Low Pressure Blower

Low Pressure Blower Specification

- Measurement

- Air Volume

- Instruments Type

- Blower

- Display Type

- Analog

- Orientation

- Horizontal

- Air Flow

- Adjustable

- Efficiency

- High (>85%)

- Automation Grade

- Semi-Automatic

- Power Source

- Electric

- Temperature

- Up to 60C

- Usage & Applications

- Industrial Ventilation, Air Cooling, HVAC, Dust Extraction

- Product Type

- Low Pressure Blower

- Material

- Mild Steel

- Cooling System

- Air Cooled

- Noise Level

- Low (<80 dB)

- Processing Time

- Continuous

- Capacity

- 500-30000 m/hr

- Voltage

- 220-240 V

- Weight

- 185 kg

- Dimension (L*W*H)

- 1250 x 820 x 950 mm

- Surface

- Powder Coated

About Low Pressure Blower

- Comes with impellers that are available in different designs which are dynamically balanced for providing stable & vibration free running and suit the different application needs

- Suitable for applications including cooling & conveying for gases, combustion, material and others

- Capacities up to 150000 m3/hr.

- Pressure up to 1200 mm WG.

- Fabricated with heavy gouge using M.S & S.S. sheet

- Pay Mode Terms: T/T (Bank Transfer)

Efficient Industrial Air Handling

This blower delivers high capacity air movement with low power consumption, offering adjustable airflow and excellent static pressure capabilities. Its backward curved impeller and air-cooled system ensure optimal performance across industrial ventilation, dust extraction, cooling, and HVAC processes.

Robust Design for Maximum Durability

Manufactured using heavy-duty welded mild steel and featuring a powder coated surface, this blower is built to withstand harsh environments. The double sealed ball bearings and industrial-grade paint finish further enhance longevity, making it suitable for both indoor and outdoor placement.

Versatile Installation and Operation

With standard frame sizes, base mounting, and options for direct or belt drive, this blower provides flexible integration into existing setups. The analog display and semi-automatic controls facilitate easy monitoring and adjustment, improving operational efficiency in various industrial contexts.

FAQs of Low Pressure Blower:

Q: How do I install the low pressure blower with a base mounted setup in my facility?

A: To install the blower, select a stable, level surface for base mounting. Ensure sufficient clearance for the air inlet diameter (250600 mm) and secure the blower using industrial-grade fasteners. Connect to a power source of 220-240 V and verify that the ventilation system aligns with the blowers horizontal orientation and available drive type (direct or belt driven).Q: What types of industrial applications can this blower be used for?

A: This blower is ideal for industrial ventilation, HVAC systems, air cooling, and dust extraction. Its high efficiency and adjustable air flow make it suitable for various continuous air handling requirements across manufacturing plants, workshops, warehouses, and commercial settings.Q: When should I choose a backward curved impeller-type blower over other impeller designs?

A: Backward curved impeller blowers are recommended when you need high efficiency, reduced noise, and low power consumption. They perform exceptionally well under continuous processing and when handling large volumes of air at medium static pressures, making them preferable for indoor and outdoor industrial usage.Q: Where can the blower be used, and is it suitable for outdoor environments?

A: The blower is designed for both indoor and outdoor environments. Its corrosion-resistant mild steel construction and industrial-grade powder coated finish protect against harsh environmental factors, ensuring reliable operation and longevity regardless of placement.Q: What is the process for adjusting air flow in this blower?

A: Air flow can be adjusted using the analog display and semi-automatic controls. Depending on the system configuration, you may vary the speed via the motor or adjust dampers or inlet guides for fine-tuning, allowing flexibility to meet changing process requirements.Q: How does this blower benefit my operations in terms of efficiency and maintenance?

A: With an efficiency rating above 85% and low noise emission (<80 dB), this blower helps reduce energy costs and operational disturbances. The double sealed ball bearings, air-cooled system, and powder-coated surface minimize maintenance intervals and enhance equipment longevity, ensuring consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Fans Manufacturers India Delhi Category

Commercial Blower

Material : Mild Steel

Product Type : Industrial Blower

Usage & Applications : Use in cooling ventilation dust control industries

Efficiency : Energy Efficient

Processing Time : Continuous

Weight : Depends on customization

F.D.Fans

Material : Mild Steel

Product Type : Industrial Exhaust Fan

Usage & Applications : Industrial Ventilation, Warehouses, Factories

Efficiency : Energy Efficient

Processing Time : Continuous

Weight : Approx. 18 kg

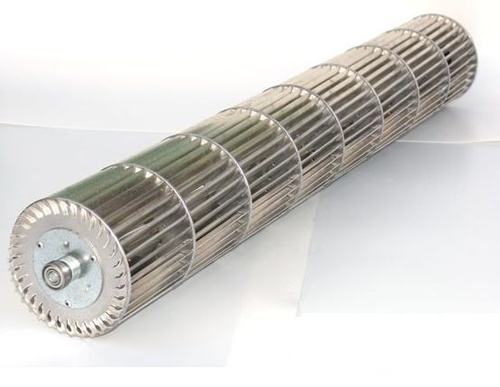

Impeller for Air Curtain

Material : Aluminium/Stainless Steel

Product Type : Impeller

Usage & Applications : Air curtains and ventilation systems

Efficiency : Energy efficient

Processing Time : Customizable based on requirements

Weight : Lightweight

Send Inquiry

Send Inquiry