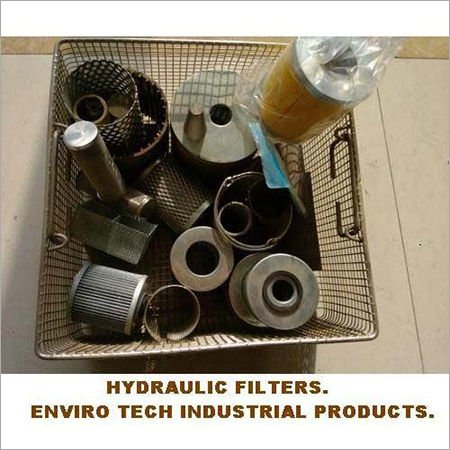

Hydraulic Filters

Hydraulic Filters Specification

- Temperature Range

- -20C to +80C

- Capacity

- Standard / Custom sizes available

- Efficiency (%)

- Up to 99%

- Connecting Type

- Threaded / Flange

- Media Type

- Oil / Hydraulic Fluid

- Filtration Grade

- Medium to High

- Filter Type

- Return Line / Suction / Pressure line

- Flow Rate

- Up to 100 LPM

- Cleaning Method

- Replaceable / Washable

- Pressure

- Up to 10 Bar

- Condition

- New

- Material

- Stainless Steel Mesh, Aluminum End Caps

- Mesh

- Fine Filtration Mesh

- Diameter

- Approx. 60 mm

- Construction

- Cylindrical, Welded Seam

- Medium Filter

- Hydraulic Oil

- Weight

- Approx. 350 g

- Shape

- Cylinder

- Feature

- Removes particulate contaminants from hydraulic oil, Easy installation, Enhanced durability

About Hydraulic Filters

We are instrumental in providing our clients a comprehensive range of Hydraulic Filters. Backed by a team of experts, these products are manufactured using high grade raw material and advance technology by our skilled professionals. Our offered range is precision-designed, in order to meet the international standards. Furthermore, these filters are availed in various sizes and other related specifications as per the varied needs of our valuable clients. Our Hydraulic Filters range is stringently tested on various parameters to assure it on counts of quality.

Features

- Washable

- High dust holding capacity

- Reliability

- High filtration capacity

Specifications:

For Pressure line and Return line filters:

| Type: | High Pressure Elements |

| Size: | Multiple Length Elements |

| Filtration Media & Micron: | Micro glass Beta 75 in 1,3,5,10,& 25 Micron |

| Temperature Range: | 10 oC to 100 oC |

For Suction Strainers:

| Size: | Multiple Length Elements |

| Filtration Media & Micron: | Stainless steel woven wire 125 Micron |

| Application: | For use with Hydraulic Fluids, Oil coolants, Cutting oil & Lubricants. |

Other Information

- Pay Mode Terms: T/T (Bank Transfer)

Superior Filtration and Durability

Built with a fine stainless steel mesh and robust welded seam construction, these hydraulic filters achieve medium to high filtration efficiency. The anti-corrosive coated end caps and resilient seal materials (Buna-N or Viton) ensure longevity, even in harsh conditions, while vibration resistance maximizes reliability for continuous, heavy-duty usage.

Flexible Installation and Maintenance

The filters are compatible with vertical or horizontal mounting orientations and feature threaded or flange connections for straightforward setup. Available in standard and custom sizes, maintenance is simplified through replaceable or washable filter options, allowing users to easily adapt to operational needs and minimize equipment downtime.

Wide Application Range

Designed to meet the requirements of construction machinery, industrial machines, and agricultural tractors, these hydraulic filters support mineral oil-based fluids. Their sturdy cylindrical design and pressure tolerance up to 10 Bar make them versatile for return line, suction, or pressure line installation in varied hydraulic systems.

FAQs of Hydraulic Filters:

Q: How do I select the right hydraulic filter for my equipment?

A: Choose a filter based on your application, fluid compatibility (mineral oil-based), needed micron rating (10 m to 40 m), mounting orientation, and flow rate requirements. Standard and custom sizes are available to accommodate different hydraulic systems.Q: What are the benefits of using hydraulic filters with anti-corrosive coating?

A: Hydraulic filters with anti-corrosive coated aluminum end caps offer enhanced resistance to rust and degradation, ensuring longer service life and optimal protection in harsh industrial or outdoor environments.Q: Where can these hydraulic filters be installed in hydraulic systems?

A: These filters are suitable for installation in return lines, suction lines, or pressure lines within hydraulic systems used in construction equipment, industrial machines, and agricultural tractors.Q: When should I replace or clean the hydraulic filter?

A: Depending on operating conditions and use, the filter should be replaced or washed every 12 months or sooner if flow rate decreases or contamination levels are high, to maintain optimal system performance.Q: What is the recommended process for filter maintenance?

A: For routine maintenance, inspect the filter regularly. Replace with a new filter if its non-washable, or clean it with compatible cleaning methods if washable. Always follow the manufacturers maintenance guidelines to ensure efficiency.Q: Which seal materials are available for these filters and what are their advantages?

A: These filters use Buna-N or Viton seals. Buna-N offers excellent oil resistance for general hydraulic fluids, while Viton provides superior resistance to chemicals and higher temperatures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filters Manufacturers In India Delhi Category

Fuel Filter

Temperature Range : Not available

Shape : Round

Construction : Other, Cylindrical

Capacity : Not available

Weight : Not available

Filtration Grade : Other, Not available

Box Type Hot Air Filters

Temperature Range : Up to 120C

Shape : Rectangular/Box

Construction : Other, Box Type, Rigid Construction

Capacity : Customized as per requirement

Weight : Varies by size (typically 1.5 to 6 kg)

Filtration Grade : Other, Pre Filter, Medium Filter

EDM Filter

Temperature Range : 20C to 80C

Shape : Round

Construction : Other, Cylindrical, Pleated, Rigid

Capacity : Depends on Model & System (up to 8000 litres)

Weight : Approx. 250 g to 1 kg

Filtration Grade : Other, Fine / Precision

Railway Air Conditioning Filter

Temperature Range : 10C to 70C

Shape : Round

Construction : Other, Robust, Heavy Duty Frame

Capacity : Long Service Life

Weight : Approx. 2.5 kg

Filtration Grade : Other, Pre/Primary

Send Inquiry

Send Inquiry