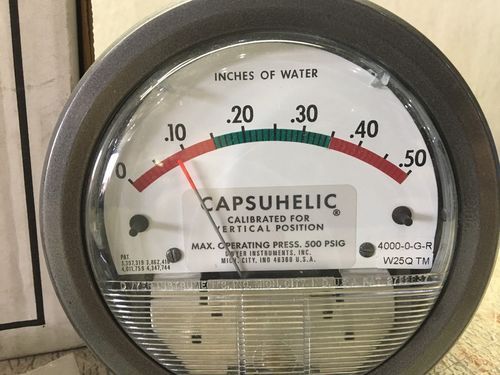

Dwyer 4001 Capsuhelic Differential Pressure Gauge

Dwyer 4001 Capsuhelic Differential Pressure Gauge Specification

- Outer Size

- Approximately 4 Diameter Case

- Display

- Analog

- Grade

- Industrial

- Thread

- 1/8 NPT Female

- Seal Material

- Buna-N

- Bourdon Tube

- No

- Sensor Type

- Differential Pressure Gauge

- Material

- Die-Cast Aluminum Case, Acrylic Lens, Buna-N Diaphragm

- Dial Material

- Acrylic

- Pointer Material

- Aluminum

- Processing Type

- Precision Machined

- Diameter

- 4 Inches (Approx. 101 mm)

- Glass Size

- Full View Front Lens

- Mount Type

- Surface Mount / Panel Mount

- Scale Range

- 0-1 InWC (Inches of Water Column)

- Accuracy

- 2% of Full Scale

- Finishing

- Powder Coated

- Measure Pressure Of

- Air and Compatible Gases

- Accessories

- Mounting Hardware (Optional), Instruction Manual

- Operating Temperature Range

- 20 to 120°F (-6 to 49°C)

- Connections Location

- Back (standard); others available upon request

- Maximum Pressure

- 20 psig (1.38 bar)

- Model

- 4001 Capsuhelic Differential Pressure Gauge

- Window Material

- Acrylic

- Zero Adjustment

- External adjustment screw

- Weight

- Approximately 12 oz (340 g)

Dwyer 4001 Capsuhelic Differential Pressure Gauge Trade Information

- Minimum Order Quantity

- 12 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Days after Acceptance (DA), Delivery Point (DP), Telegraphic Transfer (T/T), Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Main Export Market(s)

- Australia, South America, Middle East, Western Europe, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Dwyer 4001 Capsuhelic Differential Pressure Gauge

Dwyer 4001 Capsuhelic Differential Pressure Gauge

Dwyer Instruments 4001

Capsuhelic Differential Press. Gauge, 0-1 in H2O, brass case

Differential Pressure Gage, Range 0-1.0" w.c., For Vertical Scale Position Only.

The Capsuhelic gauge is designed to give fast, accurate indication of differential pressures. The gauge may be used as a readout device when measuring flowing fluids, pressure drop across filters, liquid levels in storage tanks and many other applications involving pressure, vacuum or differential pressure. Using the basic design of Dwyer's time-proven Magnehelic gauge, the Capsuhelic gauge contains a simple, frictionless movement that permits full scale readings as low as 0.5 in H2O. The pressure being measured is held within a capsule which is an integral part of the gauge. This containment of the pressure permits the use of the gauge on system pressures of up to 500 psig, even when differentials to be read are less than 0.1 in H2O. The diaphragm-actuated Capsuhelic gauge requires no filling liquid which might limit its outdoor applications. Zero and range adjustments are made from outside the gauge, and there is no need to disassemble the gauge in normal service. Note: May be used with Hydrogen. Order a Buna-N diaphragm. Pressures must be less than 35 psi.

Product Highlights

Brass case

0-1 in H2O

Precision and Durability Combined

Built with a powder-coated die-cast aluminum case and acrylic lens, the Dwyer 4001 Capsuhelic Differential Pressure Gauge offers long-lasting performance in demanding environments. Its precision machined components and 2% accuracy make it an effective choice for industries requiring meticulous air and compatible gas pressure measurements.

Flexible Installation and Easy Operation

Supporting both surface and panel mount configurations, this gauge adapts easily to various setups. It features an external zero adjustment screw for on-site calibration and clear analog display with a full-view front lens, allowing users to monitor differential pressure with ease and confidence.

FAQs of Dwyer 4001 Capsuhelic Differential Pressure Gauge:

Q: How do I install the Dwyer 4001 Capsuhelic Differential Pressure Gauge?

A: The Dwyer 4001 can be installed using either a surface or panel mount, depending on your application needs. The gauge includes a 1/8 NPT female threaded connection located at the back as standard. Optional mounting hardware and clear instructions are provided to simplify the installation process.Q: What types of media can this differential pressure gauge measure?

A: This gauge is specifically designed to measure the pressure of air and compatible gases only. It should not be used with incompatible fluids or corrosive gases to ensure safe operation and accurate readings.Q: Where can the Dwyer 4001 gauge be used?

A: The Dwyer 4001 is ideal for industrial settings such as HVAC systems, filtration monitoring, clean rooms, and duct pressure measurement. Its robust construction and precise performance make it suitable for a wide range of environments within its specified operating temperature range of 20 to 120F (-6 to 49C).Q: What process should I follow to adjust the zero setting?

A: To adjust the zero setting, simply use the external adjustment screw located on the gauge. This allows for quick recalibration in the field, ensuring continued accuracy even after installation or changes in atmospheric conditions.Q: When should I check or recalibrate my pressure gauge?

A: Periodic maintenance is advisable to maintain accuracy. It is recommended to check or recalibrate the gauge during routine equipment inspections, after cleaning, or whenever you observe discrepancies in pressure readings.Q: What are the benefits of using the Dwyer 4001 Capsuhelic gauge?

A: Key benefits include reliable and precise differential pressure readings, robust construction with powder-coated die-cast aluminum body, external zero adjustment for convenience, flexible mounting options, and a clear analog display for quick monitoring. These features help maintain optimal system performance and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Series 4000 Capsuhelic Differential Pressure Gage Category

Dwyer 4030 Capsuhelic Differential Pressure Gauge

Price 9871034100 INR

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of full scale

Scale Range : 030 inches of water gauge (inH2O)

Thread : 1/8 NPT Female

Seal Material : Silicone rubber gaskets

Dwyer 4050 Capsuhelic Differential Pressure Gauge

Price 9871034100 INR

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of full scale

Scale Range : 015 psi (or as specified)

Thread : 1/8 NPT Female

Seal Material : BunaN

Dwyer 4003 Capsuhelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of Full Scale

Scale Range : 03 Inches w.c. (Water Column)

Thread : 1/8 NPT Female Ports

Seal Material : Neoprene

Dwyer 4000-0 Capsuhelic Differential Pressure Gauge

Minimum Order Quantity : 12 Pieces

Accuracy : 2% of full scale

Scale Range : 00.5 in. water column (WC)

Thread : 1/8 female NPT ports

Seal Material : Silicone rubber

Send Inquiry

Send Inquiry