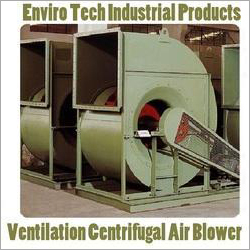

Ventilation Centrifugal Air Blower

Ventilation Centrifugal Air Blower Specification

- Air Flow

- Up to 20000 m3/hr

- Efficiency

- High

- Automation Grade

- Semi-Automatic

- Orientation

- Horizontal

- Usage & Applications

- Industrial ventilation, HVAC, dust collection, exhaust systems

- Power Source

- Electric

- Temperature

- Ambient

- Product Type

- Ventilation Centrifugal Air Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- <70 dB

- Processing Time

- Continuous

- Capacity

- 3000-20000 m3/hr

- Voltage

- 415 V

- Weight

- Approx. 120 kg

- Dimension (L*W*H)

- 850 x 550 x 820 mm

- Surface

- Powder Coated

About Ventilation Centrifugal Air Blower

Ventilation Centrifugal Air Blower

We offer high quality Ventilation Centrifugal Air Blower for various applications such as fume extraction, dust collection, drying, ventilation purpose, material conveying, cooling etc. We have carved a remarkable position as the successful centrifugal blowers manufacturer across nation. High efficiency fans that are used in our centrifugal blower promise low power consumption. As per the demand of the patron, different ranges of pressure and volume ratio are available.

Features:

-

Low power consumption

-

High efficiency fans

-

Accurate dimensions

-

Exceptional quality

Impellers/Rotors use for Ventilation Centrifugal Air Blowers:

Ventilation Inlines Air Blowers are very efficient and made for different types of Impellers or Rotors like Backward/forward Curved inclined bladed, Airfoil designs, Open Type, Multiblade Type, F type, Backward curved Impellers/Rotors, Forward curved Impellers/Rotors, etc.

Required Specifications for Ventilation Centrifugal Air Blowers:

- Air Volume

- Air Pressure

- Motor H.P.

- Blower R.P.M.

- Operating Temp

- Drive Type

- Construction of Material (M.O.C.)

Ceramic and Refractories Industries,

Chemical Factories,

Cement Plants,

Crucible Furnaces,

Furnaces like Oil,

Gas,

Cupola Furnaces,

Flour Mills,

Rolling Mills,

Boilers,

Textile Mills,

Cattle Feed Plants,

Pharmaceutical Industries,

Fertilizer Industries,

Plastic Machinery Plants,

Hot Mix Plants,

Iron and Steel Plants,

Paper Industries,

Process Industries,

and many more.

Use of Ventilation Centrifugal Air Blowers/Fans:

As Supply and Exhaust fans in Ventilation systems, In air handling units for air conditioning systems, In cold storage plants, For Fumes / Heat /Humidity / Smoke / Any other air Gases extraction and circulation in industrial plants/shed/covered-uncovered area, Industrial Blowers/Fans are widely used in Ventilation, Pollution Control, Fume Extraction, Dust collection, Induced Draft(ID Fans) and Forced Draft(F.D.Fans) for Boilers and Furnaces, Dust, suitable for various applications for Cooling, Humidification, Ventilation, Gas exhaust fans, Exhausters, fresh air supply, HVAC duties, Combustion for Burners, Recirculation of Fresh and United Air, etc.

Enviro Tech Industrial Products also Manufacturer, Supplier, Export, of Different Blowers, like Single Inlet Single Width Centrifugal Backward/Forward Curve Blowers (SISW Blowers), Airfoil Blowers, DIDW Blowers, Centrifugal Blowers, Air Blowers, Exhaust Blowers, Combustion Blowers, High Pressure Blowers, Low Pressure Blowers, Forced Draft Blowers(F.D.Fans), Induced draft Blowers(I.D.Fans), and all types of Industrial Fans.

Ventilation Centrifugal Air Blowers/Fans Features:

High efficiency, Low sound level, Compact Design, Large sizes can be dismantled, More Air with less HP, Easy in operation, Smooth in Running, Several versions available, etc.

