Gas Blower

Gas Blower Specification

- Orientation

- Horizontal

- Efficiency

- Above 85%

- Power Source

- Electric

- Air Flow

- Up to 5000 m/hr

- Temperature

- Upto 60C

- Automation Grade

- Semi-Automatic

- Usage & Applications

- Industrial Ventilation, Gas Circulation, Exhaust Systems

- Product Type

- Industrial Gas Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- 75 dB(A)

- Capacity

- 500-5000 m/h

- Voltage

- 220-240 V AC

- Weight

- Approx 80 kg

- Dimension (L*W*H)

- 700 x 430 x 560 mm

- Surface

- Paint Coated

About Gas Blower

- Highly durable

- Enhanced functional life

- Robust construction

- Consistence performance

- Air Volume

- Air Pressure

- Motor H.P.

- Blower R.P.M.

- Operating Temp

- Drive Type

- Construction of Material (M.O.C.)

- Pay Mode Terms: T/T (Bank Transfer)

Efficient Design and Robust Performance

Built with a backward curved impeller and dynamically balanced mild steel blades, this blower offers high efficiency and stability. The powerful motor, paired with an IP-55 protective enclosure and air-cooled system, ensures consistent performance even in demanding industrial environments.

Versatile Applications in Industry

Ideal for ventilation, gas circulation, and exhaust needs, this blower suits various factories, warehouses, and process plants. Its base mounted, flange-connected design supports flexible installation, while the wide capacity range handles diverse airflow demands, from 500 to 5000 m/h.

Reliability and Safety Assurance

The F Class insulation, IP-55 motor protection, and precision dynamic balancing ensure operational safety and extended life span. Rated for semi-automatic automation, this blower reduces maintenance downtime, supports rigorous usage, and maintains noise levels at a manageable 75 dB(A).

FAQs of Gas Blower:

Q: How is the gas blower installed and what is its mounting style?

A: The gas blower is base mounted, which means it should be securely fixed to a solid, level surface using bolts. Its flange connection type allows for straightforward attachment to ventilation ducts or other compatible systems, ensuring stability during operation.Q: What industrial applications is this gas blower suitable for?

A: This blower is ideal for industrial ventilation, gas circulation, and exhaust systems. Its robust design, high airflow capacity (up to 5000 m/h), and efficient mild steel impeller make it suitable for manufacturing plants, chemical industries, and process facilities.Q: When should I use a backward curved impeller on a blower?

A: A backward curved impeller should be chosen when efficient airflow, energy savings, and stable operation are priorities. This design reduces the risk of clogging, operates quietly, and provides high efficiency (>85%), making it ideal for continuous industrial use.Q: What benefits does the IP-55 rated motor and F Class insulation provide?

A: The IP-55 protection safeguards the motor against dust ingress and powerful water jets, enhancing lifespan in harsh industrial environments. F Class insulation increases thermal endurance, allowing the blower to operate safely at temperatures up to 60C without performance loss.Q: How does the dynamic balancing of the impeller contribute to performance?

A: Dynamic balancing ensures minimal vibrations during operation, leading to quieter performance (75 dB(A)), reduced wear on components, and extended service life. This feature is critical in continuous operations or sensitive environments where noise and reliability matter.Q: What are the main advantages of using this mild steel gas blower?

A: The key advantages are robust construction, high efficiency, reliable performance, ease of installation, and low maintenance needs. Its semi-automatic operation and paint-coated surface further enhance durability and usability in a range of industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Fans Manufacturers India Delhi Category

Low Pressure Blower

Product Type : Low Pressure Blower

Material : Mild Steel

Usage & Applications : Industrial Ventilation, Air Cooling, HVAC, Dust Extraction

Orientation : Horizontal

Surface : Powder Coated

Dimension (L*W*H) : 1250 x 820 x 950 mm

F.D.Fans

Product Type : Industrial Exhaust Fan

Material : Mild Steel

Usage & Applications : Industrial Ventilation, Warehouses, Factories

Orientation : Wall Mounted

Surface : Powder Coated

Dimension (L*W*H) : 600 mm x 600 mm x 300 mm

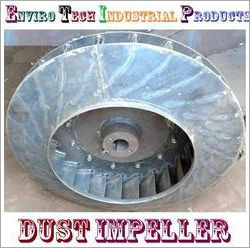

Dust Impeller

Product Type : Dust Impeller

Material : Metal

Usage & Applications : Industrial

Surface : Polished

Cross Flow Fan & Blower

Product Type : Cross Flow Fan & Blower

Material : Metal

Usage & Applications : Industrial Cooling/Blowing

Orientation : Horizontal

Dimension (L*W*H) : Wheel 100MM

Send Inquiry

Send Inquiry