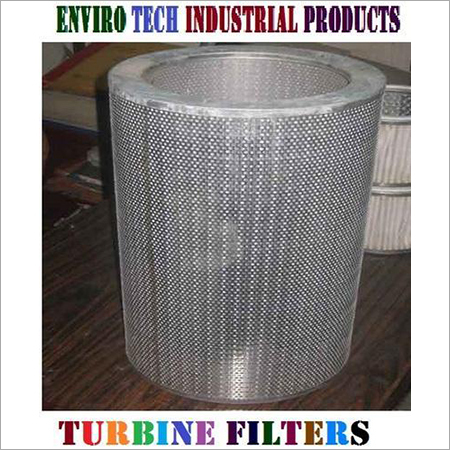

Turbine Filters

Turbine Filters Specification

- Filter Type

- Pleated Cartridge

- Cleaning Method

- Washable / Replaceable

- Connecting Type

- Flanged / Clamp connection

- Media Type

- Wire mesh / Synthetic fiber

- Efficiency (%)

- Up to 99%

- Temperature Range

- -20C to +120C

- Pressure

- Max. 15 bar

- Capacity

- High Dust Retention

- Flow Rate

- 1500-5000 CFM (customizable)

- Filtration Grade

- Industrial Grade

- Condition

- New

- Material

- Stainless Steel Mesh and Aluminum

- Mesh

- Fine mesh construction

- Diameter

- Customizable (Standard: 24-30 inch)

- Construction

- Rugged Cylindrical Design

- Medium Filter

- Air / Gas

- Weight

- Approx. 5-8 kg

- Shape

- Cylindrical

- Feature

- High dust holding capacity and corrosion resistance

About Turbine Filters

Turbine Filters are Manufactured and Supplied by us to fulfill the requirements of the clients. High performance, superb visibility and easy operation are the qualitative features of our range of Turbine filters and widely preferred by the buyers. Our Turbine Filters products are modern and reliable and is tested on diverse parameters to make the range free from all drawbacks. We offer the filters at competitive prices. They ensure high efficient filtration of dust and other contaminates even in the most polluted environments.

Features

- Superior performance

- Longer working life

- Easy to operate

- Robust construction

Gas turbine filters and cartridges for gas turbines are modern and reliable. They ensure high efficient filtration of dust and other contaminates even in the most polluted environments.

Application: These are suitable for different make turbines such as:Triveni, BHEL, Apebellis, DLF, Metropolitan Vickers, Kessels, Thermodyne and other make.

Flow Rate: These can be supplied for different flow rates of turbine such as: 4, 8, 15, 25,40, 45, 80, 100, 200 GPM etc

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Engineered for High Performance

Our turbine filters are designed to deliver reliable air and gas filtration in the most demanding industrial settings. The fine mesh construction and pleated cartridge design offer exceptional dust holding capacity, with rugged stainless steel and aluminum ensuring long-term performance. Each filter is capable of handling high flow rates and differential pressures while remaining resistant to corrosion.

Versatile Construction and Customization

Adaptability is a crucial aspect of our turbine filters. With customizable diameters, vertical or horizontal mounting options, and various connecting types such as flanged or clamp, they are suitable for a wide range of installations. The modular design caters to multiple filtration needs, from compressor protection to engine efficiency and blower applications.

FAQs of Turbine Filters:

Q: How are turbine filters installed in industrial equipment?

A: Turbine filters can be mounted both vertically and horizontally, depending on your systems design. They are compatible with flanged or clamp connections, providing flexibility for easy integration into compressors, blowers, turbines, or engine assemblies.Q: What types of applications are suitable for these turbine filters?

A: These filters excel in turbine inlet air filtration, compressors, blowers, and various industrial engines. Their high dust retention capability and corrosion-resistant construction make them ideal for harsh environments and high-efficiency operations.Q: When should the turbine filter be cleaned or replaced?

A: Cleaning or replacement intervals depend on the operating environment and dust load. Filters with washable media can be reused after cleaning, while replaceable options should be changed once their efficiency drops or maximum differential pressure (450 Pa) is reached.Q: Where are these turbine filters manufactured and supplied from?

A: We manufacture and supply these turbine filters in India, ensuring compliance with industrial standards, and we support distribution to traders, wholesalers, and end users across multiple sectors.Q: What benefits do pleated cartridge and fine mesh designs provide?

A: Pleated cartridge filters combined with fine mesh construction help maximize filtration surface area, resulting in higher dust holding capacity, improved efficiency (up to 99%), and prolonged filter life, even in challenging conditions.Q: How do the material choices impact filter performance and durability?

A: Aluminum and stainless steel end caps with neoprene or EPDM gaskets offer excellent corrosion resistance, while the stainless steel mesh and synthetic fiber media ensure robust performance in a wide temperature range and exposure to high dust loads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Manufacturers In India Delhi Category

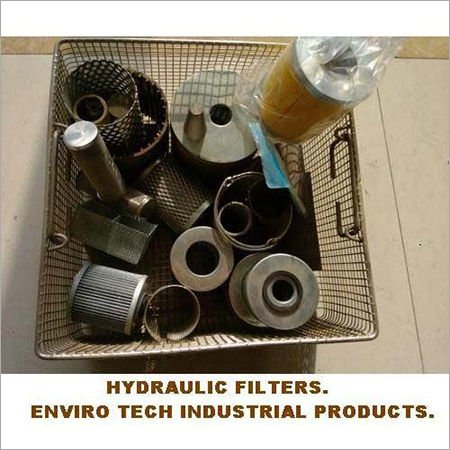

Hydraulic Filters

Filter Type : Return Line / Suction / Pressure line

Mesh : Fine Filtration Mesh

Weight : Approx. 350 g

Condition : New

Connecting Type : Other, Threaded / Flange

Medium Filter : Other, Hydraulic Oil

Air Washer Filter

Filter Type : Panel / Air Washer Filter

Mesh : Multilayered mesh

Weight : Lightweight, 25 Kg (approx. depending on size)

Condition : New

Connecting Type : Other, Flange type / Channel Frame

Medium Filter : Other, Synthetic NonWoven

Oven Air Filters

Filter Type : Air Filter

Mesh : Fine mesh for improved filtration

Weight : Approx. 0.8 1.5 kg (varies by size)

Condition : New

Connecting Type : Other, Dropin / Slidein

Medium Filter : Other, Aluminum mesh

Railway Air Conditioning Filter

Filter Type : Panel Filter

Mesh : Fine Mesh

Weight : Approx. 2.5 kg

Condition : New

Connecting Type : Other, SlideIn Fit

Medium Filter : Other, Synthetic Fiber

Send Inquiry

Send Inquiry