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Engineered for Heavy-Duty Industrial Applications

This centrifugal air blower is designed for environments requiring continuous, efficient airflow. Its robust construction and corrosion-resistant finish accommodate indoor and outdoor installation, making it suitable for factories, warehouses, and process plants in India. The units horizontal orientation and base-mounted design simplify setup, while high-pressure performance ensures reliable dust collection and exhaust ventilation in demanding settings.

Efficient and Low-Maintenance Operation

Outfitted with backward curved blades and a dynamically balanced impeller, the blower provides high efficiency at lower noise levels. The air-cooled motor and epoxy-coated mild steel structure extend operational lifespan with minimal upkeep. Its drive options, protection class IP55, and three-phase voltage make this blower a dependable component in automated and semi-automatic systems.

FAQs of Ventilation Centrifugal Air Blower:

Q: How is the Ventilation Centrifugal Air Blower installed in industrial settings?

A: The blower is base mounted and suitable for both indoor and outdoor installations. Its compact dimensions (850 x 550 x 820 mm) and horizontal orientation ensure compatibility with most HVAC, ventilation, and dust collection setups. Professional installation is recommended to optimize airflow and electrical connections.Q: What type of environments can this air blower operate in?

A: This unit performs efficiently in ambient temperatures from -10C to 50C, making it ideal for a variety of industrial environments. The corrosion-resistant epoxy coating protects against harsh conditions, and its IP55 protection class shields against dust and moisture, ensuring reliable performance indoors and outdoors.Q: When should the maintenance of the centrifugal blower be performed?

A: The blower is engineered for low maintenance due to its durable mild steel construction and air-cooled system. However, periodic checksincluding blade inspection, motor lubrication, and drive alignmentare recommended for optimal performance during continuous operation.Q: Where can this blower be effectively utilized?

A: It is best suited for industrial ventilation, HVAC systems, dust collection processes, and exhaust applications in manufacturing plants, warehouses, and commercial buildings throughout India.Q: What are the benefits of using backward curved blades in this blower?

A: Backward curved blades promote higher efficiency and quieter operation by reducing turbulence. This design also minimizes the risk of clogging from dust, extending the blowers lifespan and maintaining consistent airflow in challenging environments.Q: How does the blower handle varying air flow requirements?

A: With motor power options from 3 HP to 25 HP and airflow capacity from 3,000 to 20,000 m/hr, the blower can be tailored for different industrial needs. The direct or V-belt drive types offer flexible speed and pressure adjustments, accommodating diverse application demands.Q: What safety and protection features are included with this blower?

A: The blowers IP55 protection class safeguards against dust ingress and water jets. Its voltage rating (415V/50 Hz/three-phase) and corrosion-resistant epoxy finish further enhance operational safety and durability in industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Fans Manufacturers India Delhi Category

SISW Centrifugal Fan

Automation Grade : Automatic

Surface : Polished/Standard Finish

Power Source : Electric

Usage & Applications : Industrial Ventilation and Cooling

Noise Level : Low

Orientation : Horizontal

Air Handling Unit Blower

Automation Grade : SemiAutomatic

Surface : Powder Coated

Power Source : Electric

Usage & Applications : Industrial Ventilation, Clean Room Air Supply, HVAC Systems

Noise Level : Low (Below 65 dB)

Orientation : Horizontal

Forward Curved Blower

Automation Grade : SemiAutomatic / Manual

Surface : Powder Coated/Anticorrosive

Power Source : Electric

Usage & Applications : HVAC, Ventilation, Industrial Air Handling, Dust Extraction

Noise Level : Less than 75 dB

Orientation : Horizontal

Gas Blower

Automation Grade : SemiAutomatic

Surface : Paint Coated

Power Source : Electric

Usage & Applications : Industrial Ventilation, Gas Circulation, Exhaust Systems

Noise Level : 75 dB(A)

Orientation : Horizontal

Send Inquiry

Send Inquiry